Introduction to Carbon Fiber Sheet Weave Patterns

Carbon Fiber sheet design isn’t all about thickness or resin—one overlooked factor is the carbon fiber weave pattern. This pattern changes how your sheet behaves. Looks good? Sure. But strength, flexibility, weight, and price all shift with each weave. Whether you’re selecting a carbon fiber panel sheet for drones, automotive parts, or custom panels, pattern choice matters.

This guide digs into carbon fiber weave patterns, from traditional twill to high-tech braided weaves. You’ll see what makes them tick and how to choose one that fits your needs—not just looks cool on paper.

What Are Carbon Fiber Weave Patterns?

Weave patterns refer to the layout of the carbon tow bundles in a sheet. These patterns define the mechanical behavior and appearance of each carbon fiber sheet, panel, or sandwich panel.

Here’s what determines the weave:

How the tows cross (over-under, flat, diagonal)

The tightness of the weave

Direction of fibers (unidirectional or multidirectional)

Think of it like denim—tight weave, loose weave, plain, or stylish twill. All denim, but each with its flavor and function. Same deal here.

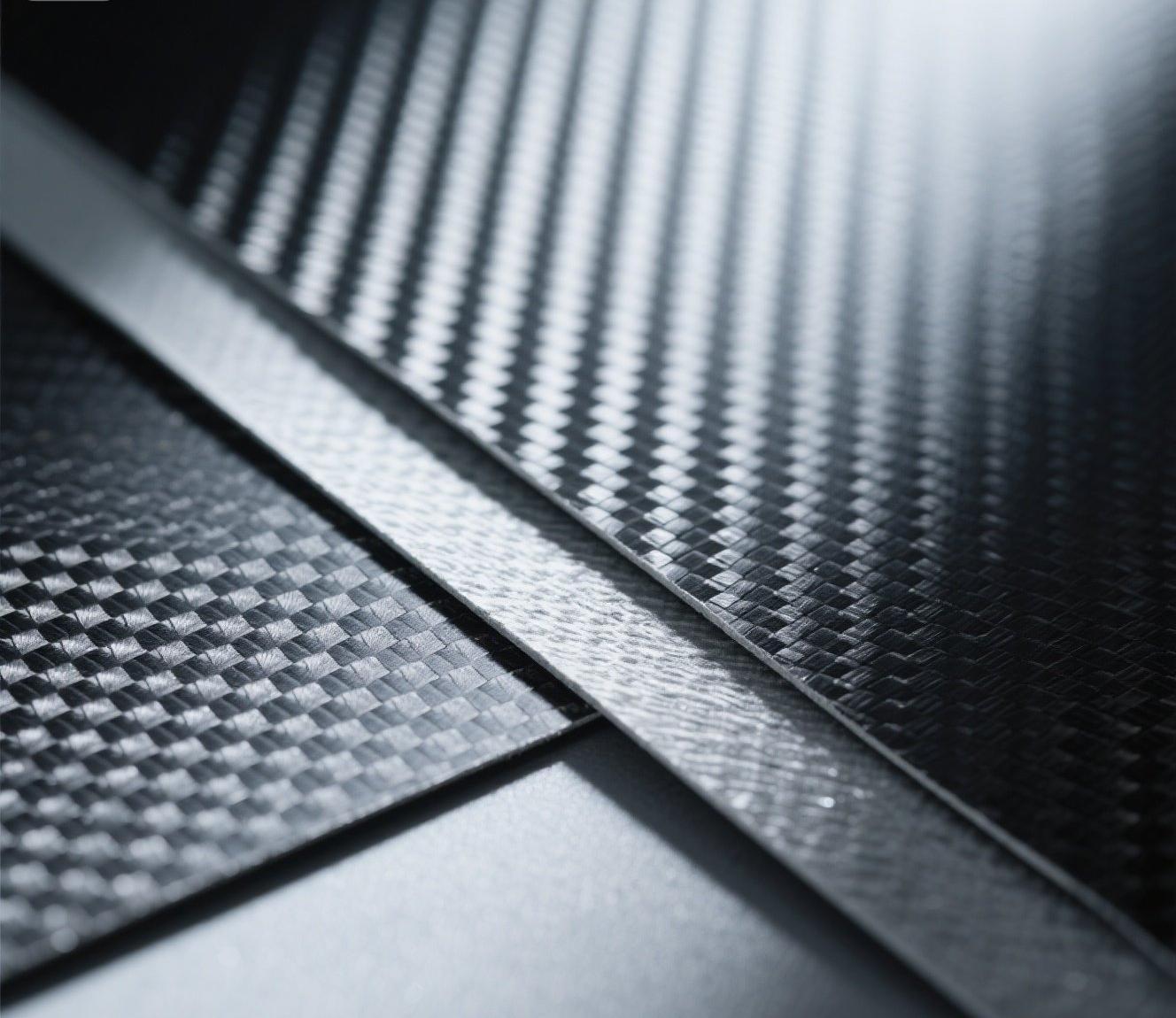

Popular Carbon Fiber Weave Patterns Explained

Let’s break down the most common carbon fiber panel sheet patterns in the market.

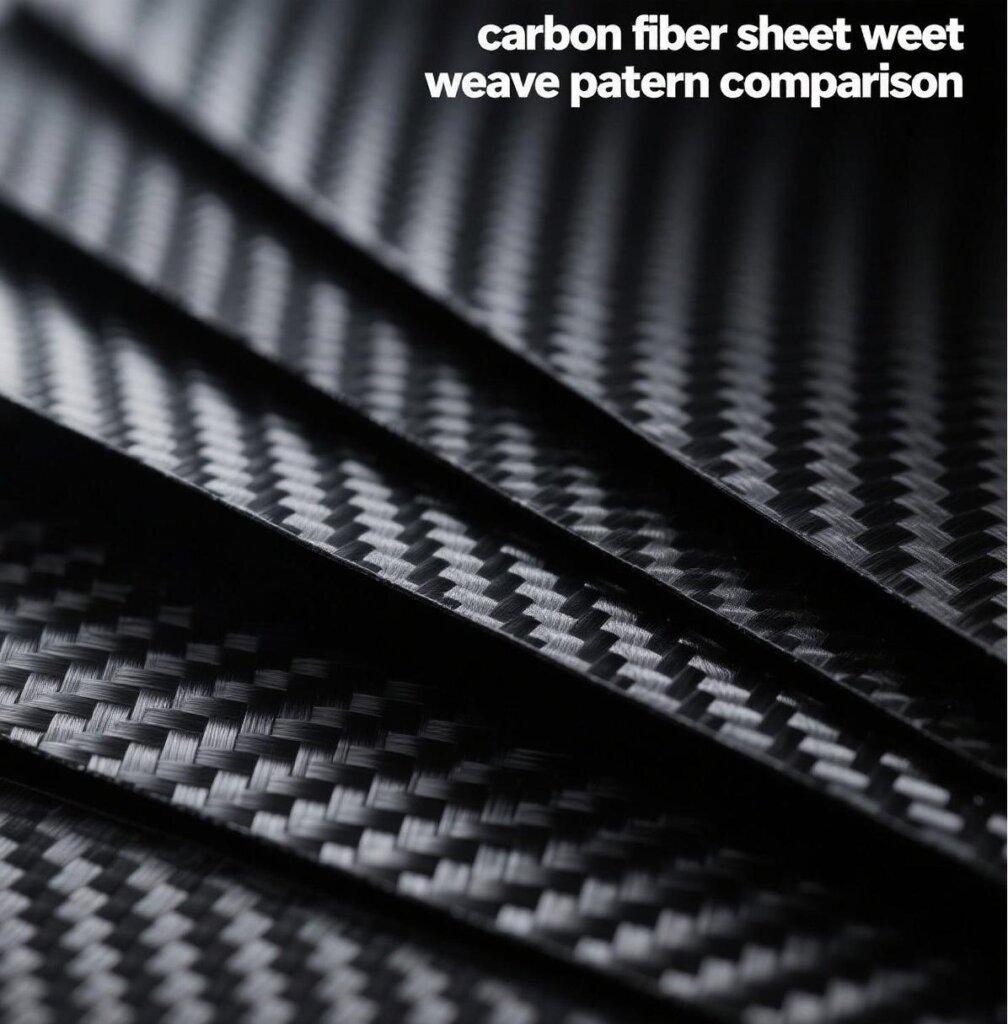

1. Plain Weave

Tight. Symmetrical. Basic. The tows go over and under each other, like a checkerboard.

