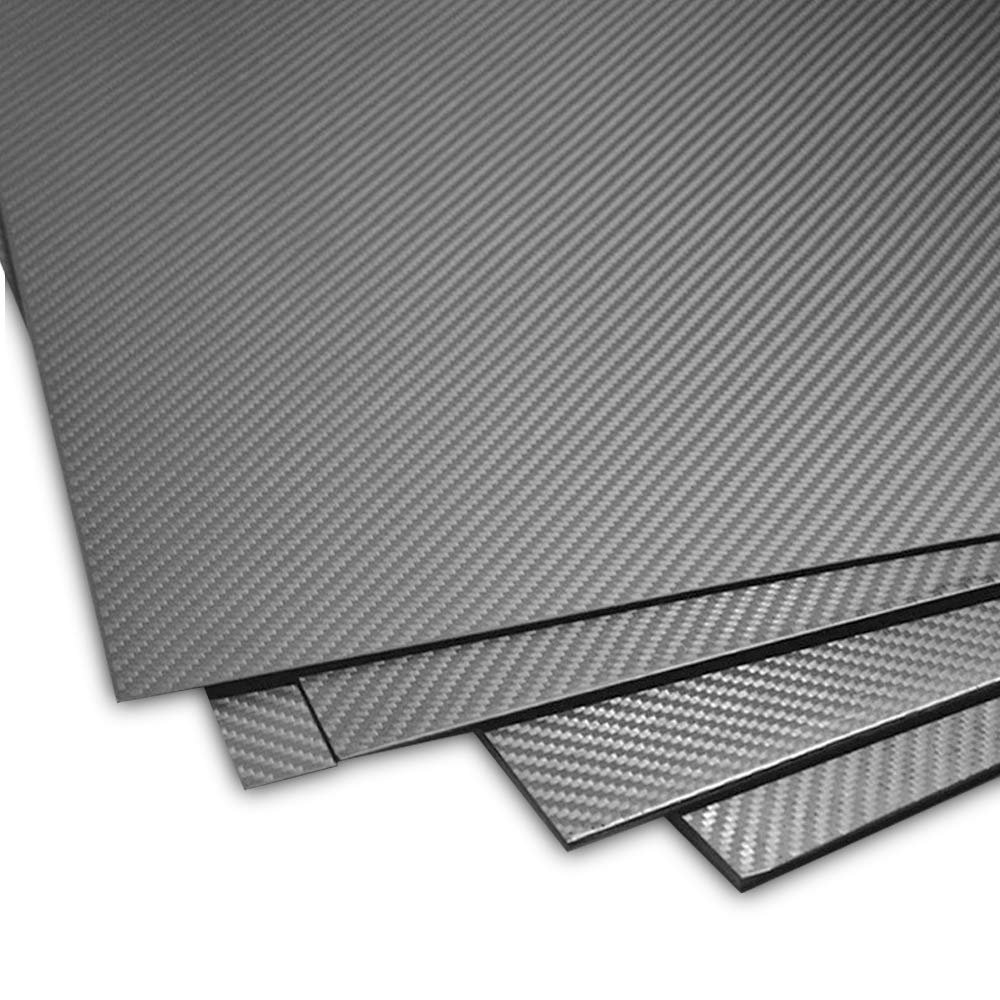

Láminas de fibra de carbono (venta de planchas de fibra de carbono) se utilizan ampliamente en los sectores aeroespacial, automovilístico y deportivo debido a su ligereza, alta resistencia y durabilidad. Tanto si se trata de un Lámina de fibra de carbono de 3 mm o un estándar 4×8 hoja de fibra de carbonoSu proceso de fabricación se controla con precisión. Este artículo explica la producción de planchas de fibra de carbono y responde a preguntas comunes como cómo cortar planchas de fibra de carbono y dónde puedo comprar planchas de fibra de carbono.

Método 1: Proceso de fabricación de las planchas de fibra de carbono

1. Preparación del precursor

El proceso comienza con un precursor (por ejemplo, poliacrilonitrilo PAN), que se carboniza para formar fibras de carbono.

2. Alineación de la fibra

Las fibras se alinean mediante pultrusión para garantizar la material de lámina de fibra de carbono tiene una gran resistencia.

3. Tejido de fibra de carbono

Las fibras se tejen en tela (láminas de fibra de carbono) y termofijar para obtener una superficie lisa.

