Проекты Структурные преимущества Стержни из углеродного волокна в строительных проектах. Углеродное волокно устраняет эту проблему. Эти стержни не поддаются коррозии, сохраняя устойчивость в прибрежных районах с высоким содержанием соли, промышленных зонах и экстремальных погодных условиях. Благодаря усталостной прочности конструкции служат дольше без постепенного ослабления под воздействием повторяющихся циклов нагрузок. Такая надежность означает меньшее количество ремонтов, снижение эксплуатационных расходов и долгосрочную экономию.

Универсальность дизайна и точность изготовления

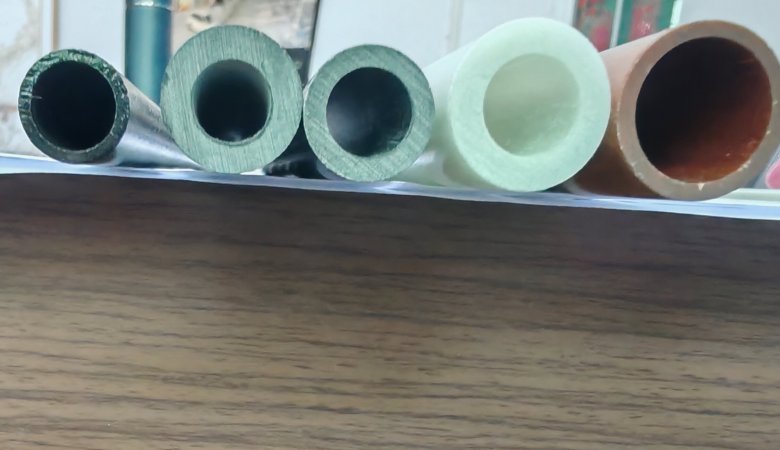

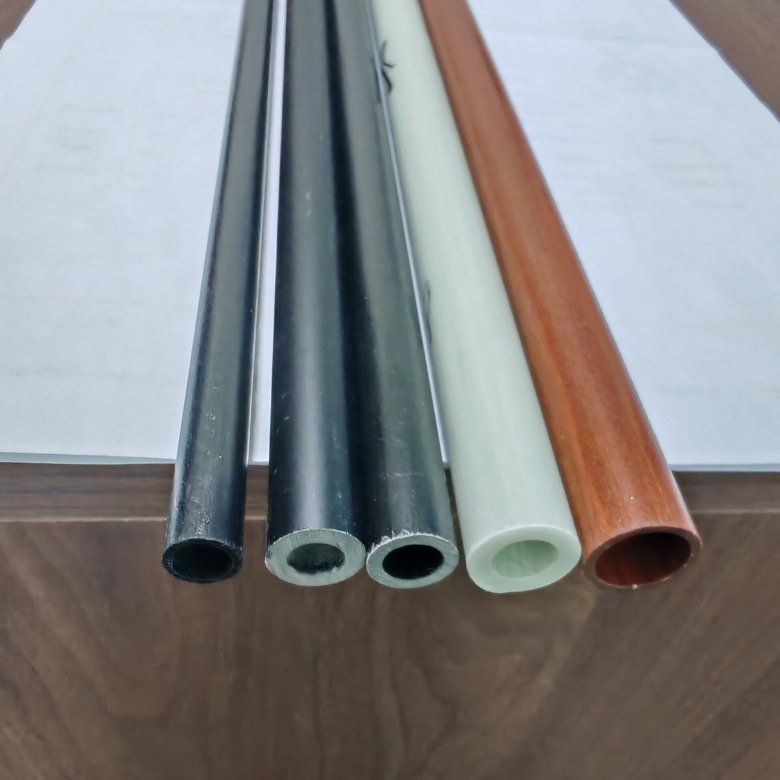

Строительство не является универсальным. Стержни из прессованного углеродного волокна адаптируются к различным требованиям проектов, предлагая нестандартные диаметры, формы и механические свойства. Их структурная целостность позволяет создавать замысловатые архитектурные проекты и выполнять точные работы. В отличие от металлических альтернатив, углеродное волокно не деформируется при перепадах температур. При армировании бетона, укреплении фасадов или поддержке динамических конструкций эти стержни обеспечивают непревзойденную адаптивность без компромиссов.

