Table of Contents

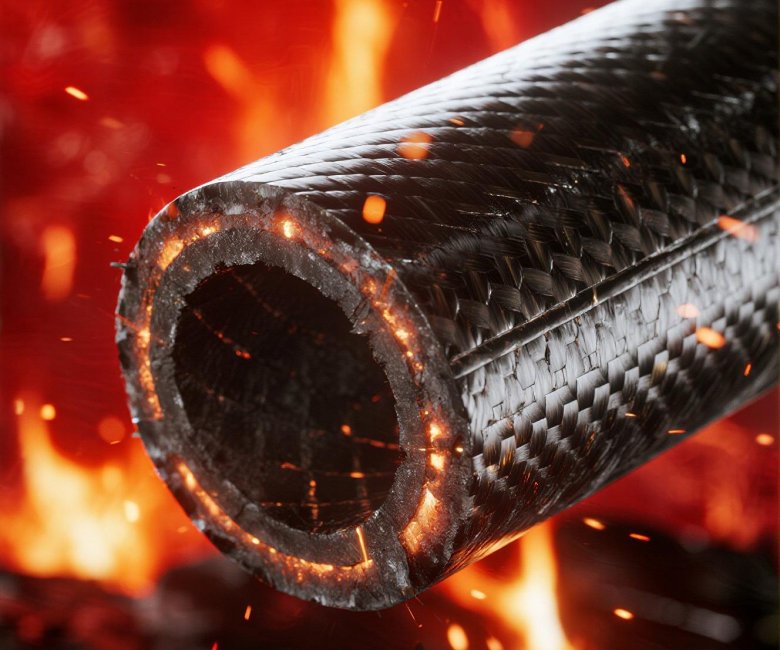

Carbon Fiber Buffer Tube: Engineered to Withstand Fire

Shooters, gunsmiths, and aerospace technicians often ask — can a carbon fiber buffer tube burn under heat? The short answer: not easily. Unlike traditional metals or plastics, this advanced carbon fiber composite tube resists extreme temperatures with remarkable stability. That’s why carbon fiber tube inserts and forged carbon fiber tubes are found in rifles, racing, and even spacecraft.

While other materials deform or fail, a custom carbon fiber tube keeps its shape. Let’s break down why this happens and what science hides behind that fireproof reputation.

Carbon Fiber’s Composition and Structure: Why Heat Fails to Beat It

The core reason a carbon fiber tube doesn’t ignite lies in its atomic arrangement. Carbon atoms bond in a tight, crystalline lattice, forming strands thinner than a human hair. Thousands of these strands twist into tows, which are later set into epoxy — creating the carbon fiber composite tube we use today.

Unlike metals that conduct heat fast, carbon fiber’s structure slows thermal transfer. Even when it’s in direct contact with flame, the surface chars while the inside stays cool. The resin might scorch, but the carbon fiber skeleton remains solid. That’s why carbon fiber pultruded rolling tubes outlast aluminum in high-heat weapon platforms.

Thermal Behavior of Carbon Fiber Composite Tube

Carbon fiber doesn’t burn in the way flammable materials do. Instead, it oxidizes slowly at extreme temperatures, usually above 650°C (1200°F). Standard operating heat in rifles or aerospace components won’t reach this threshold.

Here’s what happens when heat strikes:

The polymer resin begins to degrade near 300°C.

The carbon strands resist ignition until over 600°C.

No dripping, warping, or sudden failure occurs.

This resistance makes carbon fiber tube inserts ideal for firearm buffer systems and brake ducts in racing vehicles. Compared to plastics or even some lightweight metals, this material survives harsh thermal shock with barely a hiccup.

How Carbon Fiber Buffer Tube Reacts to Extreme Heat

Set a carbon fiber buffer tube near an open flame, and you’ll see a blackened surface but no collapse. Why? Because heat alters the surface but doesn’t consume the internal carbon strands quickly.

The epoxy might blister, and surface coatings may fade. Yet inside, the structure stays locked. There’s no melting like plastic or softening like aluminum. Instead, there’s gradual oxidation. In field testing, buffer tubes made from forged carbon fiber tube sections remained rigid even after repeated exposure to muzzle blast.

This explains why carbon fiber bent tube models are now favored in both civilian AR platforms and military-grade applications.

