Introduction: Choosing the Right Carbon Fiber Board Matters

Choosing a carbon fiber board without knowing its build is like grabbing a random battery and hoping it fits. Prepreg and laminated boards may look similar on paper, but their performance, durability, and cost vary wildly. Some boards handle stress like champs. Others exist purely for looks. One’s made with heat and pressure, the other with layers and glue.

Let’s untangle the confusion and break down both types. This guide helps you pick the board that won’t let your project fall apart.

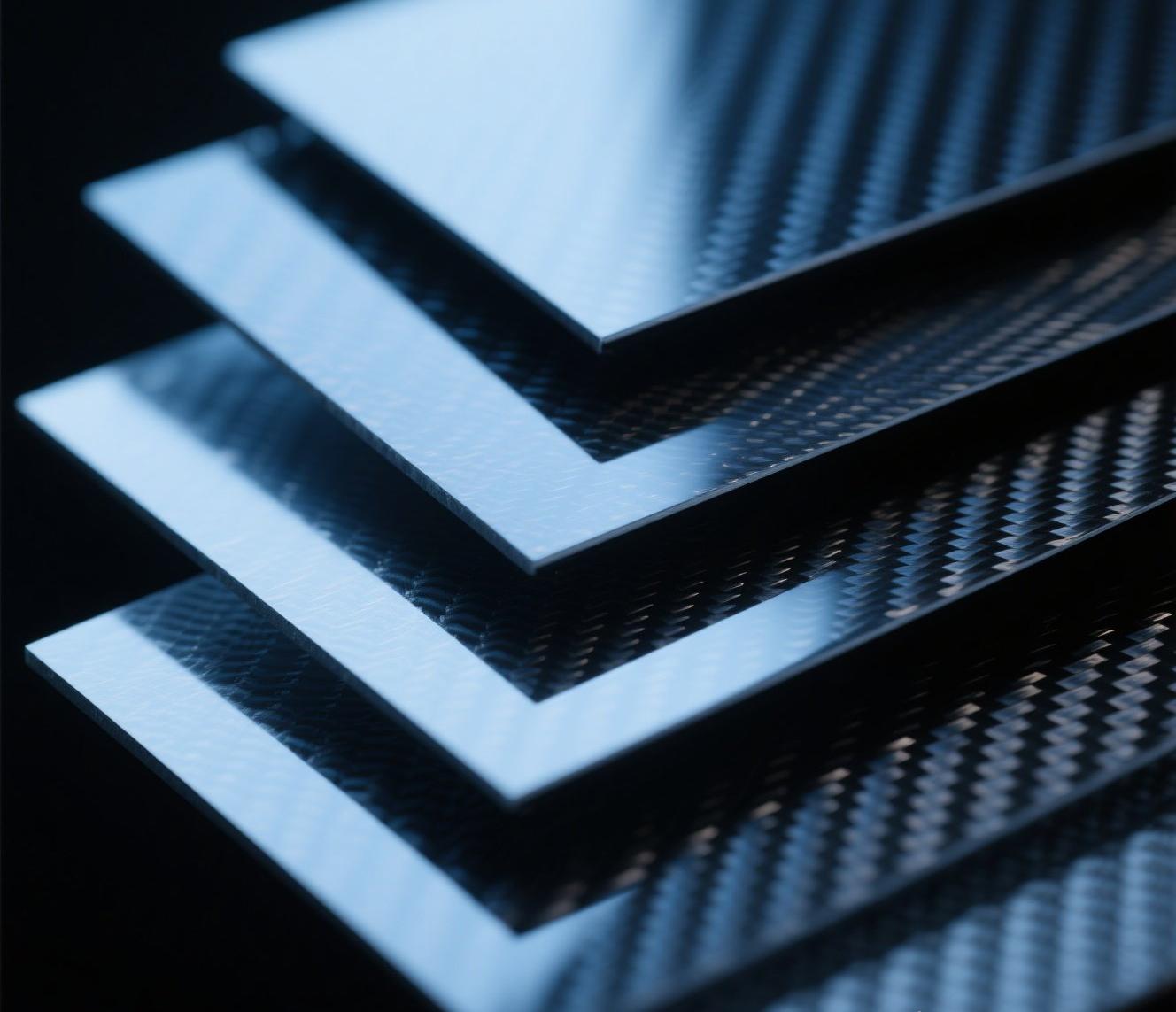

Types of Carbon Fiber Sheets Used in Boards

Whether laminated or prepreg, all boards begin with carbon fiber sheets. But different styles mean different behaviors.

