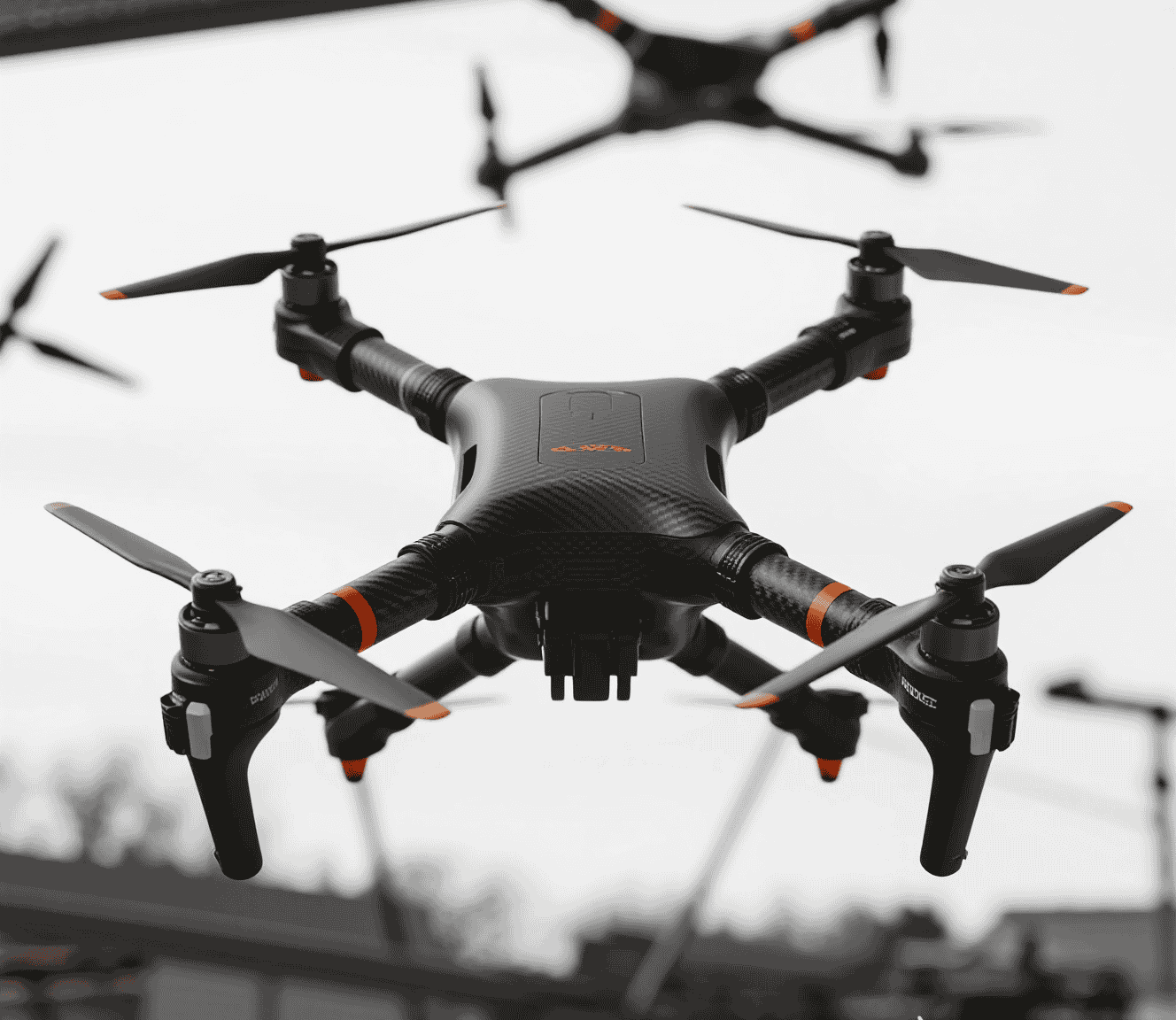

Why Weight Reduction Matters for Every Drone Manufacturer

Every serious drone manufacturer knows that every gram matters. In aerial engineering, weight dictates endurance, flight stability, and payload capability. Cutting even 10% can mean longer battery life and wider operational range. Imagine reducing weight by 40% without sacrificing strength. CarbonCore Dynamics offers that through advanced carbon fiber tubes—changing the design game for engineers.