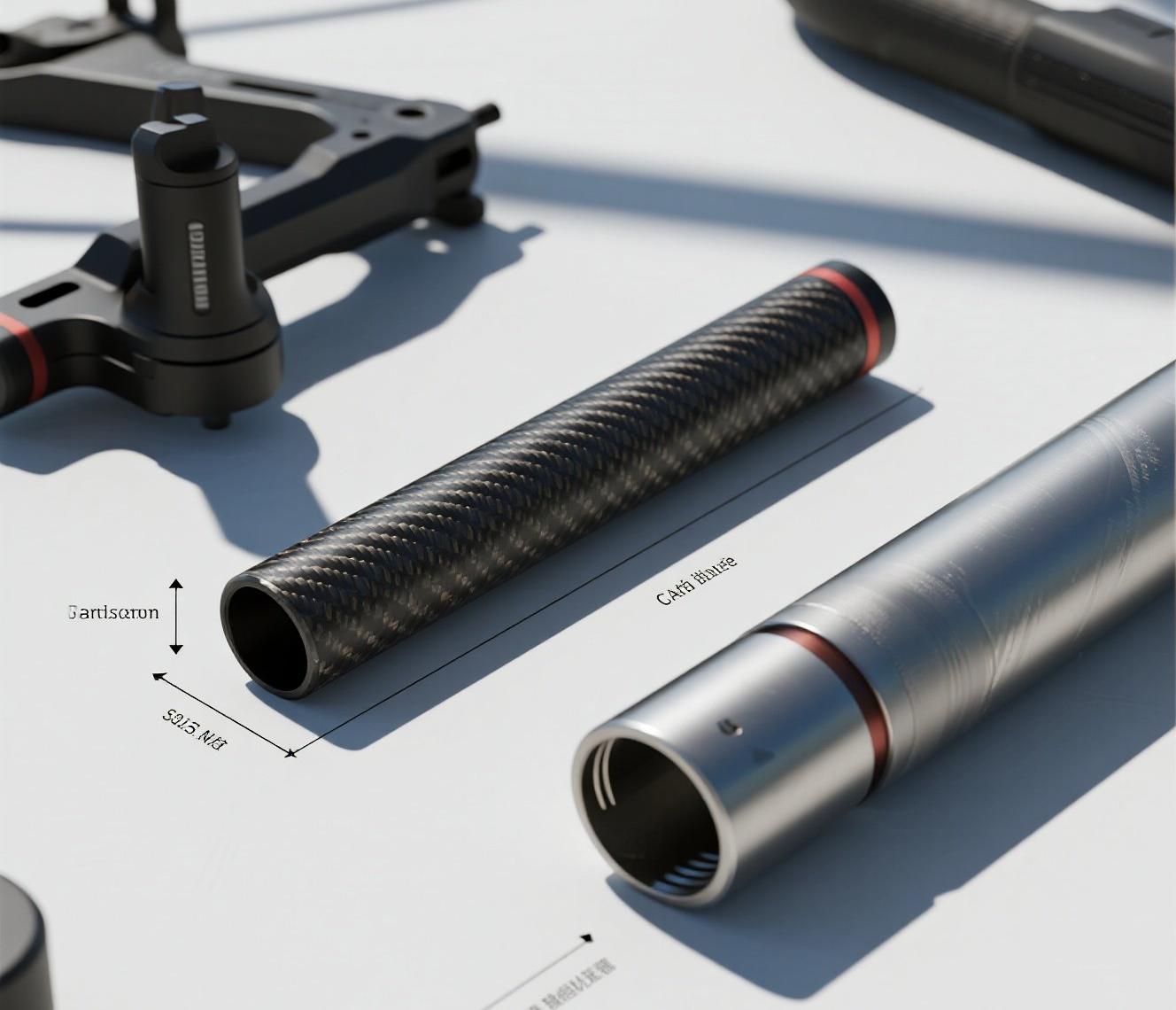

Comparison: Carbon Fiber vs. Aluminum and Polymer Tubes

Materials compete. Customers compare. So how does a carbon fiber buffer tube measure up to aluminum or polymer?

| Feature | Carbon Fiber Buffer Tube | Aluminum Tube | Polymer Tube |

|---|---|---|---|

| Weight | Ultra-light | Light | Very light |

| Heat Resistance | Excellent | Moderate | Poor |

| Stiffness | High | Medium | Low |

| Burn Risk | Very low | None (but softens) | High |

Aluminum conducts heat rapidly. Under rapid fire, it heats up fast and can become uncomfortable or unsafe. Polymer melts. But a carbon fiber composite tube stays cooler and maintains integrity.

For users who demand durability, thermal stability, and less weight, switching to a carbon fiber buffer tube is a smart move.

Real-World Uses: Why Heat Resistance Matters

This isn’t science fiction — it’s battlefield-tested. Carbon fiber buffer tubes are chosen by professionals and enthusiasts who rely on equipment under extreme stress.

Applications where fire resistance shines:

Firearm platforms: After hundreds of rounds, heat builds fast. A carbon fiber buffer tube remains unaffected.

Carbon fiber tube Canada military gear: Used in northern cold and desert heat alike.

Aviation: Carbon fiber pultruded rolling tube assemblies stay rigid near hot engine components.

RC jet turbines and drones: Carbon fiber mini tubes resist burnout in tight, hot spaces.

Every shooter or engineer who’s swapped metal for carbon finds more reliability where it counts — when things get hot.

The Future of Fire-Resistant Carbon Fiber Tube Technology

Advanced carbon fiber tech isn’t slowing down. Hybrid resins now offer better heat performance. Custom carbon fiber tube configurations allow higher load capacity while maintaining thermal resistance. Even low-cost carbon fiber tube price options are catching up with premium versions.

Soon, we may see smart carbon fiber that adjusts to heat in real time or self-healing coatings that fix surface char. Firearms and aerospace will benefit most, but racing, robotics, and even home defense setups could take advantage.

Forged carbon fiber tube upgrades may soon become a norm — not a luxury.

Buyer Tips: Choosing a Heat-Resistant Carbon Fiber Tube

Before buying, ask:

Is it made with aerospace-grade resin?

Is it a carbon fiber bent tube or pultruded type?

Is the carbon fiber tube Canada certified?

Does it include carbon fiber tube inserts for better fitting?

Always review the carbon fiber tube price vs. performance ratio. Cheap might melt. Smart buyers choose tested products that resist heat — and keep their weapon stable after 1,000 rounds.

Conclusion: Carbon Fiber Buffer Tube Won’t Burn — That’s Science

There’s a reason why shooters, engineers, and pilots trust carbon fiber buffer tubes. It isn’t just the sleek look or the light feel. It’s the science. From the molecular matrix to the fireproof edge, this gear holds up.

So whether you’re considering a forged carbon fiber tube or a carbon fiber bent tube build, heat resistance isn’t a bonus. It’s the reason to choose carbon fiber in the first place.