Plain Weave Sheets – Basic checkerboard pattern. Stable but stiff.

Twill Weave Sheets – Diagonal flow. Flexible and smooth.

Spread Tow Sheets – Thin, flat, lightweight.

Unidirectional Sheets – All fibers run one way. Great for high-load parts.

These carbon fiber sheets get layered and bonded to form either a carbon fiber panel or a structural carbon fiber board.

What Are Carbon Fiber Sheet Types?

There are two dominant styles of carbon fiber board used in industries ranging from RC to aerospace.

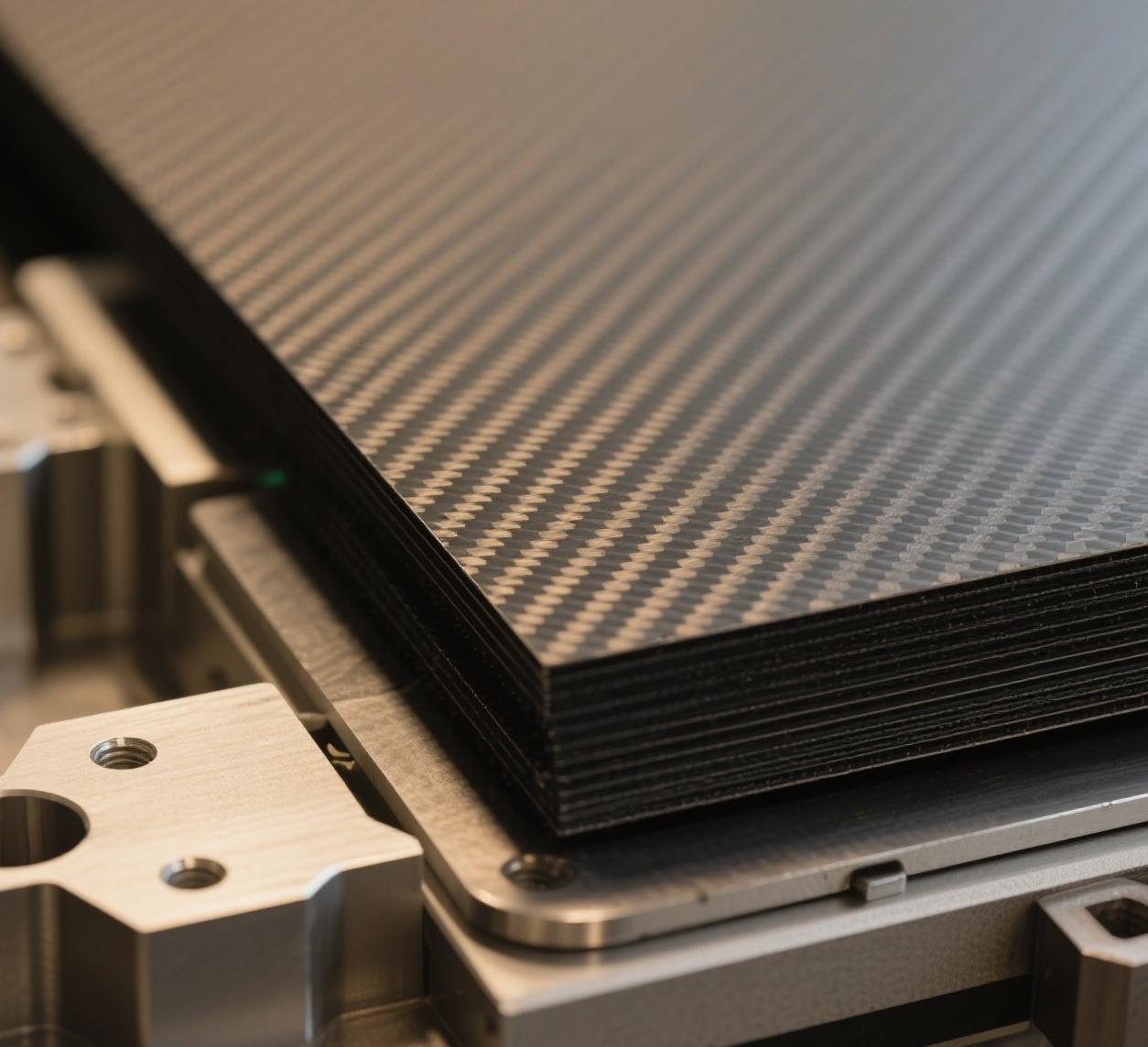

1. Prepreg Carbon Fiber Board

Prepreg stands for “pre-impregnated.” The fabric comes soaked with partially cured resin straight from the factory. It’s laid into molds then baked under pressure in an autoclave or press oven.