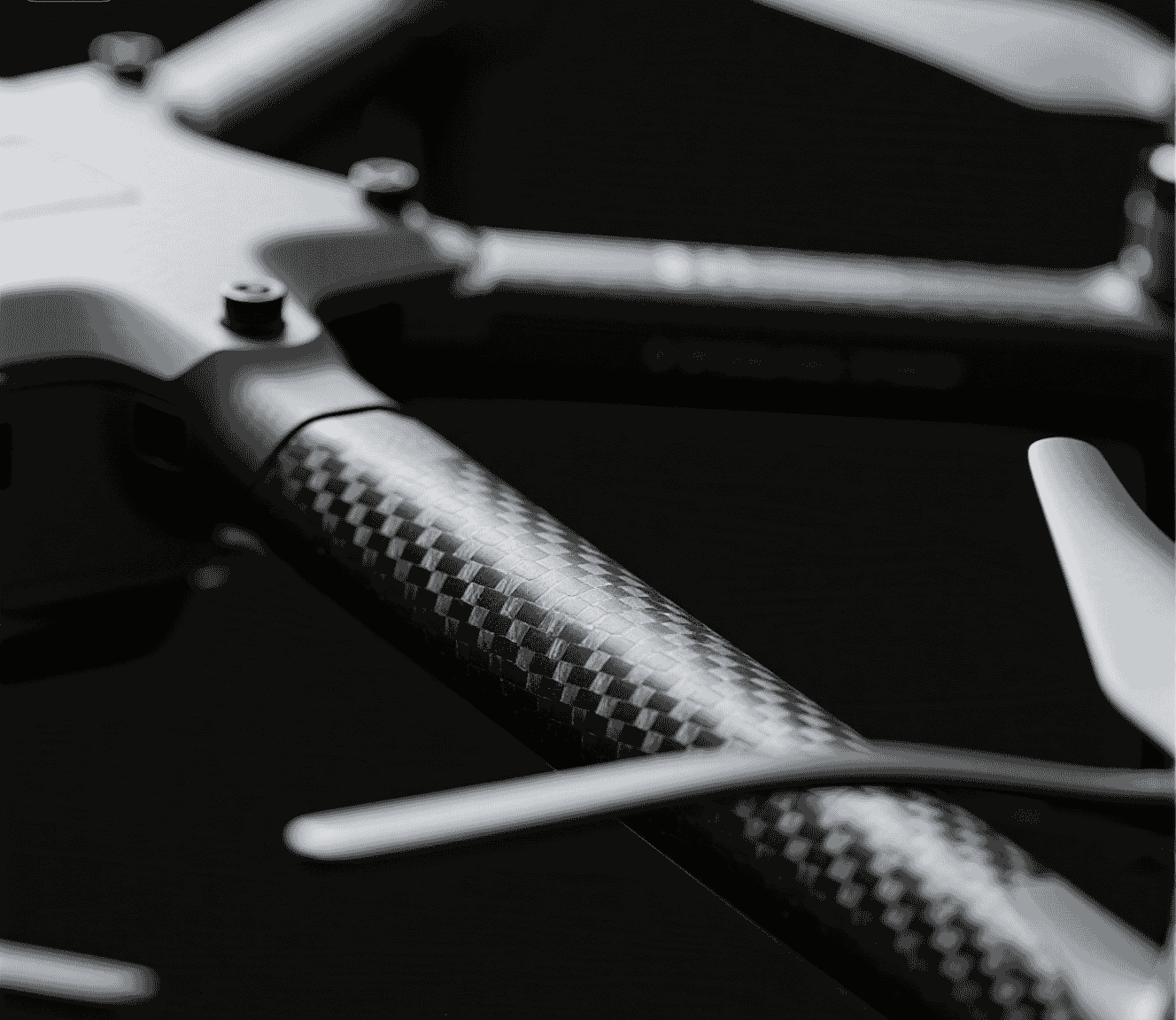

Why Carbon Fiber Matters in Drone Design

Aluminum once dominated frame construction. Strong? Yes. But heavy. Carbon fiber changes the equation. It offers a stunning strength-to-weight ratio, giving drones rigid frames that resist deformation without adding bulk. The result—more lift efficiency, smoother maneuverability, and higher crash resilience.

