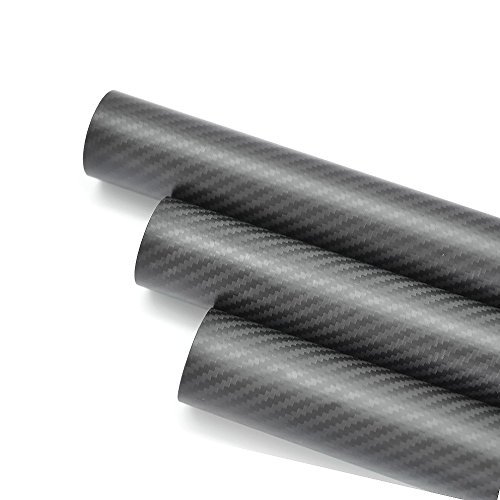

Rohre aus Kohlefaserdie wegen ihres außergewöhnlichen Verhältnisses von Festigkeit zu Gewicht und ihrer Korrosionsbeständigkeit geschätzt werden, finden breite Anwendung in der Luft- und Raumfahrt, in medizinischen Geräten, Sportausrüstungen und vielem mehr. Präzise Schnitte an Kohlefaserrohren, insbesondere zur Einhaltung strenger Toleranzanforderungen, stellen jedoch für viele Kunden eine Herausforderung dar. Dieser Artikel befasst sich mit den entscheidenden Schritten, häufigen Problemen und Lösungen für das präzise Schneiden von Kohlefaserrohren und zeigt auf, wie ein sorgfältiges Schneiden starke Kundenbeziehungen fördern kann.

Wenn Sie Folgendes brauchen Kohlefaserrohre kaufen Präzision ist wichtig. Sie verwandelt einen einfachen Kauf in eine geschätzte Partnerschaft. Viele Kunden suchen nach einer zuverlässigen Quelle für Geschäft mit Kohlefaserrohren Lösungen. Korrekte Abmessungen und glatte Oberflächen reduzieren den Abfall und steigern den Erfolg Ihres Projekts. In diesem Artikel erfahren Sie, wie Sie präzise Schnitte an Kohlefaserrohren durchführen können. Wir werden auch untersuchen, wie diese Schnitte das Vertrauen des Kunden verbessern.

Warum Präzisionsschneiden wichtig ist:

- Strenge Toleranzanforderungen erfüllen: Viele Anwendungen erfordern eine hohe Maßhaltigkeit für KohlefaserrohreJede Abweichung kann zu Montageproblemen oder Leistungseinbußen führen.

- Reduzierung von Abfall und Kosten: Präzise Schnitte minimieren den Materialabfall, senken die Produktionskosten und erhöhen die Kundenzufriedenheit.

- Kundenvertrauen aufbauen: Hochwertige und präzise Schneidedienstleistungen schaffen Vertrauen und Loyalität bei den Kunden.

- Gewährleistung der Sicherheit: Beim Schneiden von Karbonfasern entstehen Staub und Schutt, die sowohl Menschen als auch Geräte schädigen können; Präzisionsschneiden hilft, diese Risiken zu verringern.

Materialien und Werkzeuge Vorbereitung:

- Persönliche Schutzausrüstung (PSA):

- Schutzbrille: Zum Schutz der Augen vor Verunreinigungen.

- Effizientes Staubsammelsystem: Um das Einatmen von Kohlefaserstaub zu verhindern.

- Gehörschutz: Um die Auswirkungen von Lärm auf das Gehör zu minimieren.

- Schutz der Atemwege: Zum Filtern von luftgetragenen Partikeln.

- Schneidewerkzeuge:

- Diamantbeschichtete Trennschleifblätter: Zur Vermeidung von Faserausrissen und Delaminierung.

- Nassschneidesägen (optional): Zur Verringerung der Schneidewärme und zur Verhinderung des "Verklebens" von Harz.

- Finishing Tools:

- Schleifpapier oder Schleifmittel: Zum Entfernen von Graten und Fasern.

- Messgeräte:

- Messschieber oder Bügelmessschrauben: Zur genauen Messung der Schnittlänge und zur Überprüfung der Toleranzen.

- Winkellineale: Zur Gewährleistung genauer Schnittwinkel.

Präzise Schneideschritte für Kohlefaserrohre:

- Wählen Sie die richtige Klinge:

- Verwenden Sie diamantbeschichtete Schleifblätter und vermeiden Sie gezahnte Blätter, die die Fasern zerreißen.

- Bei dickwandigen Rohren sollten Sie segmentierte Klingen oder Nassschneiden in Betracht ziehen, um die Hitze zu reduzieren.

- Sichere Unterstützung:

- Verwenden Sie Klammern oder Stützen zur Stabilisierung der KohlefaserrohrDadurch wird eine Bewegung während des Schneidens verhindert.

- Verwenden Sie gerade Kanten oder Dämme, um genaue Schnittwinkel zu gewährleisten.

- Stellen Sie sicher, dass sowohl das Schnitt- als auch das Fallende des Rohrs unterstützt werden, um Grate zu vermeiden.

- Langsam schneiden:

- Vermeiden Sie übermäßigen Druck auf das Schneidemesser; lassen Sie es natürlich schneiden.

- Kontrollieren Sie die Schnittgeschwindigkeit, um das Risiko von Hitze und Delamination zu minimieren.

- Feinschliff:

- Verwenden Sie Schleifpapier oder Schleifmittel, um Grate und Fasern von der Schnittkante zu entfernen.

- Verwenden Sie feines Schleifpapier, um die Kanten zu glätten.

- Präzises Messen:

- Verwenden Sie Messschieber oder Mikrometer, um die Schnittlänge zu messen und sicherzustellen, dass sie innerhalb der vom Kunden gewünschten Toleranzen liegt.

