Drones have become a game-changer across industries, from agriculture to surveillance. A key factor behind their success lies in advanced materials like carbon fiber rods and tubes. These components are transforming drone design, offering lightweight yet durable solutions that push performance boundaries. For customers looking to optimize their drones, understanding the role and benefits of rods and tubes is essential.

The Role of Carbon Fiber Rods and Tubes in Drones

Carbon fiber rods and tubes play a critical role in modern drone construction. Their high strength-to-weight ratio makes them ideal for improving flight efficiency and durability. Drones need to stay light to maximize battery life while remaining sturdy enough to handle environmental stresses like wind or sudden impacts.

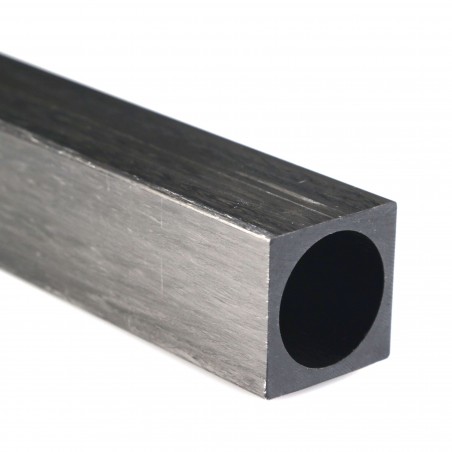

Manufacturers often rely on leveranciers van koolstofvezelbuizen to provide materials that balance these needs. Pultruded rods and tubes are particularly popular due to their consistent quality and customizable carbon fiber tube sizes. Whether square or round, these components offer unmatched rigidity and resilience.

Key Applications of Carbon Fiber Products in Drones

Structural Frames and Arms:

Drones require strong yet lightweight frames to support propellers and other components. Rods and tubes are perfect for this job. They reduce overall weight while maintaining structural integrity, enabling smoother flights and better maneuverability.Reinforcement in Wing Structures:

Fixed-wing drones benefit greatly from koolstofvezelbuizen. These materials reinforce wings, preventing flexing during flight. This ensures stability and precision, especially in applications like aerial mapping or surveillance.

Gimbals and Camera Mounts:

High-quality footage demands stable camera mounts. Rods and tubes provide the necessary rigidity while keeping weight low. This combination extends flight time and minimizes vibrations for clearer images.Landing Gear:

Durable landing gear is crucial for protecting sensitive equipment. Koolstofvezelbuizen absorb shocks effectively, reducing damage during rough landings. This extends the drone’s lifespan and lowers maintenance costs.

Benefits of Using Carbon Fiber Rods and Tubes in Drone Technology

Lightweight Design:

Carbon fiber rods significantly cut down drone weight. This improves battery efficiency and allows for longer flight times.Exceptional Durability:

These materials withstand harsh conditions, from high-speed flights to unpredictable weather. Their impact resistance ensures drones remain functional in challenging environments.High Rigidity:

With minimal flex, koolstofvezelbuizen maintain drone stability. This is especially important for heavy payloads or high-speed maneuvers.Customizable Options:

Carbon fiber tube manufacturers offer various sizes and shapes, including koolstofvezel buis vierkant designs. This flexibility allows for tailored solutions based on specific drone requirements.

The Future of Carbon Fiber Rods and Tubes in Drone Technology

As drone applications expand, so does the demand for advanced materials. Koolstofvezelbuizen will continue to dominate the industry due to their unmatched performance. Innovations in manufacturing processes are likely to produce even lighter and stronger variants.

For customers, partnering with reliable leveranciers van koolstofvezelbuizen ensures access to high-quality materials. Whether for commercial drones or specialized UAVs, these components will remain vital for achieving superior performance and durability.

Conclusie

Carbon fiber rods and tubes are revolutionizing drone technology. Their lightweight yet durable nature addresses critical challenges in drone design. From structural frames to camera mounts, these materials enhance performance across the board.

For those seeking reliable solutions, working with trusted carbon fiber tube manufacturers is key. With customizable carbon fiber tube sizes and shapes, the possibilities are endless. As drones evolve, carbon fiber rods and tubes will remain at the forefront, driving innovation and efficiency in the skies.

Referenties:

1.Het productieproces van koolstofvezelbuizen: Verschillen tussen draadwikkeling en pultrusie

2.Hoe hebben we onze klant geholpen bij het oplossen van productproblemen met onze koolstofvezelbuizen?

3.De kracht van koolstofvezelbuizen ontsluiten: De toekomst van lichtgewicht en flexibele telescopische buizen

4.Hoe de oppervlaktekwaliteit van koolstofvezelbuizen met een grote diameter te verbeteren

5.Waarom is de koolstofvezelbuis met een buitendiameter van 50 mm en een binnendiameter van 47 mm zo populair?

Eén reactie