Klanten vragen vaak: Wat is het verschil tussen Rolgewikkelde koolstofvezel Buizen en gepultrudeerde buizen? En wat is het verschil tussen de oorspronkelijke koolstofkleur van Rolomwikkelde koolstofvezelbuis en het oppervlak van 3K stof?

1. Originele koolstofkleur

Kenmerken: Dit is de originele kleur van koolstofvezel, meestal diepgrijs of zwart, zonder zichtbare geweven textuur op het oppervlak.

Uiterlijk: Het ziet er eenvoudig en glad uit, zonder duidelijke patronen.

Toepassingen: Geschikt voor producten waarbij prestaties belangrijker zijn dan esthetiek, zoals industriële onderdelen of interne structurele onderdelen.

3K, 6K, 12K Stofoppervlak

Kenmerken: Deze nummers verwijzen naar het aantal filamenten in een koolstofvezelbundel (1K = 1000 filamenten). 3K, 6K en 12K stoffen zijn geweven van koolstofvezel, wat resulteert in een zichtbare geweven textuur op het oppervlak.

3K Stof: De fijnste weving, met een delicate en eersteklas uitstraling, ideaal voor hoogwaardige producten.

6K Stof: Iets grover dan 3K, maar nog steeds helder en evenwichtig qua esthetiek en prestaties.

12K Stof: De grofste weving, met een meer uitgesproken textuur, geschikt voor grotere onderdelen of toepassingen die een hogere sterkte vereisen.

Uiterlijk: Duidelijke raster- of diagonaalpatronen geven een verfijndere visuele aantrekkingskracht, perfect voor producten waarbij het uiterlijk van belang is.

Toepassingen: Vaak gebruikt in hoogwaardige producten zoals fietsframes, auto-onderdelen en sportuitrusting.

Belangrijkste verschillen

| Functie | Originele koolstofkleur | 3K/6K/12K Stofoppervlak |

|---|---|---|

| Uiterlijk | Eenvoudig, geen textuur, donkergrijs/zwart | Zichtbare geweven textuur, visueel aantrekkelijker |

| Prestaties | Uitstekend, ideaal voor interne structuren | Uitstekend, evenwicht tussen esthetiek en functionaliteit |

| Kosten | Relatief lager | 3K is duurder, 6K en 12K zijn betaalbaarder. |

| Toepassingen | Industriële onderdelen, interne componenten | High-end sportuitrusting, auto's, luxegoederen |

Hoe kiezen?

Als je prestaties belangrijk vindt en niet veel geeft om uiterlijk, ga dan voor originele koolstofkleur.

Als je een eersteklas look wilt met een hoge visuele aantrekkingskracht, kies dan voor 3K, 6K of 12K stofoppervlak (3K is het meest verfijnd, 12K is het brutaalst).

Samengevat is de originele carbon kleur meer ingetogen en praktisch, terwijl 3K, 6K en 12K stoffen oppervlakken een meer esthetische en gestructureerde uitstraling bieden. Je keuze hangt af van de positionering van het product en de behoeften van de klant!

Voeg hier je koptekst toe

Verschillende productieprocessen

Rolomwikkelde koolstofvezelbuis:

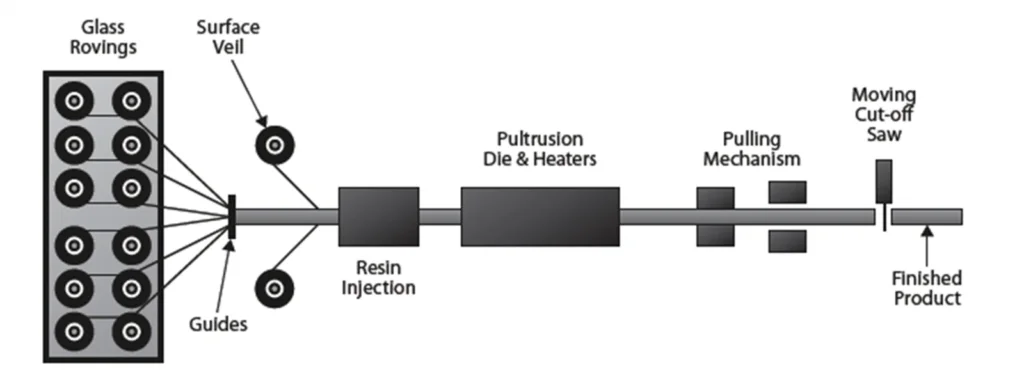

Net als bij het rollen van sushi wordt koolstofvezel prepreg in lagen op een mal gelegd en vervolgens verhit om uit te harden en te vormen. Met deze methode kunnen de vezelrichting en het aantal lagen flexibel worden aangepast, waardoor het geschikt is voor complexe vormen en producten met hoge prestaties.Gepultrudeerde buizen:

Net als bij het extruderen van noedels worden koolstofvezels door een harsbad getrokken en vervolgens door een verwarmde mal om de vorm direct te vormen. Deze methode is ideaal voor massaproductie en biedt een hoge efficiëntie en lage kosten.

Verschillende prestatiekenmerken

Rolomwikkelde koolstofvezelbuis:

Hoge sterkte, met de mogelijkheid om vezel layup richtingen te ontwerpen om te voldoen aan specifieke belastingseisen in verschillende richtingen.

Geschikt voor producten met hoge precisie en hoge prestaties, zoals onderdelen voor de ruimtevaart en hoogwaardige sportuitrusting (bijv. fietsframes, golfclubs).

Gepultrudeerde buizen:

Uniforme sterkte, maar met een vaste vezelrichting (meestal axiaal), waardoor ze ideaal zijn voor het hanteren van unidirectionele trekkrachten.

Geschikt voor gestandaardiseerde, in massa geproduceerde producten, zoals versterkingsmaterialen voor de bouw, stroomkabelkernen en industriële steunen.

Uiterlijk en afmetingen

Rolomwikkelde koolstofvezelbuis:

Glad oppervlak, in staat om complexere vormen en afmetingen te produceren, met een breed scala aan diameters, geschikt voor aangepaste behoeften.Gepultrudeerde buizen:

Het oppervlak kan lichte texturen hebben, met relatief vaste vormen en afmetingen, geschikt voor gestandaardiseerde productie.

Prijs en levertijd

Rolomwikkelde koolstofvezelbuis:

Hogere productiekosten en langere doorlooptijden, geschikt voor kleine series producten met een hoge toegevoegde waarde.Gepultrudeerde buizen:

Lagere productiekosten en snellere levering, geschikt voor kosteneffectieve producten in grote volumes.

Hoe kiezen?

Als je op maat gemaakte producten met hoge prestaties nodig hebt, zoals hoogwaardige sportuitrusting of onderdelen voor de ruimtevaart, kies dan voor Rolomwikkelde koolstofvezelbuis

Als je grote volumes gestandaardiseerde producten nodig hebt, zoals versterkingsmaterialen voor de bouw of industriële steunen, kies dan voor gepultrudeerde buizen.

Samengevat Rolomwikkelde koolstofvezelbuis en gepultrudeerde buizen hebben hun eigen voordelen. De keuze van het te gebruiken proces hangt af van je specifieke behoeften: of je nu hoge prestaties op maat nodig hebt of kosteneffectieve massaproductie.

2 reacties