Integrating Carbon Fiber Tubes in Drone Design

Modern aerial platforms don’t just use straight rods. They blend carbon fiber square tubing for arms, curved carbon fiber tubing for aerodynamic shapes, carbon fiber rectangular tubing for mounting stability, and oval carbon fiber tube designs for reduced drag. By selecting the right shape for each structural role, engineers can fine-tune stiffness, torsion resistance, and airflow behavior.

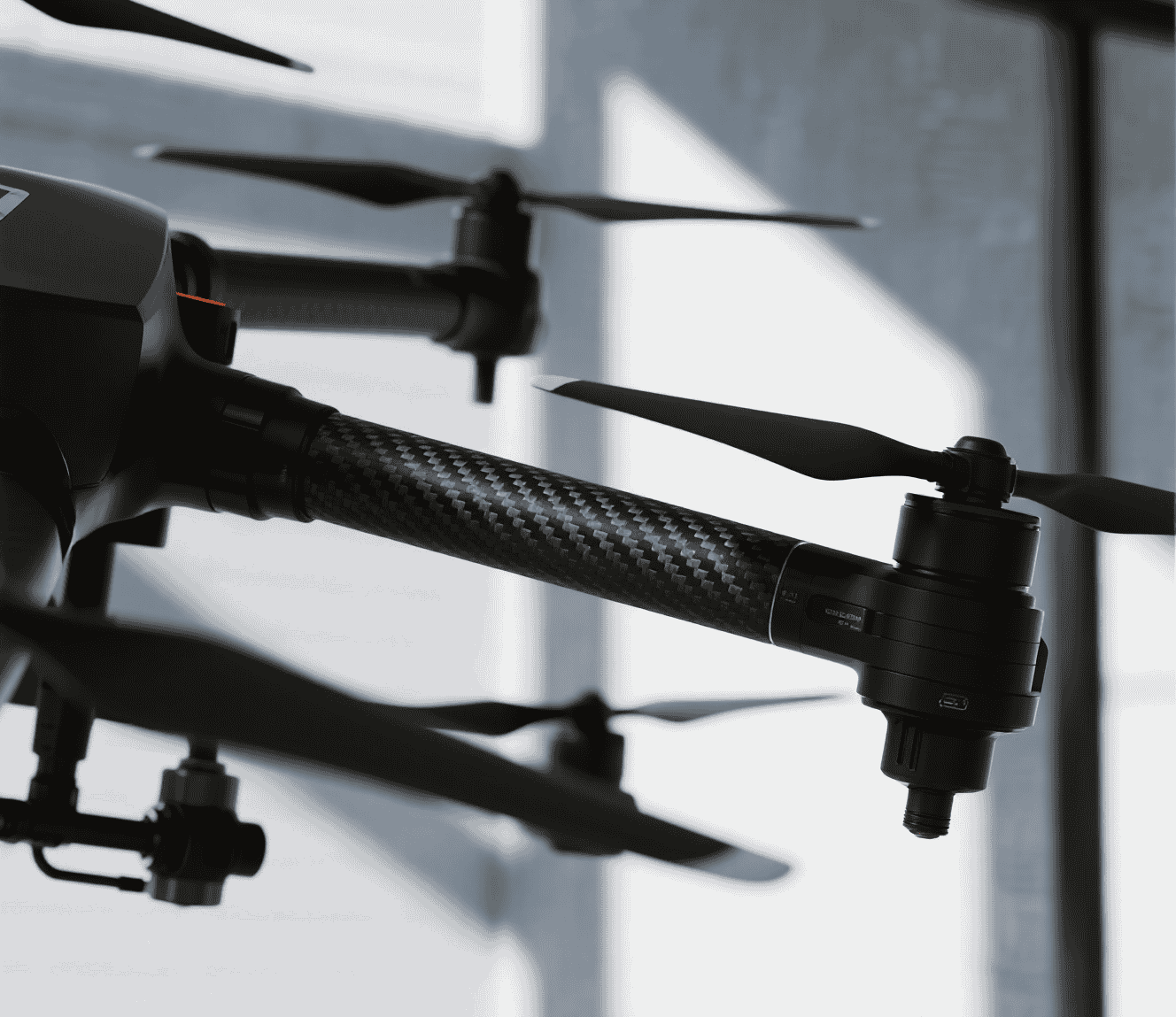

Performance Gains Due to Weight Reduction

Replacing heavier materials with CarbonCore Dynamics tubes slashes mass dramatically. A 40% reduction means:

Extended Flight Times — less strain on motors

Improved Agility — faster directional changes without wobble

Higher Payload Capacity — room for better cameras or sensors

Lower Energy Use — smaller batteries can achieve the same range

One drone manufacturer reported that after switching, their quadcopter’s flight time jumped from 25 minutes to nearly 38 minutes per charge.

