Die Wahl der richtigen Materialien ist für Drohnen-Enthusiasten und professionelle Konstrukteure gleichermaßen von entscheidender Bedeutung. Kohlefaser hat sich zum Goldstandard entwickelt. Aber es stellt sich eine häufige Frage: Welche Kohlenstofffasern werden typischerweise für Drohnen verwendet? Diese Erkundung bietet Lösungen. Wir werden uns mit den verschiedenen Arten von Kohlefaserplatten und ihren Anwendungen befassen. Das Verständnis dieser Optionen ermöglicht einen besseren Drohnenbau.

Viele Bauherren suchen nach robusten und dennoch leichten Lösungen. Daher ist Kohlefaser ein nahezu perfektes Material. Seine Eigenschaften sind für Anwendungen in der Luft sehr vorteilhaft. Die Leistung einer Drohne wird durch die richtige Materialauswahl erheblich verbessert. Lassen Sie uns also genauer nachforschen.

Grundlagen der Kohlenstofffaser für Drohnenanwendungen verstehen

Was genau macht Kohlefaser zu einem Champion für die Entwicklung von Drohnen? Das Verhältnis von Festigkeit zu Gewicht kann gar nicht hoch genug eingeschätzt werden. Das bedeutet, dass Drohnenrahmen unglaublich stark sein können, ohne übermäßig schwer zu sein. Außerdem bilden Kohlefaserplatten und Harz eine steife Struktur. Diese Steifigkeit trägt zur Verbesserung der Flugstabilität und Reaktionsfähigkeit bei.

Außerdem weisen Kohlenstofffasern eine hervorragende Ermüdungsfestigkeit auf. Diese Eigenschaft ist wichtig für Drohnen, die ständigen Vibrationen ausgesetzt sind. Auch seine thermische Stabilität trägt dazu bei, dass die Integrität unter verschiedenen Bedingungen erhalten bleibt. Diese Faktoren erklären zusammengenommen, warum dieses fortschrittliche Material so weit verbreitet ist. Daher bevorzugen viele Konstrukteure die Arbeit mit einem vielseitigen Kohlefaserplattenmaterial.

Referenzen:

1. Schneiden von Kohlefaserrohren: Der Schlüssel zu Toleranz und Kundenbeziehungen

2.Wie wir unserem Kunden bei der Lösung von Produktproblemen mit unseren Kohlefaserrohren geholfen haben?

3.Wie stark sind Kohlefaserplatten?

4.Wie man die Oberflächenqualität von Kohlenstofffaserrohren mit großem Durchmesser verbessert

5.Wie werden Carbonfaserplatten hergestellt?

Arten von Kohlefasergeweben: Ein Leitfaden für Drohnenkonstrukteure

Kohlenstofffasern gibt es in verschiedenen Webmustern, die sich auf ihre Eigenschaften auswirken. Leinwandbindung bietet gute Stabilität und ein einheitliches Aussehen. Die Köperbindung bietet eine bessere Anpassungsfähigkeit an komplexe Formen - eine nützliche Eigenschaft. Bei vielen Drohnenarmen und -platten werden Kohlefaserplatten in Köperbindung verwendet. Das macht sie zu einem alltäglichen Anblick.

Satinbindung bietet eine noch bessere Anpassungsfähigkeit und eine glatte Oberfläche. Sie kann jedoch weniger stabil sein als Leinwand- oder Köpergewebe. Unidirektionale Kohlenstofffasern bieten maximale Festigkeit entlang einer bestimmten Achse. Konstrukteure setzen unidirektionale Carbonfaserplatten strategisch ein. Sie verstärken oft kritische Bereiche, die eine gerichtete Steifigkeit benötigen. Um zu wissen, welche Kohlenstofffasern typischerweise für Drohnen verwendet werden, muss man die Webart kennen.

