مقدمة: لماذا يكافح المهندسون في اختيار أنابيب ألياف الكربون

A أنبوب ألياف الكربون تبدو بسيطة للوهلة الأولى. طويلة وسوداء وأنيقة. ومع ذلك فإن اختيار الدرجة أو المظهر الخاطئ يمكن أن يدمر الأداء ويستنزف الميزانيات. غالبًا ما يواجه المهندسون مفاضلات بين الوزن والقوة والصلابة والتكلفة. ومع وجود العديد من الاختلافات - الأنبوب العازل المصنوع من ألياف الكربون، والأنبوب الدائري المصنوع من ألياف الكربون، والأنبوب المربع المصنوع من ألياف الكربون، والأنبوب المصنوع من ألياف الكربون المنضب، فإن هامش الخطأ يكون مرتفعًا.

من أذرع الطيران إلى إطارات الدراجات، فإن اختيار الشكل المناسب مثل أنبوب ألياف الكربون بقياس 1 بوصة أو حتى أنبوب ضخم من ألياف الكربون بقياس 4 بوصات يمكن أن يحدد نجاح المشروع. دعونا نتعمق في الأخطاء الثمانية التي غالبًا ما تُرتكب ونحدد مسارات أكثر ذكاءً للمشترين والمهندسين على حد سواء.

1: تجاهل تطابق الألياف والمصفوفة الصحيحة في أنابيب ألياف الكربون

يعتمد كل أنبوب من ألياف الكربون على جزأين: الألياف نفسها والراتنج المحيط بها. يركز المهندسون في بعض الأحيان على درجة الألياف فقط بينما ينسون كيف تؤثر مصفوفة الراتنج على الأداء. وتتعامل الراتنجات القائمة على الإيبوكسي مع الإجهاد بشكل أفضل بكثير من راتنجات البوليستر، خاصةً في المشاريع عالية الإجهاد.

الحل: اسأل الموردين دائمًا عن كل من الألياف والراتنج. قد يفشل أنبوب من ألياف الكربون مقاس 1.5 بوصة مع نظام راتنج ضعيف أسرع من أنبوب دائري من ألياف الكربون أرق مع مصفوفة أقوى.

