Introduction: Carbon Fiber Parts Are Closer Than You Think

Carbon fiber parts rarely shout for attention. Instead these components hide in plain sight across daily life. From bikes rolling past cafés through cars waiting at stoplights this material quietly solves problems customers never want. Weight drops. Fatigue life improves. Parts last longer without drama. Because of that manufacturers keep choosing carbon fiber parts even when buyers never ask directly. In fact many people already rely on custom carbon fiber parts without realizing their presence.

Referencje:

1. Idealne włókno węglowe dla dronów: Materiały i opcje w arkuszach

2. Jak ciąć rury z włókna węglowego?

3. Zrozumienie testów twardości i ściskania rur z włókna węglowego

4. Włókno węglowe vs. wędka grafitowa: Która wędka najlepiej pasuje do Twoich potrzeb?

5. 8 błędów popełnianych przez inżynierów przy wyborze rur z włókna węglowego i sposoby ich uniknięcia

1. Bicycles and E-Bike Frames Using Carbon Fiber Parts

Cyclists crave speed comfort and control. Carbon fiber parts deliver all three. Frames forks seat posts and handlebars use layered fibers that flex slightly under load. That flex smooths road buzz without sacrificing power transfer. E-bike makers also rely on custom carbon fiber parts for frames that carry motors without ballooning weight. Riders notice longer range and easier handling even on hills.

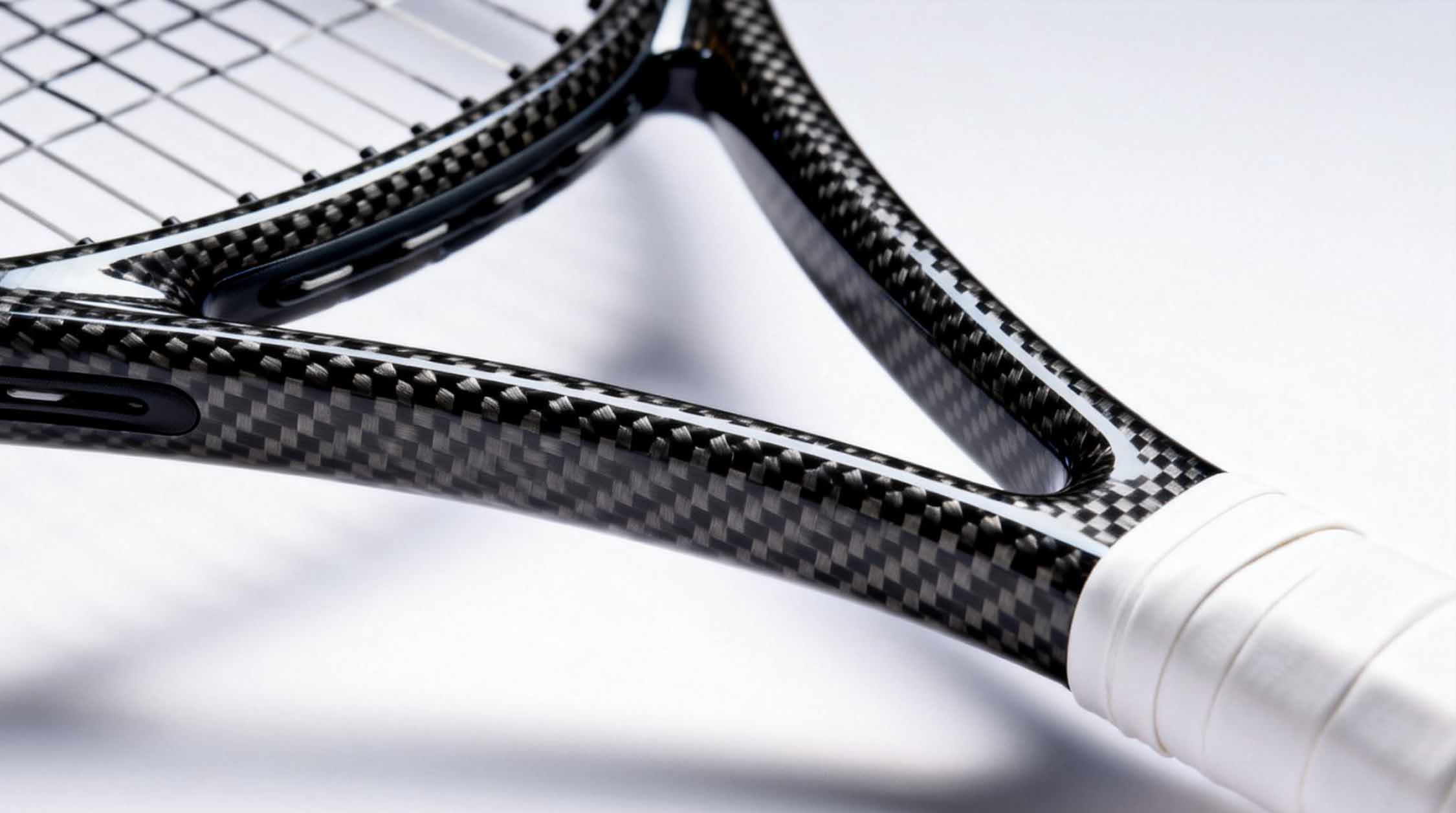

2. Sporting Goods: Racquets Clubs and Paddles with Carbon Fiber Parts

Athletes demand repeatable performance. Carbon fiber parts respond consistently swing after swing. Tennis racquets rely on tuned stiffness zones. Golf club shafts blend stability with snap. Paddle sports gain strength without wrist strain. Manufacturers fine-tune layups rather than adding bulk. As a result players enjoy gear that feels fast yet forgiving.