Pros: Excellent stability, easy handling, strong in both directions

Cons: Less flexible, prone to fraying at cut edges

Looks: Small checkered look

Use it for carbon fiber sandwich panel surfaces, panels that need less drape.

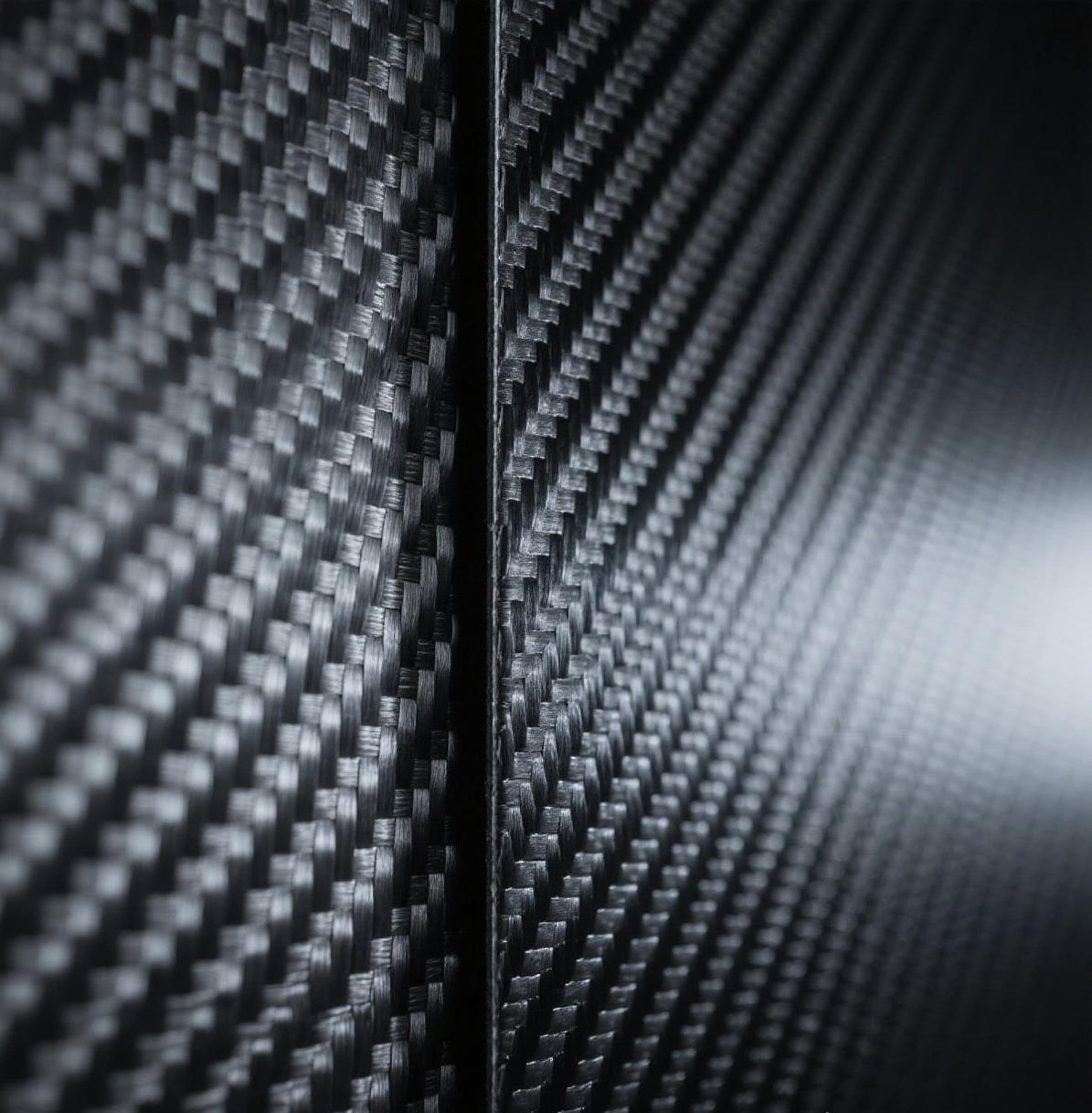

2. Twill Weave

This pattern allows tows to go over two, under one—creating a diagonal rib. Fancy stuff.