Применение твердых Стержни из углеродного волокна в ключевых отраслях промышленности

1. Аэрокосмическая промышленность и беспилотники

Пропеллерные валы: Высокопрочные и легкие компоненты снижают инерцию вращения.

Антенна поддерживает: Поддерживайте устойчивые к вибрациям коммуникационные массивы.

Спутниковые каркасы: Жесткие конструкции выдерживают суровые условия космоса.

2. Автомобили и гонки

Приводные валы: Снижение веса, улучшение ускорения и энергоэффективности.

Компоненты подвески: Минимизация деформации при динамических нагрузках.

Рулевые колонки: Усиливают контроль водителя благодаря устойчивой к усталости конструкции.

Шатуны из углеродного волокна: Повышение долговечности при снижении массы в высокопроизводительных двигателях.

3. Промышленное оборудование и автоматизация

Роботизированные руки: Точные, малогабаритные компоненты механизма.

Автоматизированные справочники по оборудованию: Обеспечение точности конструкции в системах ЧПУ и 3D-печати.

Опоры для лазерного выравнивания: Стабильность в чувствительных оптических приборах.

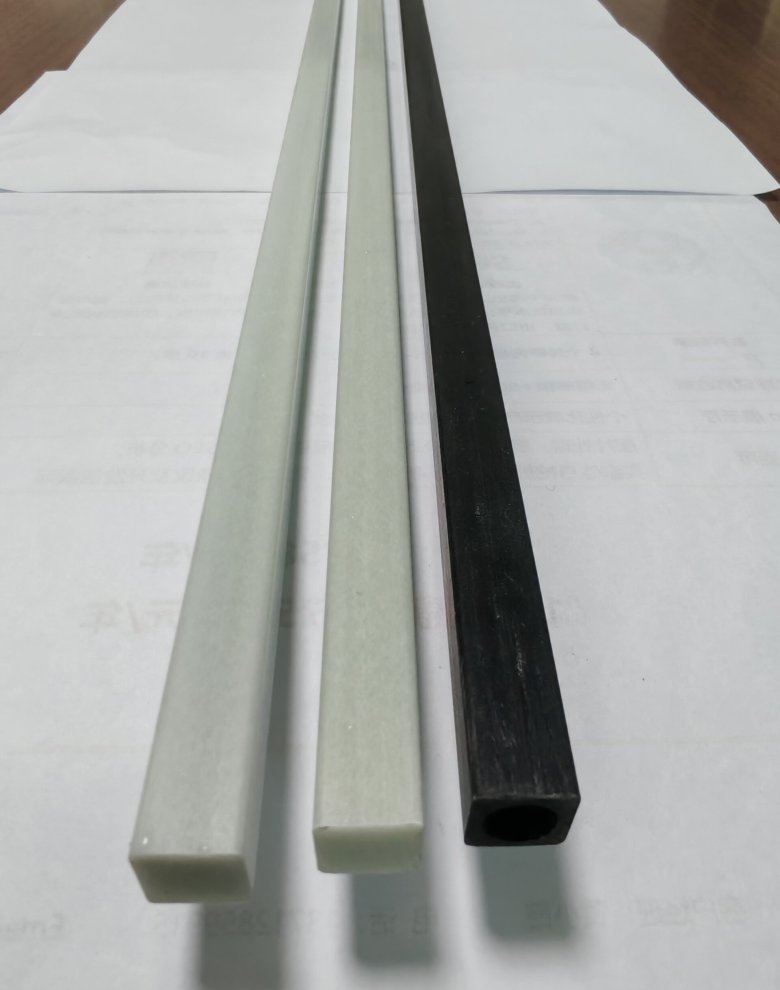

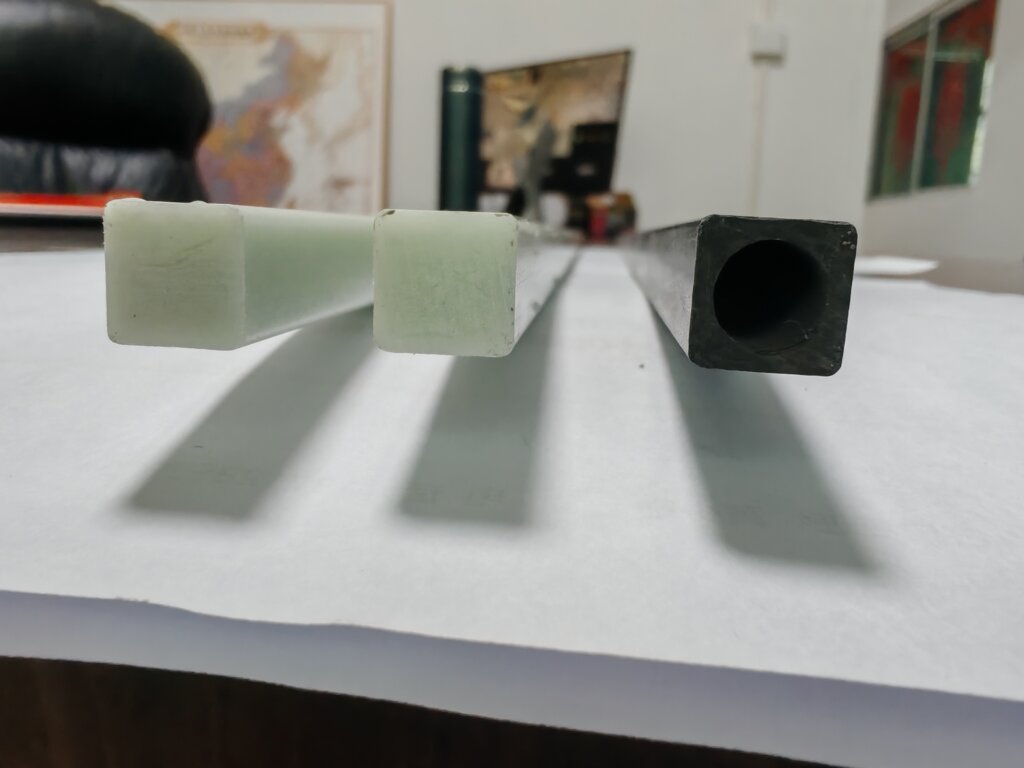

Квадратные стержни из углеродного волокна: Идеально подходит для создания жестких и легких каркасов.

4. Спортивное оборудование и оборудование для активного отдыха