Kohlenstofffaser-Güteklassen: Das Gleichgewicht zwischen Leistung und Kosten für Ihre Drohne

Neben der Webart spielt auch die Qualität der Kohlenstofffasern eine wichtige Rolle. Standard Modulus (SM) Carbonfasern sind recht verbreitet. Sie bietet ein gutes Gleichgewicht zwischen Festigkeit, Steifigkeit und Kosten. Viele Hobby- und einige professionelle Drohnenhersteller verwenden SM-Kohlefaserplatten zum Verkauf. Diese Qualität ist weithin verfügbar.

Intermediate Modulus (IM) Carbonfasern bieten eine höhere Steifigkeit. Dies kann für leistungsstarke FPV-Racer oder größere Kameradrohnen von Vorteil sein. IM-Fasern ermöglichen leichtere Teile bei gleicher Steifigkeit. Carbonfasern mit hohem Modulus (HM) bieten eine noch höhere Steifigkeit. HM-Fasern sind jedoch spröder und deutlich teurer. Sie sind für sehr spezielle Anwendungen reserviert. Die Anforderungen Ihres Projekts sind ausschlaggebend für die Wahl der besten Qualität.

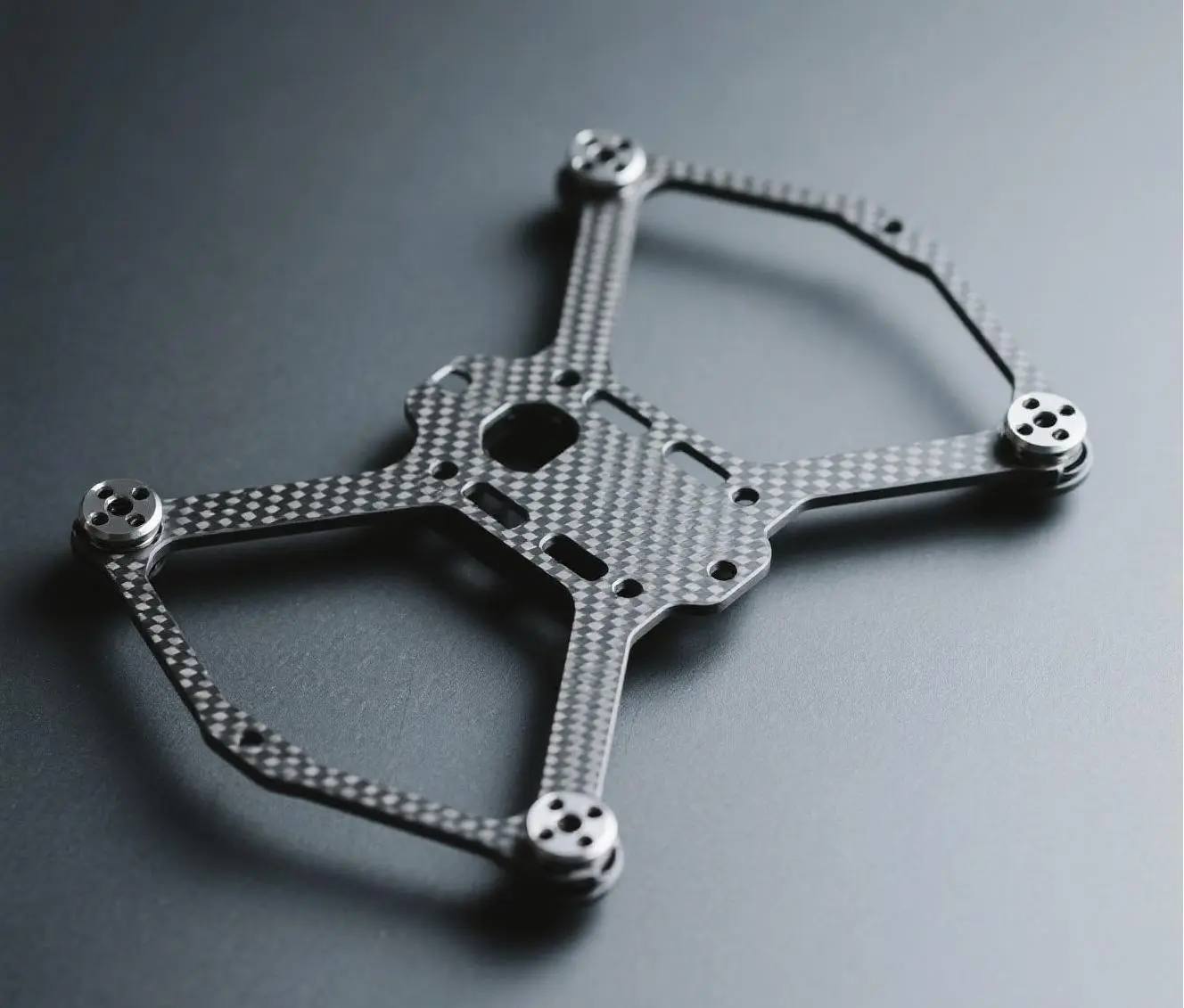

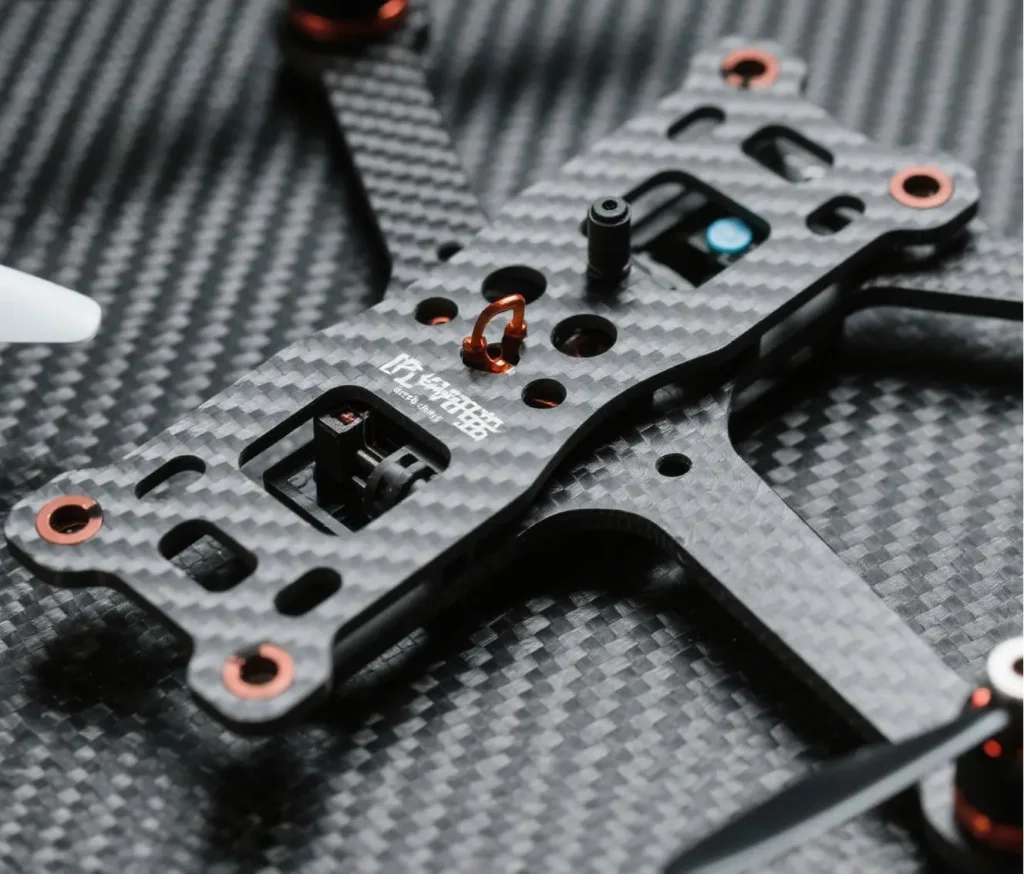

Kohlefaser-Platten: Das Rückgrat des modernen Drohnenbaus

Kohlefaserplatten sind unbestreitbar von grundlegender Bedeutung für die Herstellung von Drohnen. Diese Platten dienen als Flachmaterial, aus dem verschiedene Drohnenkomponenten geschnitten werden. Rahmenarme, Motorhalterungen und Fahrwerke werden oft aus einer Kohlefaserplatte hergestellt. Ihre gleichbleibende Dicke und Qualität sind für Präzisionsbauteile von größter Bedeutung.