Pros: High drapeability, smoother edges, stylish finish

Cons: Slightly lower stability than plain weave

Looks: Signature 2×2 twill, that classic carbon fiber look

Perfect for visible surfaces where aesthetics count, like automotive dashboards or consumer tech.

3. Harness Satin Weave

More relaxed layout. Tows float over multiple others before diving under one.

Pros: Ultra-drapable, great for molds with complex shapes

Cons: Delicate edges, needs extra care

Looks: More flowing and less geometric

Often used in curved panels or compound shapes where molding is tricky.

4. Unidirectional (UD)

UD fabrics feature all fibers aligned in a single direction, without interlacing. This results in maximum tensile strength along the fiber axis and minimal crimp-induced weakness. UD is perfect for tailored stiffness—for example, in bike tubes and aerospace stiffeners—but requires care in handling.

Spread Tow and Braided Carbon Fiber Weave Patterns

4. Spread Tow Weave

This pattern flattens tows into ribbons. It reduces gaps between fibers, resulting in a smoother finish and less resin pooling.

Pros: Ultra-lightweight, high stiffness, lower resin use

Cons: Costly, not as impact-resistant

Looks: Modern, ultra-flat weave

Ideal for carbon fiber sheet applications where weight is a big deal—like racing or drones.

5. Braided Weave

Instead of woven flat sheets, braided weaves wrap carbon fibers around a tubular or circular shape.

Pros: Great multidirectional strength, seamless transitions

Cons: Tough to cut cleanly, less surface finish control

Looks: Diamond or spiral texture

Often found in carbon fiber honeycomb panel reinforcements or tubes.

Carbon Fiber Weave Comparison Table

| Weave Pattern | Flexibility | Strength | Visual Appeal | Ideal Use Case |

|---|---|---|---|---|

| Plain Weave | Low | High | Low | Flat panels, stable components |

| Twill Weave | Medium | High | High | Visible parts, automotive panels |

| Satin Weave | High | Medium | Medium | Molded parts, curved panels |

| Spread Tow | Medium | Very High | Very High | Aerospace panels, ultra-light gear |

| Braided Weave | Very High | High | Medium | Tubular structures, reinforcement |

Choosing the Right Carbon Fiber Sheet Weave Pattern

Picking a weave pattern ain’t random. You’ve got to match the pattern to the panel’s role.

Ask yourself:

Does it need to look sleek or work hard?

Will it face complex curves or sit flat?

Need flexibility or rigidity?

Will it be part of a carbon fiber honeycomb panel core or a plain outer sheet?

Use Case Breakdown:

Flat Sheets: Go for plain weave if you’re looking for dimensional stability.

Curved Surfaces: Satin or twill offers the flexibility required.

High-End Finishes: Twill and spread tow win on looks.

Structural Panels: Use plain or braided for strength.

Lightweight Goals: Spread tow cuts down on resin weight.

Pro Tip: Don’t just chase aesthetics. A 2×2 twill looks cool, but your panel might need strength more than shine.

Custom Carbon Fiber Panel Sheet Solutions

Sometimes the job’s weird. Odd shape. Wild load direction. In those cases, go custom.

Ask your supplier about:

Hybrid layups (combining weave types)

Co-curing with foam or honeycomb cores

Special resin systems for different temperatures

Carbon fiber sheet producers can layer different weaves together. You might start with a twill surface and bury a plain weave for strength inside. Sneaky but effective.

Wrapping It Up: Why Weave Pattern Choice Matters

You wouldn’t build a racing bike out of steel. So don’t slap the wrong weave on your carbon fiber project.

From carbon fiber sandwich panels to decorative carbon fiber panel sheets, your choice of weave determines more than how it looks. It shapes how the thing bends, reacts, and survives stress.

Stick with carbon fiber sheet suppliers who understand these patterns inside-out. They’ll save you from choosing a style that looks slick but performs like wet cardboard.