4. Impregnación de resina

El tejido se combina con resina (láminas de fibra de carbono y resina) para aumentar la rigidez y la durabilidad.

5. Curado bajo calor y presión

Por último, las planchas se curan a alta presión, formando productos como plancha de fibra de carbono 4×8que puede cortarse a medida.

Método 2: Tratamiento y aplicaciones

1. Producción de fibra de carbono

Las materias primas se estiran bajo calor para formar fibras de carbono, la base de hoja de fibra de carbono.

2. Mezcla y moldeo de resinas

Las fibras de carbono se mezclan con resina y se prensan en moldes para crear tamaños estándar como 4×8 hoja de fibra de carbono.

3. Tratamiento de superficies

Las planchas pueden recubrirse para protegerlas contra el agua o los arañazos, según las necesidades de la aplicación.

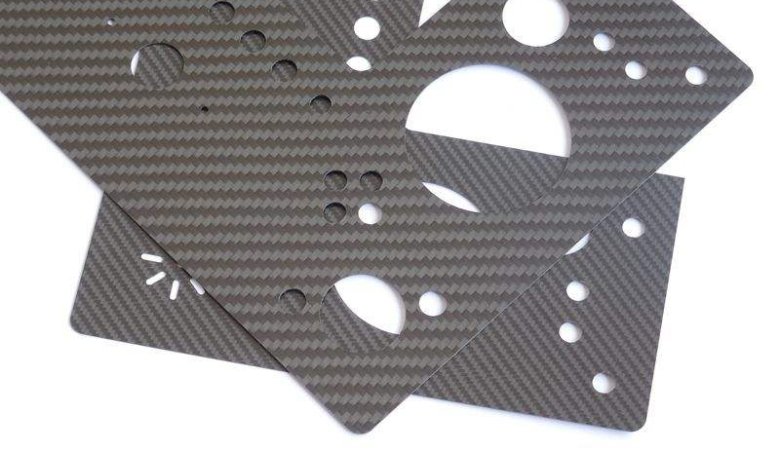

4. Corte y acabado

Las planchas curadas pueden cortarse (cómo cortar planchas de fibra de carbono) para diversos usos industriales o de bricolaje.

¿Dónde comprar planchas de fibra de carbono?

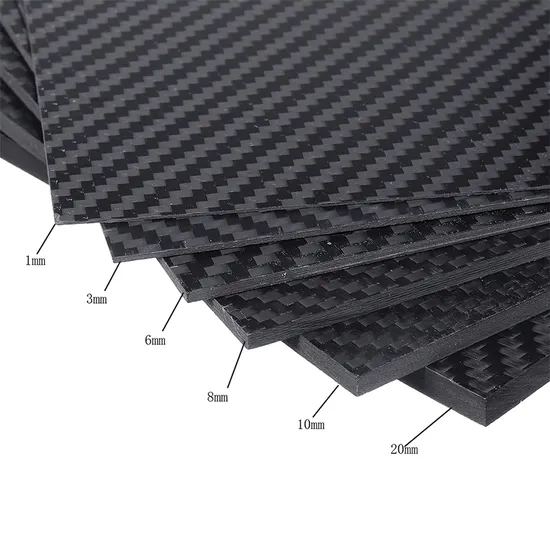

Si desea comprar planchas de fibra de carbonoSi lo prefiere, consulte a proveedores especializados en compuestos o tiendas en línea (por ejemplo, los sitios web de los fabricantes). Las opciones más comunes son Lámina de fibra de carbono de 3 mm y planchas de fibra de carbono 4×8, adecuada para la industria, el bricolaje y la fabricación de productos de gama alta.

Principales conclusiones:

✔ Fabricado con fibras de plástico calentadas

✔ La resina añade resistencia y rigidez

✔ Disponible en tamaños como 3 mm y 4×8

✔ Fácil de cortar y personalizar

Referencias:

1.¿Qué resistencia tienen las placas de fibra de carbono?

2.¿Cómo elegir la plancha de fibra de carbono adecuada para su proyecto?

3.Uso de varillas y tubos de fibra de carbono en la tecnología de drones

4.¿Cómo elegir planchas de fibra de carbono para drones?

5.¿Cuál es la diferencia entre planchas y placas de fibra de carbono?

Un comentario