- Prüfen Sie den Schnittwinkel mit einem Winkellineal.

Gemeinsame Probleme und Lösungen:

- Delamination:

- Ursache: Zu hohe Schnittgeschwindigkeit, ungeeignete Klinge.

- Lösung: Reduzieren Sie die Schnittgeschwindigkeit und verwenden Sie dünnere, feinere Klingen.

- Entgraten:

- Die Ursache: Unzureichende Unterstützung der Röhre.

- Lösung: Stellen Sie sicher, dass beide Rohrenden fest abgestützt sind.

- Überhitzung:

- Ursache: Übermäßige Schnittreibung, Schneiden von dickwandigen Rohren.

- Lösung: Reduzieren Sie die Schnittgeschwindigkeit, verwenden Sie Kühlmittel (Nassschnitt).

- Ausfransen:

- Ursache: Schneiden von Aramid- oder Kohlefaser/Aramid-Hybridrohren.

- Lösung: Schleifen Sie das Rohr nach dem Schneiden.

- Toleranzkontrolle:

- Ursache: Ungenaue Messungen, instabiler Schnitt.

- Lösung: Verwenden Sie Präzisionsmesswerkzeuge, um einen stabilen Schneidprozess zu gewährleisten.

Aufbau von Kundenbeziehungen:

- Bieten Sie professionelle Beratung an: Empfehlung geeigneter Schneidlösungen und Werkzeuge auf der Grundlage der Kundenanforderungen.

- Musterzuschnitte bereitstellen: Bieten Sie Musterschnitte an, bevor Sie die volle Produktion aufnehmen, um sicherzustellen, dass die Toleranzanforderungen erfüllt werden.

- Detaillierte Toleranzberichte bereitstellen: Legen Sie der Produktlieferung detaillierte Toleranzberichte bei, um die Schnittgenauigkeit nachzuweisen.

- Rechtzeitige Kommunikation: Kommunikation mit den Kunden während der gesamten Produktion, um mögliche Probleme anzusprechen.

Wie schneidet man ein Kohlefaserrohr? Lassen Sie uns über die notwendigen Materialien sprechen. Sicherheit steht an erster Stelle, also besorgen Sie sich eine persönliche Schutzausrüstung. Sie benötigen eine Schutzbrille, eine Staubabsaugung, einen Gehörschutz und eine Atemschutzmaske. Als Nächstes besorgen Sie sich ein diamantbeschichtetes Trennschleifblatt. Dieses Blatt verhindert Absplitterungen und Delaminationen. Bereiten Sie schließlich Schleifpapier oder Schleifflächen für die Endbearbeitung vor.

Schneiden Raketenrohre aus Kohlefaser oder sogar eine einfache Zigarrenrohr aus Kohlefaser erfordert eine durchdachte Vorgehensweise. Es gibt verschiedene Möglichkeiten, diese Materialien zu schneiden. Unabhängig davon, ob Sie eine Kappsäge, eine Fliesensäge oder ein handgeführtes Werkzeug verwenden, müssen Sie bestimmte Schritte befolgen.

Nach dem Schneiden beginnen die Reinigungsarbeiten. Verwenden Sie Schleifpapier oder Schleifmittel. Dadurch werden Grate und lose Fasern entfernt. Sie erhalten eine saubere Oberfläche.

Viele Kunden wenden sich an Kohlefaserrohre kaufen für verschiedene Anwendungen. Einige bauen Teleskoprohre aus Kohlefaser andere verwenden Kohlefaser-Stabrohr für Spezialgeräte. Alle diese Projekte erfordern präzise Schnitte. Daher ist die Kontrolle der Toleranzen von entscheidender Bedeutung.

Wenn Sie versuchen, einen Ort zu finden billiges Kohlefaserrohr oder benötigen spezielle Schnitte von einem kohlefaserrohr china Lieferanten denken daran, dass Präzision die Beziehungen fördert. Präzise Schnitte zeigen Engagement. Das fördert das Vertrauen. Außerdem bietet Kohlefaser-Rohrschützer oder anderem Zubehör ein umfassender Service geboten wird.

Eine gute Kommunikation schafft starke Bindungen. Erklären Sie Toleranzen und Schnittmethoden. Beantworten Sie Fragen umgehend. Bieten Sie Probeschnitte an. So können sich die Kunden ein Bild von Ihrer Arbeit machen. Liefern Sie detaillierte Berichte. Damit zeigen Sie, dass Sie die Vorgaben erfüllen.

Zusammenfassend lässt sich sagen, dass das präzise Schneiden von Kohlefaserrohren Auswirkungen auf Toleranzen und Beziehungen hat. Es geht nicht nur um die Herstellung eines Produkts. Es geht darum, Vertrauen und Zuverlässigkeit aufzubauen. Um Qualität zu finden Kohlefaser-Raketenrohr Optionen oder einem anderen Kohlefaserprodukt einen Lieferanten in Betracht ziehen, der Wert auf Genauigkeit und Kommunikation legt.

Referenzen:

1.Der Herstellungsprozess von Kohlenstofffaserrohren: Unterschiede zwischen Filament Winding und Pultrusion

2.Wie wir unserem Kunden bei der Lösung von Produktproblemen mit unseren Kohlefaserrohren geholfen haben?

3.Können Carbonfaser-Rohre in Massenproduktion hergestellt werden? Hier erfahren Sie, was Sie wissen müssen

4.Wie man die Oberflächenqualität von Kohlenstofffaserrohren mit großem Durchmesser verbessert

5.Warum ist das Kohlefaserrohr 50mm OD 47mm ID so beliebt?

22 Antworten