Anglies pluošto lakštai (Anglies pluošto lakštai pardavimui) dėl savo lengvumo, didelio stiprumo ir ilgaamžiškumo plačiai naudojami aviacijos, automobilių ir sporto įrangoje. Nesvarbu, ar tai būtų 3 mm anglies pluošto lakštas arba standartinis 4×8 anglies pluošto lapas, jų gamybos procesas yra tiksliai kontroliuojamas. Šiame straipsnyje paaiškinama anglies pluošto lakštų gamyba ir atsakoma į dažniausiai užduodamus klausimus, pvz. kaip pjauti anglies pluošto lakštus ir kur galima įsigyti anglies pluošto lakštų.

1 metodas: anglies pluošto lakštų gamybos procesas

1. Pirmtakų paruošimas

Procesas pradedamas nuo pirmtako (pvz., poliakrilnitrilo PAN), kuris karbonizuojamas, kad susidarytų anglies pluoštai.

2. Pluošto išlyginimas

Pluoštai išlyginami naudojant pultruziją, kad būtų užtikrintas anglies pluošto lakštų medžiaga pasižymi dideliu stiprumu.

3. Audimas į anglies pluošto audinį

Pluoštai audžiami į audinį (anglies pluošto lakštai) ir termiškai sutvirtinkite, kad paviršius būtų lygus.

4. Impregnavimas derva

Audinys derinamas su derva (anglies pluošto lakštai ir derva), kad padidėtų standumas ir patvarumas.

5. Kietėjimas karštyje ir slėgyje

Galiausiai lakštai sukietinami aukštu slėgiu, suformuojant tokius gaminius kaip Anglies pluošto lapas 4×8, kurį galima supjaustyti pagal dydį.

2 metodas: apdorojimas ir paraiškos

1. Anglies pluošto gamyba

Žaliavos ištempiamos karštyje, kad susidarytų anglies pluoštai, kurie yra anglies pluošto pagrindas. anglies pluošto lakštas.

2. Dervų maišymas ir liejimas

Anglies pluoštai sumaišomi su derva ir įspaudžiami į formas, kad būtų sukurti standartiniai dydžiai, pvz. 4×8 anglies pluošto lapas.

