FIND YOUR RELIABLE MANUFACTURER OF CARBON FIBER SHEET

Why Choose Us

Our company stands out by offering solutions built around your needs. Let’s break down why automotive manufacturers, hobbyists, and engineers trust us.

Customizable

In addition to size, surface finishing, carbon fiber tow, grade, color, and weave pattern can all be customized to meet your unique requirements and ideas.

One-Stop Solution

Our inventory includes ready-to-ship carbon fiber sheets, many options, and custom orders. With competitive pricing and rapid delivery, starting your project takes minutes.

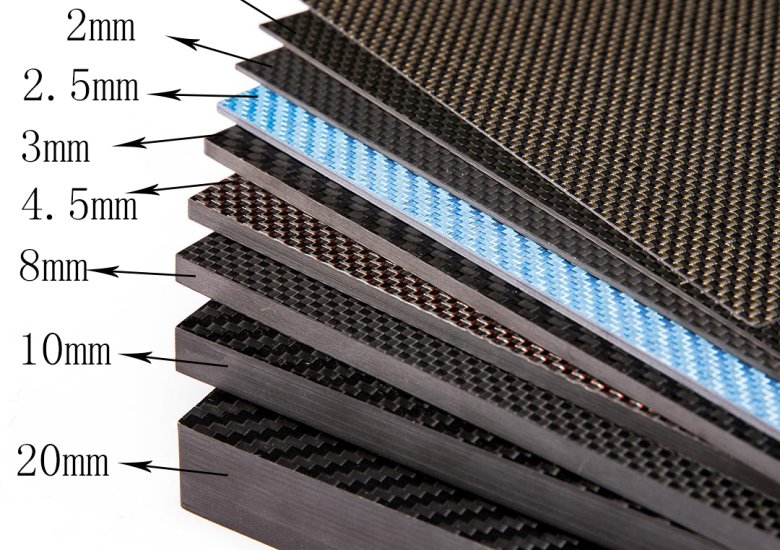

Size & Thickness

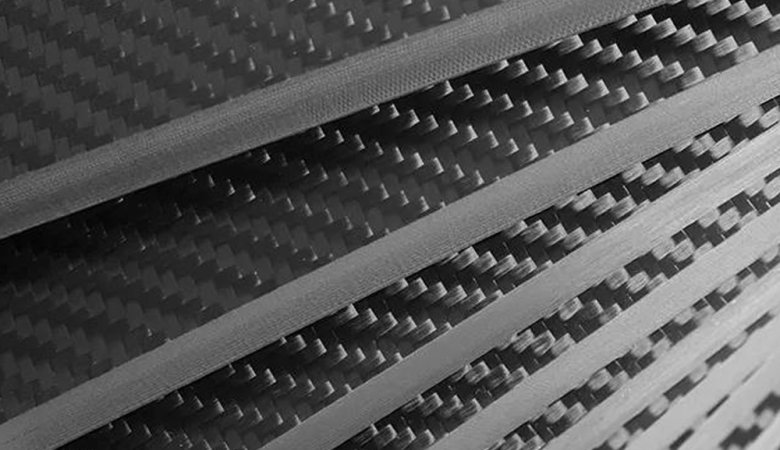

Due to the Carbon Fiber Sheets are laminated and made using autoclave molding process, any size and thickness can be customized based on dimension of the composite autoclave

- Standard sizes: 400x400mm, 400x500mm, 500x500mm, 500x600mm, 500x1000mm, 600x1000mm, 1000x1000mm, 1000x1200mm,and more

- Length: 10 (min.) – 1500 (max.)

- Width: 10 (min.) – 3000 (max.)

- Thickness: 0.2 (min.) – 60mm (max.)