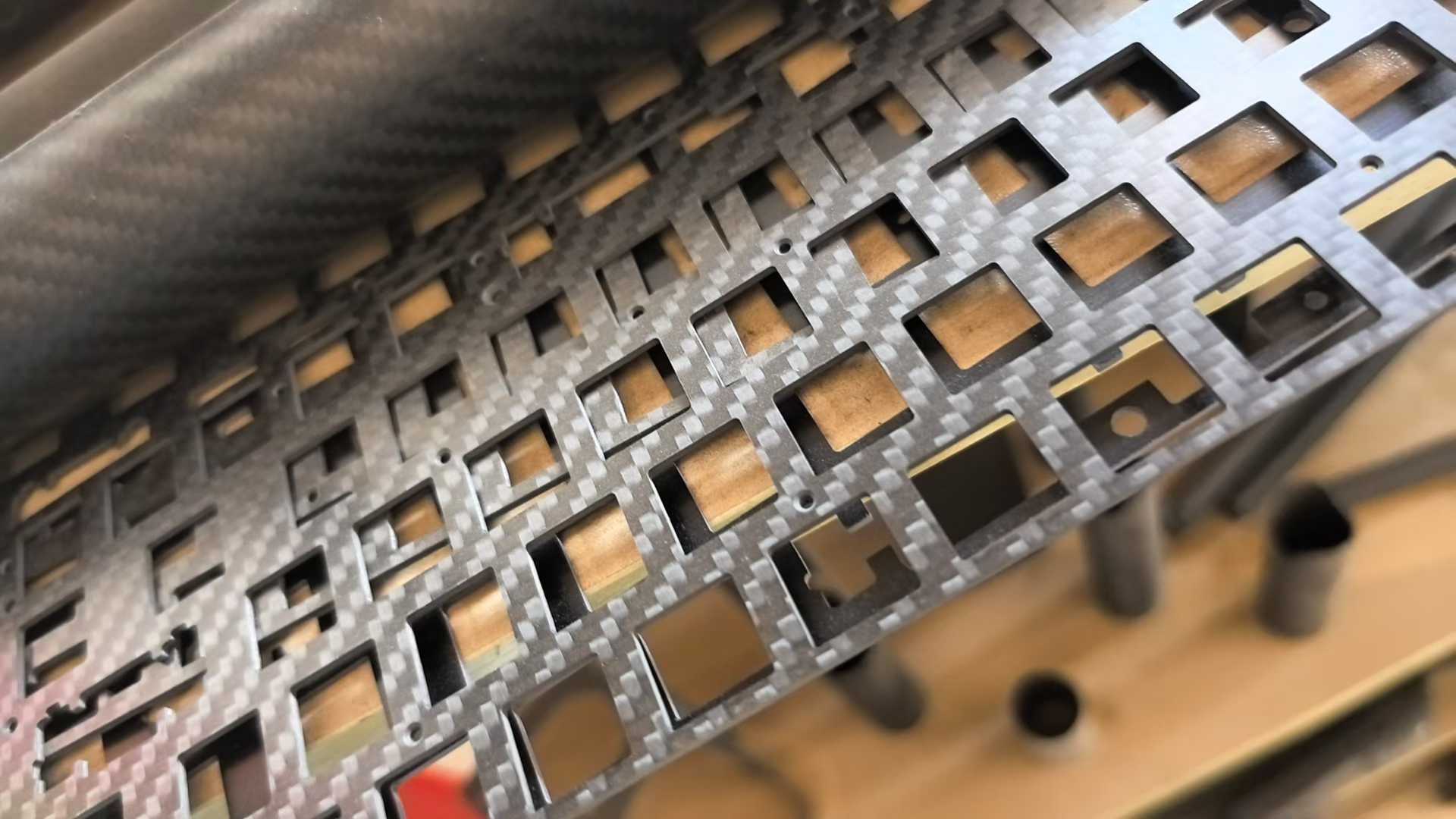

2: التغاضي عن الفراغات وعيوب التصنيع في الأنابيب المسحوبة والملفوفة

يمكن أن تؤثر فقاعات الهواء والبقع الغنية بالراتنج والتجاعيد في التصفيف على قوة الأنبوب. عادةً ما تكون خيارات الأنابيب المصنوعة من ألياف الكربون المنثورة أكثر اتساقًا، لكنها تفتقر إلى نفس التحكم في الاتجاه الذي توفره الأنابيب الملفوفة. المهندسون الذين يتخطون الفحص يخاطرون بأعطال خفية.

الحل: لا تعمل إلا مع البائعين الذين يقدمون شهادات الجودة وتقارير الفحص البصري. يمكن أن تؤدي الفراغات الصغيرة في الأنبوب المستطيل المصنوع من ألياف الكربون إلى حدوث تشققات تحت الضغط.

3: إهمال أنماط الفشل مبكراً في تصميم أنابيب ألياف الكربون

على عكس الفولاذ، تفشل المواد المركبة بطرق متعددة - التشقق أو التفكك أو تكسر الألياف. يمكن أن يعني تصميم أنبوب مربع من ألياف الكربون دون تحليل أحمال الانحناء فشلًا مبكرًا.

الحل: إجراء عمليات محاكاة للضغوط المتوقعة والنظر في اختبار النماذج الأولية. يجب تصميم أنبوب 1 من ألياف الكربون لأذرع الروبوتات من أجل القص والالتواء، وليس فقط الشد المحوري.

المراجع:

1. ألياف الكربون المثالية للطائرات بدون طيار: مواد الصفائح والخيارات

2. كيف تقطع أنبوب ألياف الكربون؟

3. فهم اختبارات الصلابة والضغط لأنابيب ألياف الكربون

4. ألياف الكربون مقابل قضيب الجرافيت: أيهما يناسب احتياجاتك بشكل أفضل

5. أوقفوا كوارث الطائرات بدون طيار! كيف تغير تقنية ثني أنابيب ألياف الكربون عالية الأداء كل شيء

4: خصم تباين الخواص والاتجاهات في أنابيب ألياف الكربون

لا تتصرف ألياف الكربون بنفس الطريقة في كل اتجاه. قد يقاوم الأنبوب العازل المصنوع من ألياف الكربون المقوى على طوله فقط التمدد ولكنه ينكسر عند الالتواء. وغالبًا ما يفترض المهندسون أداءً متساوي الخواص على غرار المعادن، وهو ما قد يكون كارثيًا.

الحل: حدد اتجاهات الألياف بعناية. بالنسبة لأعمدة الدوران، ادمج الطبقات أحادية الاتجاه مع الأقمشة المنسوجة. بالنسبة لأذرع الطيران الفضائية، فإن أنبوب ألياف الكربون 4 بوصة مع زوايا متعددة الطبقات يعالج الالتواء بشكل أفضل.

5: تخطي الاختبارات غير المدمرة وتخطيط التفتيش

لا يختبر بعض المهندسين إلا في المرحلة النهائية. وفي ذلك الوقت، يكلف إصلاح العيوب أكثر بكثير. تكتشف الاختبارات غير المدمرة مثل الفحص بالموجات فوق الصوتية أو المسح بالأشعة السينية التفكك في وقت مبكر.