Der Markt bietet Kohlefaserplatten in zahlreichen Spezifikationen zum Verkauf an. Diese Verfügbarkeit macht es für Bauherren aller Ebenen einfacher. Sie können auf hochwertige Materialien zugreifen. Sie können diese Platten bei spezialisierten Anbietern oder größeren Materialhändlern finden. Auch auf vielen Online-Plattformen ist der Kauf von Kohlefaserplatten so einfach wie nie zuvor.

Erkundung gängiger Größen: Die vielseitige 3mm Kohlefaserplatte

Eine 3 mm dicke Kohlefaserplatte ist in der Drohnenbranche äußerst beliebt. Diese Dicke bietet eine hervorragende Mischung aus Steifigkeit und angemessenem Gewicht. Für viele kleine bis mittelgroße Drohnen bieten Arme aus 3 mm Kohlefaserplatten eine ausreichende Festigkeit. Diese können Abstürze überstehen, die bei FPV-Rennen typisch sind.

Außerdem werden häufig Karosseriebleche aus dieser Abmessung hergestellt. Eine 3 mm dicke Kohlefaserplatte lässt sich mit geeigneten Werkzeugen relativ leicht schneiden und bearbeiten. Dank ihrer Vielseitigkeit können Sie einen kompletten robusten Drohnenrahmen bauen. Das macht sie zu einem Grundnahrungsmittel für viele Drohnenprojekte. Bei der Frage, welche Kohlefaser typischerweise für Drohnen verwendet wird, wird oft auf diese Stärke verwiesen.

Größere Formatoptionen: Die 4×8 Kohlefaserplatte verstehen

Für größere Projekte oder zur effizienten Herstellung mehrerer Teile ist eine 4×8-Kohlefaserplatte eine hervorragende Option. Dieses größere Format der Kohlefaserplatte 4×8 minimiert den Abfall beim Schneiden vieler Komponenten. Es ist wirtschaftlich für kleine Produktionsläufe. Größere Drohnen, wie z. B. Schwerlast-Kamerarigs, können Teile erfordern, die aus einer 4×8-Kohlefaserplatte geschnitten werden.

Die Arbeit mit Kohlefaserplatten 4×8 erfordert mehr Platz. Auch die Handhabung kann etwas mühsamer sein. Die Vorteile der Materialausbeute und die potenziellen Kosteneinsparungen pro Teil sind jedoch attraktiv. Wenn Sie große Mengen an Kohlefaserplatten benötigen, ist es sinnvoll, diese größeren Formate zu verwenden. Einige Lieferanten haben sich auf Kohlefaserplatten im Format 4×8 spezialisiert.

Beschaffung Ihrer Materialien: Wo man Kohlefaserplatten kaufen kann

Die Suche nach einer zuverlässigen Quelle für den Kauf von Kohlefaserplatten ist entscheidend. Seriöse Lieferanten gewährleisten die Qualität und Konsistenz des Materials. Achten Sie auf Anbieter, die detaillierte Spezifikationen für ihr Kohlefaserplattenmaterial bereitstellen. Dazu gehören der Gewebetyp, die verwendete Harzqualität und die Dickentoleranz. Solche Informationen helfen Ihnen bei der Auswahl der richtigen Kohlefaserplatte.

Online-Fachgeschäfte, die sich auf Verbundwerkstoffe oder Drohnenteile spezialisiert haben, sind eine gute Anlaufstelle. Sie führen oft verschiedene Größen, darunter auch die beliebten 3 mm starken Kohlefaserplatten. Für Großeinkäufe oder eine 4×8 Kohlefaserplatte bieten industrielle Verbundstofflieferanten möglicherweise bessere Preise. Vergleichen Sie immer die Optionen, bevor Sie sich entscheiden, wo Sie Kohlefaserplatten kaufen möchten. Kundenrezensionen können ebenfalls Aufschluss geben.