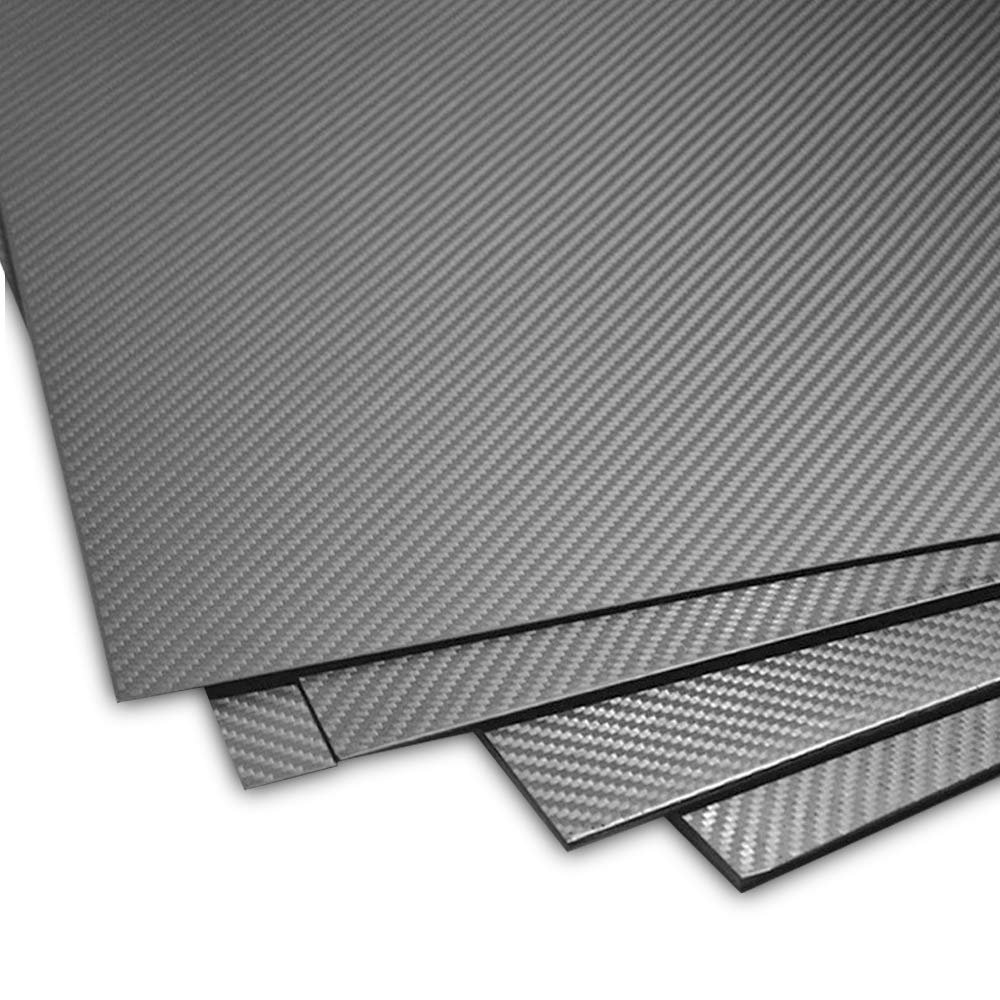

3. Paviršiaus apdorojimas

Lakštai gali būti dengiami, kad būtų atsparūs vandeniui arba apsaugoti nuo įbrėžimų, priklausomai nuo naudojimo poreikių.

4. Pjaustymas ir apdaila

Sukietėjusius lakštus galima pjaustyti (kaip pjauti anglies pluošto lakštus), skirtus įvairiems pramoniniams ar "pasidaryk pats" tikslams.

Kur įsigyti anglies pluošto lakštų?

Jei norite pirkti anglies pluošto lakštus, patikrinkite specializuotus kompozito tiekėjus arba internetines parduotuves (pvz., gamintojų svetaines). Įprastos galimybės yra šios 3 mm anglies pluošto lakštas ir anglies pluošto lakštai 4×8, tinka pramoniniams, "pasidaryk pats" ir aukščiausios klasės gaminiams gaminti.

Pagrindinės išvados:

✔ Pagaminta iš šildomų plastikinių pluoštų

✔ Derva suteikia tvirtumo ir standumo

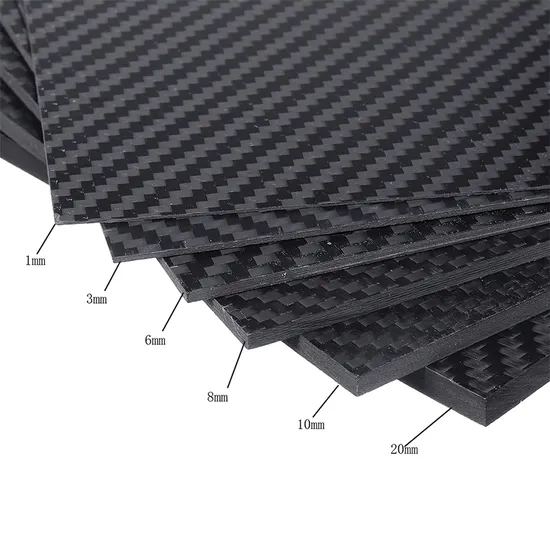

✔ Galimi tokie dydžiai kaip 3 mm ir 4×8

✔ Lengva pjaustyti ir pritaikyti

Nuorodos:

1.Kokio stiprumo yra anglies pluošto plokštės?

2.Kaip pasirinkti tinkamą anglies pluošto lakštą savo projektui?

3.Anglies pluošto strypų ir vamzdžių naudojimas dronų technologijose

4.Kaip pasirinkti anglies pluošto lakštus dronams?

5.Kuo skiriasi anglies pluošto lakštai ir anglies pluošto plokštės?

Atsakymų: 1