The Carbon Fiber Conundrum: Unpacking a Material’s Realities

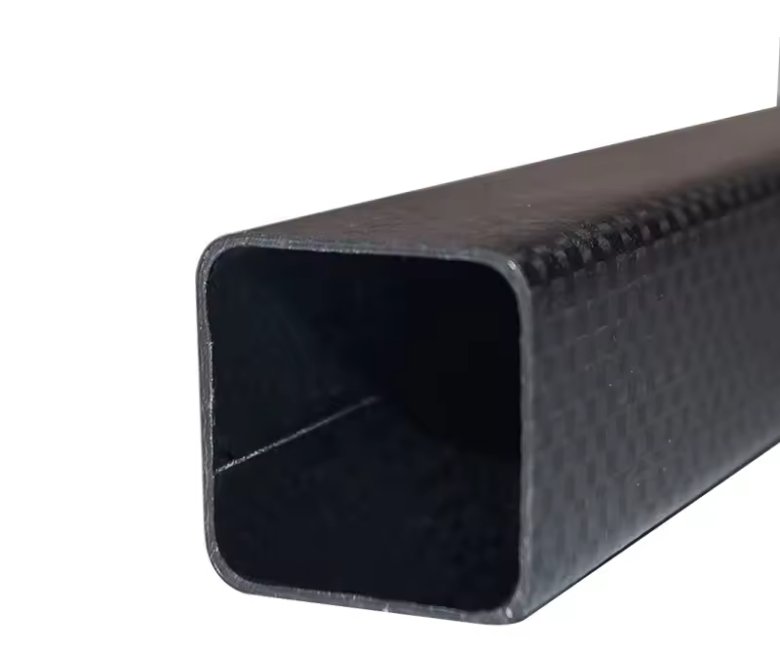

Everyone dreams of lighter stronger things. Carbon fiber seems like a magic material able to do just that. You see it in race cars and fancy bikes, yet your car isn’t made of it. Why not? Many believe carbon fiber will replace everything but that’s a myth. It holds immense promise yet faces stiff challenges. A carbon fiber square tube demonstrates exceptional strength yet broader adoption has hurdles.

The Myth of Carbon Fiber as a “Super Material”

Many folks picture carbon fiber as an indestructible wonder. They imagine a substance that can’t break and weighs next to nothing. This perception comes from its impressive strength-to-weight ratio. Indeed a pultruded carbon fiber tube exhibits incredible stiffness. However like all materials carbon fiber has limitations. It possesses vulnerabilities and costs remain high. One cannot simply swap out steel for carbon fiber without consequence.

What Makes carbon fiber square tube Seem So Grand?

Carbon fiber composites are incredibly strong for their weight. Manufacturers make them by weaving thin carbon strands into a fabric. Then they infuse this fabric with a resin like epoxy. This creates a stiff lightweight panel or a carbon fiber round tube. It’s fantastic for specific applications where saving weight matters most. Think aerospace parts or high-performance sports equipment.

The Truth About Its Vulnerabilities

Despite its strength carbon fiber isn’t invincible. It handles tension well but struggles with impact. A sharp blow can delaminate it causing catastrophic failure. Moreover carbon fiber doesn’t handle compression as well as steel. Its anisotropic properties mean its strength varies by direction. Consequently design needs careful consideration.

The Challenges Holding carbon fiber square tube Back: More Than Just Cost

Cost is a big barrier. Carbon fiber production is energy-intensive and slow. Specialized manufacturing processes further add to expenses. However other factors also limit its widespread use.

Production Pains: Slow and Pricey

Creating carbon fiber involves complex chemical processes and high temperatures. This makes it much pricier than steel or aluminum. Forming large components like a car chassis takes time. For example making a 1 carbon fiber tube involves precise winding or pultrusion. This contrasts sharply with fast metal stamping. Therefore mass production remains difficult.

Repair Riddles: Fixing the Unfixable

Repairing damaged carbon fiber structures is tricky and costly. Unlike metal which can often be bent back or welded carbon fiber requires specialized techniques. Damage often means replacing an entire section. This increases downtime and expense for consumers. Imagine fixing a dent in a steel car door versus a shattered carbon fiber panel.

Recycling Woes: A Green Dilemma

Recycling carbon fiber is a significant hurdle. Current methods are energy-intensive and degrade fiber quality. Most carbon fiber waste ends up in landfills. This clashes with modern sustainability goals. Developing efficient recycling solutions remains an active area of research.

When Carbon Fiber Fails: Real-World Examples

Even advanced materials can fail. Understanding these failures helps us grasp carbon fiber’s true limits. These aren’t just theoretical problems.

Impact Sensitivity: A Sudden Shatter

A prime example is its poor impact resistance. A minor collision that would dent a metal car can shatter a carbon fiber one. Bicycle frames or drone arms made from carbon fiber rectangular tube can splinter on impact. This makes carbon fiber unsuitable for structures needing resilience against unexpected forces.

Fatigue and Delamination: Invisible Weaknesses

Over time carbon fiber can experience fatigue. Microscopic cracks develop especially in areas of stress concentration. This leads to delamination where layers separate. These issues are hard to detect until it’s too late. Aerospace components undergo rigorous inspection to prevent such failures.

Material Alternatives: When Not to Use Carbon Fiber

Carbon fiber isn’t always the best choice. Many situations call for different materials. Understanding these alternatives saves both money and headaches.

Steel: The Workhorse of Industry

Steel remains an excellent choice for many applications. It’s affordable easy to produce and simple to repair. Its ductility means it bends before it breaks providing a safety net. For structures where weight isn’t paramount steel offers reliable performance. Consider bridges or everyday car frames.

Aluminum: Lightweight and Versatile

Aluminum provides a good balance of strength and weight. It’s lighter than steel and relatively easy to form. It also resists corrosion well. Many car body panels and aircraft structures use aluminum. It’s a common choice when seeking weight savings without carbon fiber’s expense.

Advanced Plastics: Innovations Abound

New engineering plastics offer impressive strength and flexibility. They can be molded into complex shapes easily. These materials suit many consumer goods and non-load-bearing components. Moreover some plastics are recyclable addressing environmental concerns.

What the Future Holds: Breakthroughs on the Horizon

Research continues to push carbon fiber’s boundaries. Scientists seek to overcome its current limitations. Exciting developments promise wider adoption in the future.

Lowering Production Costs: The Holy Grail

New manufacturing techniques aim to reduce carbon fiber’s price. Innovations like continuous pultrusion for square carbon fiber tube could lower costs significantly. Automated processes also promise to speed up production. This will make carbon fiber more accessible.

Enhanced Durability: Tougher Than Ever

Researchers explore ways to improve impact resistance. Integrating new materials or modifying resin systems could create tougher composites. Self-healing polymers are also a promising area. These innovations could make carbon fiber more robust for everyday use.

Sustainable Solutions: A Greener Future

Recycling technologies are improving steadily. New methods could efficiently recover carbon fibers without degradation. Bio-based resins are also under development. These advancements pave the way for more environmentally friendly carbon fiber products.

Smart Composites: Sensing Their Own Condition

Future carbon fiber structures might incorporate sensors. These “smart composites” could monitor their own integrity. They could detect damage early preventing catastrophic failures. This could revolutionize maintenance in aerospace and automotive industries. Such advancements will broaden its application range.