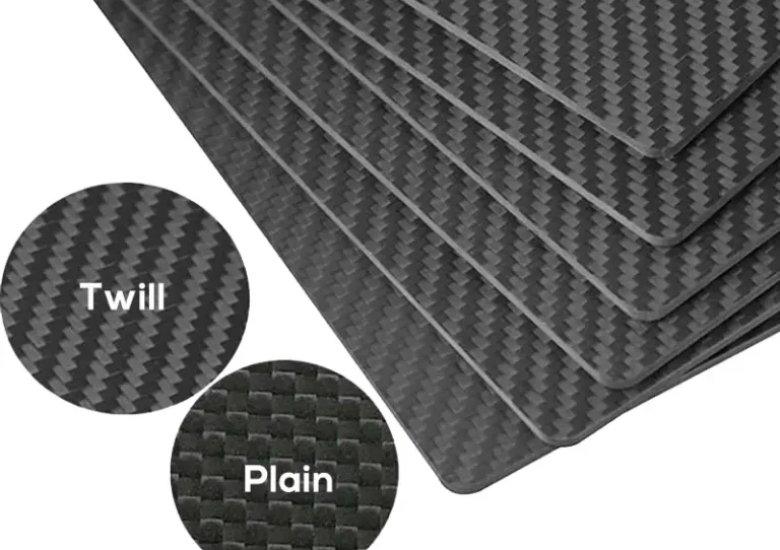

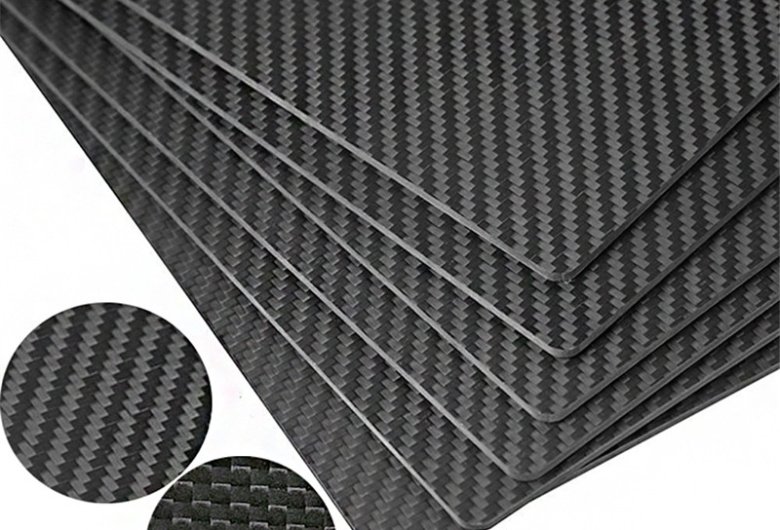

Weave

Diverse applications present unique demands for carbon fiber. To meet these demands, carbon fiber weaving technology has continuously evolved, giving rise to a variety of weaving patterns.

- Twill Weave

- Plain Weave

- Satin Weave

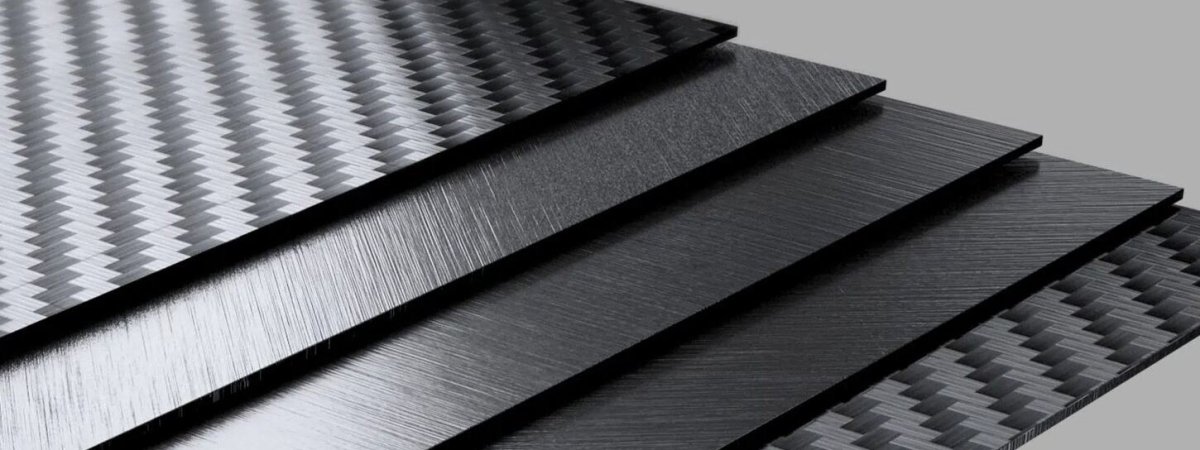

Surface Finishing

For the different aesthetic preferences and application needs, the surface finishing can be customized according to your requirement.

- Glossy

- Semi-Matte

- Matte

Carbon Fiber Tows

“K” represents one thousand, is used to indicate the number of fibers in each bundle. The number is bigger, the size of bundle is wider.

- 1K

- 3K (Most Common)

- 6K

- 12K

Carbon Fiber Strength Grade

We understand that different applications demand different levels of performance. That’s why we offer 3 of the most popular carbon fiber grades to meet your specific needs

- T300 (Most Common)

- T700

- T800

What is a Carbon Fiber Sheet?