Die Bedeutung des Harzes bei Kohlenstofffaserplatten und Harzsystemen

Das Harzsystem in Kohlenstofffaserplatten und Harzverbundwerkstoffen spielt eine entscheidende Rolle. Epoxidharz wird am häufigsten für Kohlenstofffasern in Drohnenqualität verwendet. Es bietet im Vergleich zu anderen Harzen eine bessere Festigkeit, Haftung und Umweltbeständigkeit. Die Eigenschaften der ausgehärteten Kohlenstofffaserplatten werden durch den Harztyp erheblich beeinflusst.

Vorimprägnierte Kohlenstofffaserplatten, so genannte Prepregs, sind bereits mit Harz getränkt. Diese bieten eine bessere Qualitätskontrolle und Leistung, erfordern aber spezielle Aushärtungsprozesse. Für die meisten Heimwerker und kleinen Bauherren sind vollständig ausgehärtete Kohlefaserplatten praktischer. Diese Platten können sofort zugeschnitten und verwendet werden. Das Verständnis des Harzes hilft bei der Beantwortung der Frage, welche Kohlenstofffasern typischerweise für Drohnen verwendet werden.

Wichtige Überlegungen bei der Auswahl von Kohlenstofffasern für Ihr Drohnenprojekt

Mehrere Faktoren beeinflussen die Entscheidung, welche Karbonfasern typischerweise für Drohnen in einer bestimmten Konstruktion verwendet werden. Der Typ und die Größe Ihrer Drohne sind die wichtigsten Faktoren. Ein leichtgewichtiger FPV-Racer hat andere Anforderungen an das Material als eine große Plattform für Luftaufnahmen mit teurer Ausrüstung. Der Racer legt vielleicht mehr Wert auf die Stoßfestigkeit einer 3 mm dicken Kohlefaserplatte. Die Kameradrohne benötigt vielleicht die ultimative Steifigkeit eines dickeren oder höherwertigen Kohlefaserplattenmaterials.

Auch Ihr Budget spielt bei der Auswahl eine Rolle. Fasern mit höherem Modul und dickere Kohlefaserplatten kosten im Allgemeinen mehr. Es ist eine praktische Notwendigkeit, die gewünschte Leistung mit den verfügbaren Mitteln in Einklang zu bringen. Außerdem kommt es auf Ihre Fähigkeiten und die verfügbaren Werkzeuge für die Bearbeitung einer Kohlefaserplatte an. Einige Materialien sind leichter zu verarbeiten als andere. Denken Sie über diese Aspekte sorgfältig nach.

Arbeiten mit Kohlefaserplatten: Tipps und Tricks

Die Bearbeitung von Kohlefaserplatten erfordert einige spezielle Techniken. Zum Schneiden einer Kohlefaserplatte eignet sich ein Dremel mit einer Diamanttrennscheibe oder einem fein gezahnten Hartmetallsägeblatt. Zum Bohren von Löchern werden scharfe Hartmetallbohrer benötigt. Gehen Sie langsam vor, um eine Delaminierung oder Absplitterung zu vermeiden. Dies gewährleistet saubere Ergebnisse.

Tragen Sie unbedingt immer eine geeignete persönliche Schutzausrüstung (PSA). Kohlefaserstaub reizt die Atemwege und kann Hautreizungen verursachen. Eine Atemschutzmaske N95 oder besser Handschuhe und eine Schutzbrille sind unerlässlich. Arbeiten Sie in einem gut belüfteten Bereich oder verwenden Sie eine Staubabsaugung. Das Nachbearbeiten der Kanten mit feinem Schleifpapier kann ein professionelles Aussehen verleihen und Delamination verhindern.

Die Kundenperspektive: Herausforderungen im Drohnenbau mit der richtigen Kohlefaser lösen

Vom Standpunkt des Kunden aus gesehen löst die Wahl von Kohlefaser viele Probleme beim Bau von Drohnen. Langlebigkeit ist vor allem für Anfänger oder FPV-Piloten ein wichtiges Thema. Die Wahl eines robusten Kohlefaserplattenmaterials, wie z.B. einer hochwertigen 3mm Kohlefaserplatte, kann die Widerstandsfähigkeit bei einem Unfall erheblich verbessern. Dadurch werden Reparaturkosten und Ausfallzeiten reduziert. Viele suchen nach Kohlefaserplatten, die diese Widerstandsfähigkeit bieten.