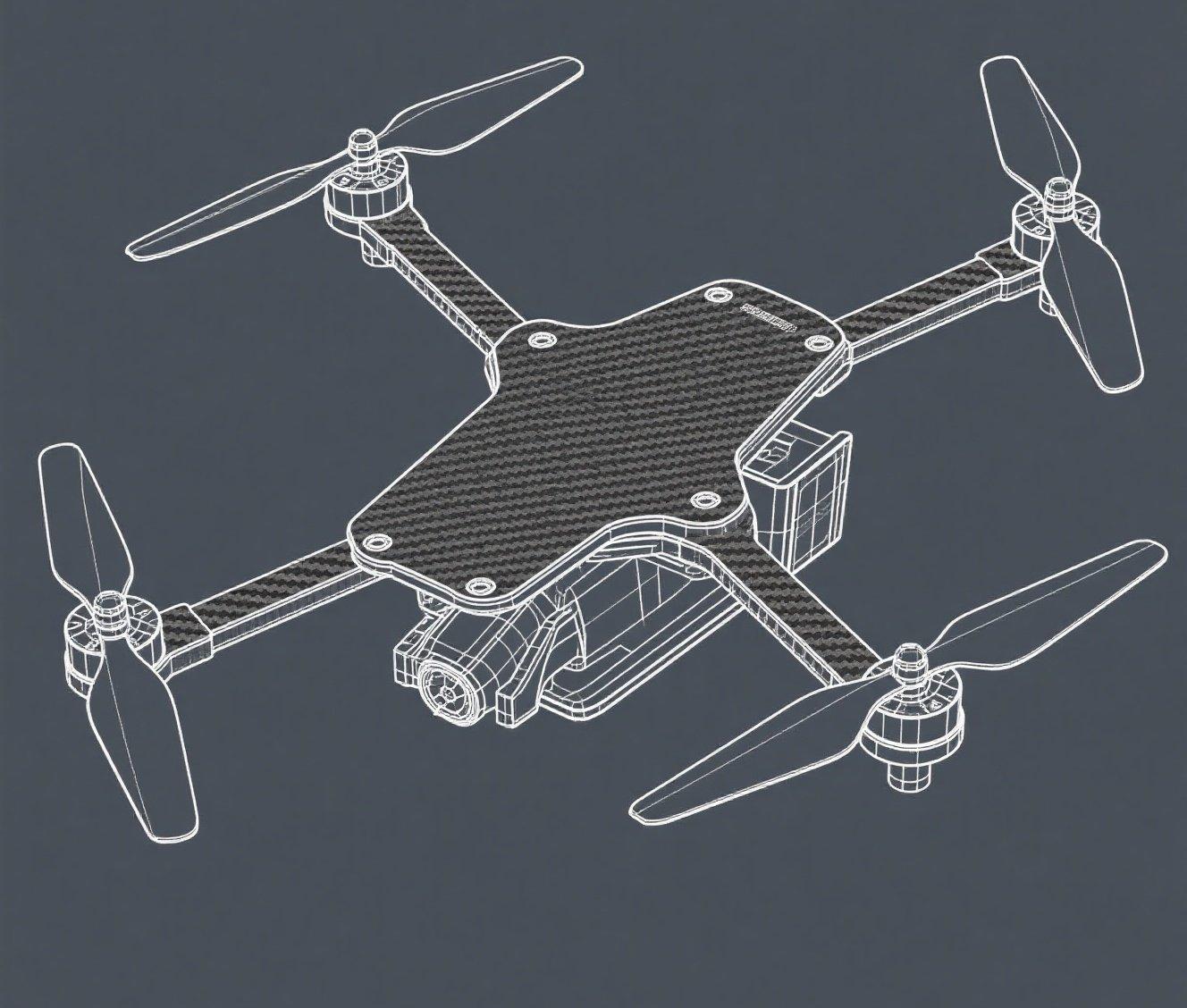

Drone Types Benefiting Most from Carbon Fiber Tubes

Not every platform needs ultra-light builds, but several categories thrive with this material:

Long-range Survey Drones — less weight means bigger coverage per flight

Racing Drones — higher acceleration, sharper cornering

Cinematography Platforms — steadier shots due to reduced vibration transfer

Agricultural Sprayers — more liquid payload without exceeding motor limits

Search-and-Rescue Units — faster deployment with extended hover endurance

Innovation & Research Trends in Drone Design

Carbon fiber tubes are no longer just raw materials—they’re engineered components. CarbonCore Dynamics invests in resin chemistry, weave pattern optimization, and hybrid tube geometries that resist microfractures. Expect more drones using blended structures—straight tubes where stiffness rules, curved profiles where drag reduction matters, and reinforced joints where repeated stress occurs.

Real-World Case Study: Drone with Continuous Fiber Reinforcement

A mid-size drone manufacturer faced a challenge: their fixed-wing UAV couldn’t carry the desired mapping camera without cutting flight range. After adopting continuous fiber-reinforced carbon fiber square tubing for the wing spars and curved carbon fiber tubing for fuselage shaping, total weight dropped by 38%. That small difference gave them enough range to complete surveys in a single flight instead of two. Labor costs dropped, mission turnaround time improved, and customers noticed the faster delivery.