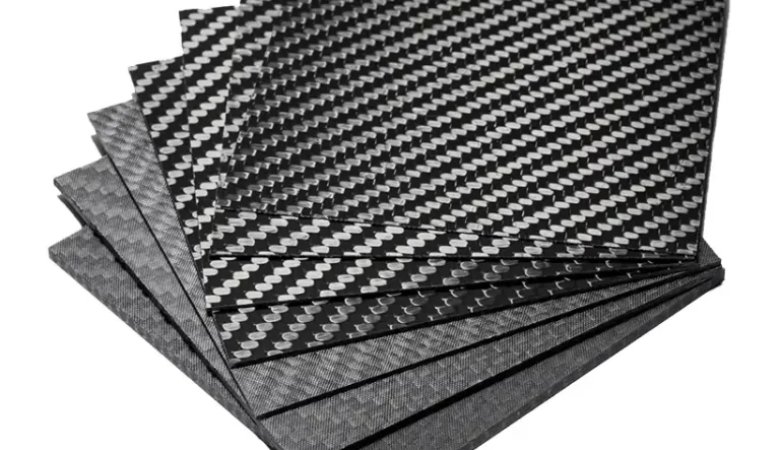

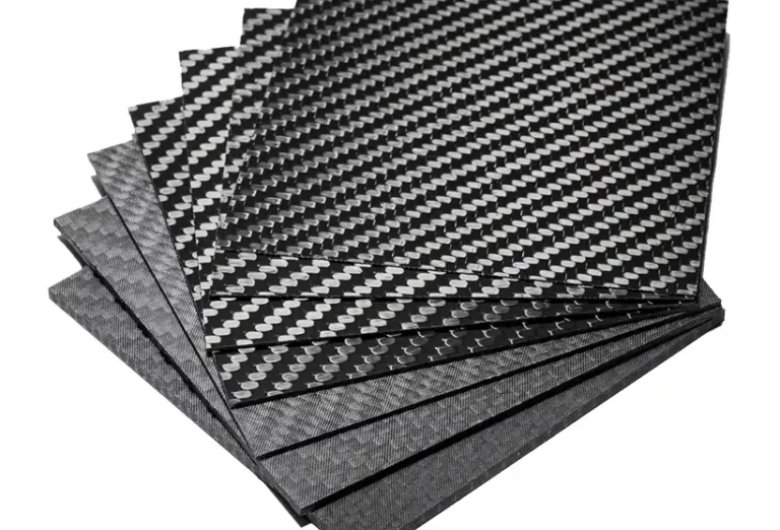

Carbon fiber sheets have become a game-changer in modern materials science. These sheets, crafted from tightly woven carbon strands, offer an impressive combination of lightness, strength, and versatility. But what exactly are they, and why do customers increasingly choose them over traditional materials like steel or aluminum?

What Makes Carbon Fiber Sheets Unique?

A Carbon fiber panel is created by layering thin carbon fiber strands into a resin matrix, then curing the structure under heat and pressure. This process produces a rigid, lightweight panel with exceptional durability. Customers often find themselves amazed at the sheer strength-to-weight ratio these sheets provide. When you hold one, it feels almost weightless yet remarkably robust.

Compared to metal alternatives, carbon fiber sheets resist corrosion, tolerate extreme temperatures, and display flexibility in design. These properties make them ideal for industries where performance is key. Aerospace engineers, automotive innovators, and even hobbyists rely on these sheets to build stronger, lighter, and more efficient products.

Solving Real-World Problems with Carbon fiber plate

Every buyer faces unique challenges, and Carbon fiber plate frequently offer innovative solutions. Are you frustrated by parts wearing out due to rust? Carbon fiber panels resist moisture and harsh chemicals. Tired of products weighing too much and costing extra fuel? These sheets cut down on weight while maintaining strength.

For industrial customers, one major hurdle is creating complex parts without sacrificing performance. Carbon fiber panel can be machined, cut, or molded into intricate shapes. The customizable nature saves time and minimizes waste. In industries like marine construction or drone manufacturing, these qualities are invaluable.

Key Applications of Carbon fiber plate

From sports equipment to space exploration, these sheets find use in countless fields. Cyclists appreciate carbon fiber for building ultra-light frames that improve speed. Musicians even turn to carbon fiber for durable, acoustically unique instruments. Customers crafting custom cars or race vehicles value the sheets’ ability to reduce weight without weakening essential components.

Architects also incorporate Carbon fiber panel into structures that require lightweight yet strong materials. The design flexibility enables creative solutions, such as curved panels or striking façades, while maintaining resilience against weather.

Choosing the Right Carbon Fiber Sheet for Your Needs

When selecting a Carbon fiber panel, understanding your specific requirements is crucial. Do you need a glossy finish for aesthetic appeal? Consider high-grade sheets with UV-resistant coatings. Are stiffness and minimal deflection critical for your application? Opt for sheets with a thicker core or a unidirectional weave.

Customers often face confusion about sizes and thicknesses. Luckily, most suppliers offer custom-cut options tailored precisely to your project. Always verify the sheet’s specifications, including tensile strength, modulus, and thermal resistance, before purchasing. Ensuring compatibility can save you from costly errors.