Przy podejmowaniu decyzji między arkusze i płyty z włókna węglowegoWybór może mieć znaczący wpływ na wynik projektu. Oba materiały oferują wyjątkową wytrzymałość i lekkość, ale zrozumienie różnic między nimi pomaga wybrać odpowiedni materiał do swoich potrzeb.

Różne rodzaje arkuszy z włókna węglowego

Arkusze z włókna węglowego występują w różnych formach, z których każda jest przeznaczona do określonych zastosowań. Arkusze te są jednak znane z imponującego stosunku wytrzymałości do masy i są szeroko stosowane w przemyśle lotniczym, motoryzacyjnym i sprzęcie sportowym.

Arkusze z włókna węglowego do infuzji próżniowej

Infuzja próżniowa to popularna metoda produkcji wysokiej jakości arkuszy z włókna węglowego. Technika ta zapewnia równomierne rozprowadzanie żywicy, tworząc produkt, który jest zarówno wytrzymały, jak i lekki. Idealne dla komponentów lotniczych i pojazdów o wysokich osiągach, arkusze infuzji próżniowej zapewniają doskonałą równowagę między sztywnością i elastycznością.

Arkusze formowane tłocznie z włókna węglowego

Formowanie tłoczne polega na zastosowaniu ciepła i ciśnienia do kształtowania arkuszy włókna węglowego. W wyniku tego procesu powstaje gęsty, trwały materiał nadający się do zastosowań konstrukcyjnych. Arkusze formowane ciśnieniowo są często stosowane w maszynach przemysłowych, oferując odporność na uderzenia i zużycie.

Różne rodzaje płyt z włókna węglowego

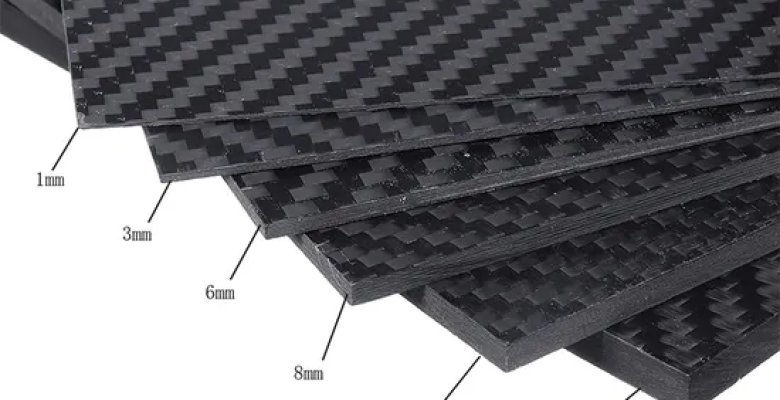

Płyty z włókna węglowego są grubsze i sztywniejsze w porównaniu do arkuszy. Są one przeznaczone do zastosowań wymagających wysokiej integralności strukturalnej i minimalnej elastyczności.

Standardowe płyty z włókna węglowego

Standardowe płyty z włókna węglowego są produkowane przy użyciu warstw tkanych włókien węglowych połączonych żywicą. Płyty te są powszechnie stosowane w robotyce, częściach samochodowych i sprzęcie sportowym. Ich sztywność i niska waga sprawiają, że idealnie nadają się do wymagających środowisk.

Quasi-izotropowe płyty z włókna węglowego

Płyty quasi-izotropowe zostały zaprojektowane tak, aby zapewnić jednolitą wytrzymałość we wszystkich kierunkach. Taka konstrukcja sprawia, że nadają się one do zastosowań, w których działają siły wielokierunkowe, np. w dronach lub konstrukcjach architektonicznych

Zastosowania arkuszy z włókna węglowego

Arkusze z włókna węglowego znajdują zastosowanie w różnych branżach ze względu na swoją wszechstronność.

Lotnictwo i kosmonautyka

W przemyśle lotniczym arkusze z włókna węglowego przyczyniają się do produkcji lżejszych i mocniejszych komponentów samolotów, poprawiając wydajność paliwową i osiągi.

Motoryzacja

W sektorze motoryzacyjnym arkusze te są wykorzystywane do produkcji lekkich paneli nadwozia i części konstrukcyjnych, zwiększając prędkość i sterowność.

Sprzęt sportowy

Producenci sprzętu sportowego wykorzystują arkusze włókna węglowego do tworzenia wysokowydajnego sprzętu, takiego jak rowery, rakiety tenisowe i sprzęt ochronny, przynosząc korzyści sportowcom dzięki zmniejszonej wadze i zwiększonej wytrzymałości.

Arkusze z włókna węglowego dostępne w grubościach 1 mm, 2 mm, 3 mm i 4 mm

Arkusze z włókna węglowego są dostępne w różnych grubościach, od 1 mm do 4 mm, spełniając różne wymagania dotyczące wytrzymałości i elastyczności. Arkusze te mogą być przycinane do rozmiarów do 2 metrów kwadratowych, zapewniając opcje dla różnorodnych zastosowań.

Arkusze 1 mm

Idealny do zastosowań kosmetycznych lub komponentów wymagających eleganckiego wyglądu bez zwiększania wagi.

Arkusze 2 mm

Idealny do umiarkowanych zastosowań konstrukcyjnych, w których wymagana jest równowaga między elastycznością a wytrzymałością.

Arkusze 3 mm

Nadaje się do bardziej wytrzymałych konstrukcji, oferując zwiększoną sztywność i trwałość.

Arkusze 4 mm

Zaprojektowany do ciężkich zastosowań, zapewnia maksymalną wytrzymałość i sztywność.

Niestandardowe panele z włókna węglowego

Niestandardowa produkcja pozwala na dostosowanie panele z włókna węglowego aby spełnić określone wymagania projektowe. Niezależnie od tego, czy chodzi o zastosowania przemysłowe, czy projekty osobiste, niestandardowe panele mogą być zaprojektowane zgodnie z precyzyjnymi specyfikacjami, zapewniając optymalną wydajność i dopasowanie.

Ramki do tablic rejestracyjnych z włókna węglowego

Ramki tablic rejestracyjnych z włókna węglowego łączą styl z trwałością. Ramki te oferują elegancki, nowoczesny wygląd, jednocześnie chroniąc tablicę rejestracyjną przed uszkodzeniem. Lekkie i odporne na korozję, są doskonałym dodatkiem do każdego pojazdu, który chce połączyć estetykę z funkcjonalnością.

Wybór między Arkusze i płyty z włókna węglowego zależy od konkretnych wymagań danego projektu. Zrozumienie właściwości i zastosowań każdego z nich zapewnia podjęcie świadomej decyzji, której efektem będzie doskonały produkt końcowy. Niezależnie od tego, czy potrzebujesz elastyczności i lekkości, czy też sztywności i wytrzymałości, włókno węglowe oferuje rozwiązanie dostosowane do Twoich potrzeb.

Jedna odpowiedź