Controlled resin content

No messy hand layups

Excellent fiber-to-resin ratio

Ultra-consistent quality

Prepreg carbon fiber plates shine in aerospace builds, performance drones, and any situation where strength trumps looks.

2. Laminated Carbon Fiber Board

Laminated boards come from layered carbon fiber sheets and epoxy resin. The sheets get stacked, pressed flat, then cured without an autoclave.

Lower cost

Wider variety of finishes

Easier to customize or mass-produce

Can be handmade or machine layered

Perfect for decorative carbon fiber panel sheet projects or parts needing simple structure and slick visuals.

Cost & Resource Requirements

Money talks. And for many customers, it screams.

Prepreg carbon fiber board = high-end cost, high performance

Laminated carbon fiber panel = budget-friendly, faster turnaround

Prepreg boards require advanced gear: clean rooms, ovens, vacuum tools. Laminated plates? Easier to make in standard workshops.

If you need 1-2 panels for display? Laminated’s cheaper. For load-bearing arms on a racing drone? Prepreg or nothing.

Structural vs Cosmetic Carbon Fiber Board

Here’s a rule of thumb:

If it holds weight, go prepreg.

If it looks pretty, laminated works.

Prepreg boards handle torque, impact, stress, and long-term fatigue. Laminated boards handle surface gloss and moderate tension but may crack under heavy strain.

Carbon Fiber Panel Comparison: Prepreg vs Laminated

1. Strength & Performance

Prepreg wins every time. The heat-cured process aligns fibers tighter and controls resin perfectly. You get less void space and more fiber strength per mm.

Prepreg board = higher tensile strength

Laminated board = lower stiffness, more resin

If your design needs to carry weight or survive impact, prepreg’s the boss.