3. Helmets and Protective Gear Made with Carbon Fiber Parts

Safety equipment faces a tough challenge. Protection must rise while weight stays low. Carbon fiber parts help solve that equation. Helmets for cycling motorsports and climbing use composite shells that spread impact energy. Lighter helmets reduce neck fatigue during long use. Customers rarely notice material choice but they feel comfort immediately.

4. Consumer Electronics Housings and Internal Carbon Fiber Parts

Smartphones laptops and cameras chase thin profiles. Internal carbon fiber parts stiffen frames without metal thickness. Some brands hide carbon plates beneath plastic skins. Others reinforce hinges or tripod mounts. This approach limits flex damage while keeping devices sleek. Durability improves quietly which customers appreciate after months of use.

5. Home Appliances Using Carbon Fiber Parts

High-end vacuums robotic cleaners and even washing machines use carbon fiber parts internally. Motors spin faster when rotating mass drops. Handles feel lighter during daily chores. Engineers use composite rods shafts and braces rather than steel. Performance improves while energy use drops. Customers notice convenience rather than material science.

6. Automotive Parts and Interior Trim Featuring Carbon Fiber

Cars showcase carbon fiber parts more openly yet many pieces remain subtle. Structural braces seat frames and roof panels cut weight without sacrificing stiffness. Interior trim uses thin carbon skins for strength and style. Luxury brands like BMW integrate bmw carbon fiber parts across performance lines. Drivers feel sharper handling without knowing why.

7. Luggage Travel Gear and Cases with Carbon Fiber Parts

Frequent travelers want durability without shoulder strain. Suitcases now embed carbon fiber parts within shells or frames. Instrument cases camera boxes and drone carriers rely on composite panels for impact resistance. Weight savings allow higher airline limits. Users gain peace of mind during rough handling.

8. Furniture and Home Design Components Using Carbon Fiber Parts

Modern furniture experiments with minimal forms. Carbon fiber parts support tables chairs and shelving using slim profiles. Designers replace thick steel tubes with slender composite beams. That shift creates airy spaces without structural compromise. Customers enjoy lighter furniture that still feels solid during daily use.

9. Musical Instruments and Protective Cases Made with Carbon Fiber

Musicians value consistency across climates. Wood warps. Carbon fiber parts stay stable. Cellos violins guitar necks and instrument cases now use composite construction. Tone remains predictable despite humidity changes. Touring artists appreciate reliability during travel. The audience never notices yet performance stays sharp.

10. Medical Prosthetics and Mobility Aids Using Carbon Fiber Parts

Mobility devices demand strength reliability and comfort. Carbon fiber parts transform prosthetic limbs wheelchairs and braces. Reduced weight lowers energy use for patients. Elastic response improves gait efficiency. Custom carbon fiber parts allow precise fit without heavy hardware. For users this translates into independence rather than engineering.

Why Carbon Fiber Shows Up In So Many Products

Manufacturers adopt carbon fiber parts because customers demand better products. Weight reduction boosts comfort. Fatigue resistance extends lifespan. Design freedom enables thinner shapes. Once production scales costs fall. Composite knowledge spreads across industries. As tooling improves custom carbon fiber parts become accessible even for mid-volume goods.

How Manufacturers Decide Between Carbon Fiber and Traditional Materials

Design teams evaluate load paths environmental exposure and lifecycle cost. Carbon fiber parts shine where stiffness per weight matters most. Metals still suit heat or abrasion heavy roles. Smart products blend both. Customers benefit from balanced engineering rather than material hype.

How to Make Carbon Fiber Parts at Scale

Production methods vary. Some companies use prepreg layup for complex shapes. Others rely on pultrusion or compression molding for repeatability. Tooling choice depends on volume tolerance and budget. Knowing how to make carbon fiber parts efficiently helps brands meet demand without price shocks.

Custom Carbon Fiber Parts for Consumer Products

Customization drives differentiation. Brands commission custom carbon fiber parts for signature looks or performance edges. Automotive designers craft custom carbon fiber car parts for trims spoilers and panels. Sporting brands tune layups for athlete feedback. This flexibility explains rapid adoption across markets.

Are Carbon Fiber Parts Always Visible

Often they hide beneath paint plastic or fabric. Manufacturers prioritize function over display. Customers still gain benefits. Only performance models showcase exposed weave. Everyday goods quietly rely on composite cores while maintaining familiar appearances.

Future Growth of Carbon Fiber Parts in Daily Life

Automation reduces labor cost. Recycling improves sustainability. Design software predicts fiber behavior more accurately. These shifts push carbon fiber parts into mass products. Expect wider use across appliances mobility tools and urban transport. Many buyers will never notice yet satisfaction will rise.

Conclusion: Carbon Fiber Parts Already Shape Everyday Life

Carbon fiber parts already support activities people perform daily. Riding commuting working traveling playing. Manufacturers choose this material because problems disappear quietly. Lighter stronger longer-lasting products create better experiences. As production matures carbon fiber parts will fade further into background while benefits remain front and center.