الحل: خطط لطرق الفحص قبل الإنتاج بكميات كبيرة. يمكن فحص دفعة من الأنابيب الدائرية المصنوعة من ألياف الكربون بسرعة، مما يمنع عمليات السحب في المستقبل.

رقم 6: سوء تقدير التكلفة مقابل فوائد دورة حياة أنابيب ألياف الكربون

غالبًا ما يطارد المشترون الخيار الأرخص مقدمًا. قد يفشل أنبوب من ألياف الكربون مقاس 1.5 بوصة بعد عامين، بينما يستمر خيار أعلى درجة لمدة عقد من الزمن. على مدار دورة حياة كاملة، يتحول الرخيص إلى غالي الثمن.

الحل: تقييم التكلفة مقابل عمر الخدمة. بالنسبة للبيئات عالية التآكل، غالبًا ما يوفر أنبوب ألياف الكربون المنثورة الممتاز المال على المدى الطويل.

7: عدم مراعاة الآثار البيئية وآثار الاستدامة

يتجاهل بعض المهندسين الآثار طويلة الأجل للتخلص أو إعادة التدوير. ومع ازدياد الطلب على ألياف الكربون، تثقل الاستدامة كاهلهم. فاختيار الراتنجات القابلة لإعادة التدوير أو التصاميم الصديقة لإعادة الطحن يقلل من النفايات المستقبلية.

الحل: اسأل المورد الخاص بك عن تخطيط نهاية العمر الافتراضي. يمكن إعادة استخدام الأنبوب المستطيل المصنوع من ألياف الكربون المصنوع من راتنج اللدائن الحرارية بسهولة أكبر من الإصدارات المصنوعة من اللدائن الحرارية.

8: التغاضي عن تحديات الملاءمة والاتصال

يكمن السهو الشائع في افتراض أن أنابيب ألياف الكربون تتصل بسهولة مثل الأنابيب المعدنية. يتطلب الربط أو التثبيت أو التثبيت بالبراغي أو التثبيت اهتمامًا خاصًا. قد لا يستقر أنبوب الألياف الكربونية المربعة في الأجهزة القياسية، مما يؤدي إلى تركيز الضغط.

الحل: خطط لطرق الربط مبكرًا. التركيبات المخصصة أو المواد اللاصقة المصممة خصيصاً لأنابيب الألياف لتجنب الصداع لاحقاً.

نصائح لاختيار أنبوب ألياف الكربون بذكاء أكبر

لتجنب تكرار نفس المزالق، إليك بعض الاستراتيجيات العملية التي يمكن للمهندسين اتباعها:

طابق الهندسة مع التطبيق: استخدم الأنابيب الدائرية المصنوعة من ألياف الكربون لأعمدة الدوران، والأنابيب المستطيلة للعوارض، والأنابيب المربعة للإطارات.

ضع في اعتبارك مسارات التحميل: قد يناسب الأنبوب المصنوع من ألياف الكربون مقاس 1 بوصة الطائرات بدون طيار، بينما يدعم الأنبوب المصنوع من ألياف الكربون مقاس 4 بوصة الأنظمة الفضائية أو البحرية الكبيرة.

قوة التوازن والوزن: قارن دائمًا قوة الأنبوب المصنوع من ألياف الكربون بمتطلبات المشروع بدلاً من الاعتماد على الجدران السميكة.

طلب بيانات الاختبار: لا تعتمد فقط على ادعاءات المورد - اطلب تقارير الشد والضغط والقص.

عامل البيئة: يتطلب التعرض العالي للأشعة فوق البنفسجية أو الإعدادات البحرية طلاءات خاصة أو أنظمة راتنج.

الخاتمة

توفر تقنية أنابيب ألياف الكربون مزايا مذهلة من حيث القوة إلى الوزن، ولكن فقط عند اختيارها بحكمة. وغالبًا ما يتعثر المهندسون في عدم تطابق الألياف والراتنج، أو يتجاهلون التباين في الخواص أو يتخطون الفحص تمامًا. ومع ذلك فإن كل خطأ ينطوي على حل. من خلال التخطيط لتوجيه الألياف، والتحقق من جودة التصنيع، ومواءمة التكلفة مع أداء دورة الحياة، تحقق المشاريع المتانة والكفاءة على حد سواء. سواء أكنت تزن أنبوبًا رفيعًا من ألياف الكربون مقاس 1 بوصة للروبوتات أو أنبوبًا من ألياف الكربون شديد التحمل مقاس 4 بوصات للفضاء، فإن الاختيار المدروس يحافظ على عدم ارتكاب الأخطاء ويجعل التصاميم تحلق عاليًا.

رد واحد