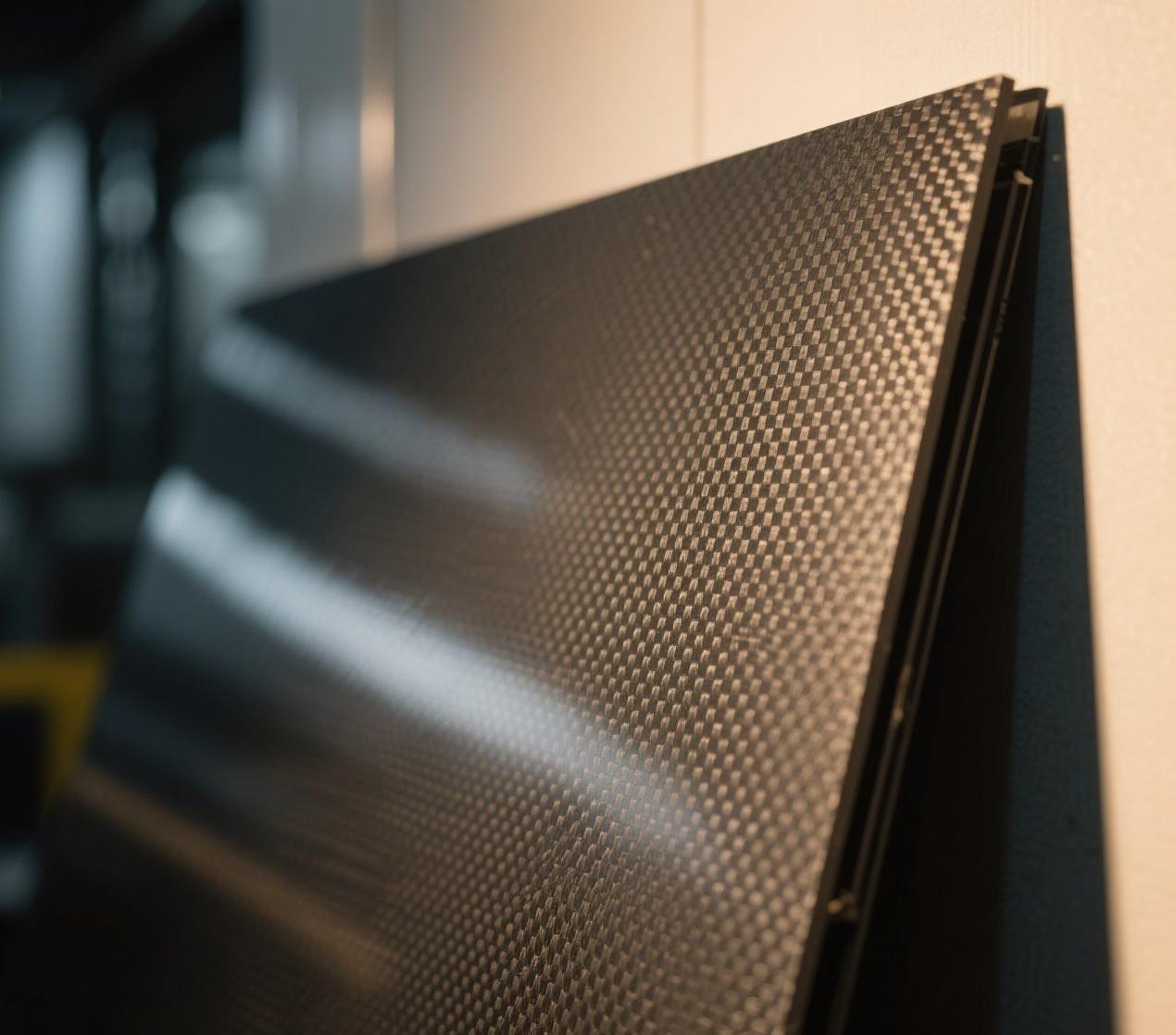

2. Surface Finish

Here’s where laminated boards sometimes score better. They often come with glossy tops or textured finishes. Laminated carbon fiber panel sheet options offer more cosmetics.

Prepreg = clean, functional, semi-gloss

Laminated = fancy topcoats, customizable faces

For visible trim, dashboards, or gadgets, laminated sheets win on style.

3. Resin Control

Prepreg’s resin is baked in by the factory. That means you don’t overdo it. No soggy spots. No dry zones.

Laminated boards rely on hand layering or pressing. That means skill levels affect the final result. Too much resin leads to weight. Too little? Weak bonds.

Manufacturing Workflow: Autoclave vs Hand-Layup

Prepreg Board Workflow

Sheets arrive resin-ready

Workers lay them in molds

Mold goes inside an autoclave or hot press

Resin cures under heat and compression

Result: high-fiber-density, structural-grade carbon fiber board

Laminated Carbon Fiber Plate Process

Raw sheets layered manually

Resin gets brushed or sprayed

Vacuum bagging or hydraulic press squeezes layers

Cures under room or oven heat

Result: decent strength, faster production, wider looks

Carbon Fiber Plates and Panel Sheets in Context

Whether used as full carbon fiber plates, thin decorative carbon fiber panel sheets, or hybrid carbon fiber panel assemblies, the core difference lies in how they’re made and how they’re meant to be used.

Laminated boards: best for quick use, good looks

Prepreg boards: best for lasting performance, high strength

Some applications blend both—prepreg core with laminated skin. If you’re ever stuck deciding, ask about how the boards were cured and what resin they used.

When to Choose Each Carbon Fiber Board Type

| Use Case | Go Prepreg | Choose Laminated |

|---|---|---|

| Racing drone frames | ✅ | ❌ |

| Decorative panels | ❌ | ✅ |

| Aerospace components | ✅ | ❌ |

| Desktop accessories | ❌ | ✅ |

| Load-bearing robotic arms | ✅ | ❌ |

| Interior trim (non-structural) | ❌ | ✅ |

Final Thoughts: Carbon Fiber Board Showdown

Both prepreg and laminated carbon fiber board options serve specific purposes. Don’t let a pretty weave fool you into choosing the wrong type. Evaluate your needs. Ask if your panel must survive hard loads or just shine under LED lights.

Use carbon fiber sheet suppliers that give technical specs up front. If they can’t say how it’s cured or what resins are involved? Move on.

Bottom line: for serious function, prepreg’s your move. For display, laminated works fine.