Die Wahl des Materials hängt auch von der Erzielung bestimmter Flugeigenschaften ab. Wenn sich eine Drohne zu flexibel oder wackelig anfühlt, könnte ein Upgrade auf eine steifere Kohlefaserplatte oder eine andere Webart die Lösung sein. Kunden wollen eine vorhersehbare Leistung. Wenn sie Kohlefaserplatten kaufen, erwarten sie eine gleichbleibende Qualität. Das Ziel ist eine zuverlässige Plattform. Das bedeutet, dass man verstehen muss, welche Karbonfasern typischerweise für Drohnen verwendet werden und warum.

Außerdem sind Zugänglichkeit und Kosten wichtig. Die Verfügbarkeit verschiedener Carbonfaserplatten, einschließlich 4×8 Carbonfaserplatten, ermöglicht es Bauherren, Projekte zu skalieren. Ein gemeinsames Ziel ist es, erschwingliche Carbonfaserplatten zu finden, ohne dabei auf wesentliche Eigenschaften verzichten zu müssen. Informationen über Carbonfaserplatten und -harze helfen den Nutzern zu verstehen, was sie kaufen.

Zukünftige Trends bei Kohlenstofffasern für Drohnen

Die Welt der Verbundwerkstoffe entwickelt sich ständig weiter. Möglicherweise werden neue Fasertypen oder Harzsysteme in Drohnenanwendungen zum Einsatz kommen. Diese könnten ein noch besseres Verhältnis zwischen Festigkeit und Gewicht oder eine höhere Stoßfestigkeit bieten. Vielleicht werden auch nachhaltigere Produktionsmethoden für Kohlenstofffasern entwickelt. Dies könnte sich darauf auswirken, welche Kohlenstofffasern in den kommenden Jahren typischerweise für Drohnen verwendet werden.

Auch fortgeschrittene Fertigungstechniken unter Verwendung von Kohlenstofffaserplatten könnten leichter zugänglich werden. Automatisierte Schneide- und Legeverfahren könnten aus industriellen Anwendungen nach unten durchsickern. Dies könnte zu komplexeren und optimierten Drohnenkonstruktionen führen. Im Moment bietet die Vielseitigkeit der derzeitigen Materialoptionen für Kohlefaserplatten reichlich Raum für Innovationen. Die Nachfrage nach Hochleistungs-Kohlenstofffaserplatten zum Verkauf wird wahrscheinlich weiter steigen.

Schlussfolgerung: Ihr ideales Drohnenmaterial erwartet Sie

Abschließend lässt sich sagen, dass die Auswahl der für Drohnen verwendeten Kohlefaser stark von den spezifischen Projektanforderungen abhängt. Es gibt keinen einzelnen "besten" Typ. Stattdessen wählen die Konstrukteure je nach Größe der Drohne, der gewünschten Leistung, dem Budget und den Fertigungsmöglichkeiten. Das Arbeitspferd, die 3 mm dicke Kohlefaserplatte, ist nach wie vor eine sehr beliebte Wahl. Aufgrund der Ausgewogenheit ihrer Eigenschaften eignet sie sich für eine Vielzahl von Drohnenrahmen.

Für größere Operationen oder die Verschachtelung bestimmter Teile bietet eine 4×8 Kohlenstofffaserplatte Effizienz. Die Kenntnis von Bindungen wie Köper und Glattgewebe sowie von Qualitäten wie dem Standardmodulus ist entscheidend. Achten Sie beim Kauf von Kohlefaserplatten auf die Quelle und stellen Sie sicher, dass Sie hochwertiges Kohlefaserplattenmaterial erhalten. Letztendlich wird eine informierte Entscheidung über Kohlefaserplatten und Harz zu einem überlegenen Fluggerät führen. Viel Spaß beim Bauen!

8 Antworten