Why CarbonCore Dynamics Carbon Fiber Tubes Matter

Off-the-shelf carbon fiber tubes can work, but not all are equal. CarbonCore Dynamics focuses on aerospace-grade prepreg materials, precisely cured for consistent wall thickness and strength distribution. Their catalog spans carbon fiber rectangular tubing for mounting systems, oval carbon fiber tube profiles for streamlined airflow, and ultra-light square tubing for motor arms. Each design balances stiffness, shock absorption, and manufacturing precision.

Cost vs Value for Drone Manufacturers

Yes, carbon fiber tubes cost more upfront than aluminum or fiberglass. However, the ROI appears in:

Fewer replacements from damage

Lower energy costs per flight

Higher mission capacity per drone

Better customer satisfaction from improved performance

When to Choose CarbonCore Dynamics

Choose CarbonCore Dynamics carbon fiber tubes when:

Your drone needs maximum endurance for mapping or surveillance

You require frame stiffness under high wind loads

Your design benefits from weight reduction for larger payloads

Aesthetics matter, and clean, sleek profiles are preferred

Final Thoughts

For any forward-thinking drone manufacturer, CarbonCore Dynamics offers a practical pathway to cut frame weight by 40%, unlock more flight time, and push aerial performance beyond expectations. With the right mix of square, curved, rectangular, and oval carbon fiber tubing, the sky isn’t just the limit—it’s the beginning.