Валы для гольф-клубов: Улучшите скорость замаха, не жертвуя контролем.

Рыболовное удилище из углеродного волокна: Высокая чувствительность и прочность для рыболовов.

Стрелы для стрельбы из лука: Легкий вес и превосходные летные характеристики.

Походные палки: Прочные и легкие для занятий на выносливость.

5. Медицинские и реабилитационные устройства

Подставки для хирургических инструментов: Готовность к стерилизации и точность конструкции.

Протезные разъемы: Прочность при снижении нагрузки на пациента.

Реабилитационные рамы: Прочные и удобные структурные усиления.

6. Электроника и прецизионные устройства

Поддержка карданного шарнира камеры: Сведите к минимуму нежелательные движения.

Полупроводниковые стержни-зонды: Стабильность размеров при высокоточном тестировании.

Компоненты для рассеивания тепла: Управление теплом в мощных приложениях.

7. Энергетика и экологическая инженерия

Датчики для ветряных турбин: Устойчивость к постоянным нагрузкам.

Крепления для слежения за солнечными батареями: Поддерживайте оптимальные углы наклона панелей.

Неметаллические ядерные компоненты: Радиационно-стойкие опорные элементы.

8. Военные и оборона

Стабилизаторы для огнестрельного оружия: Снижение отдачи без увеличения массы.

Тактические рамы для беспилотников: Легкий вес с преимуществами скрытности.

Корпуса оптических прицелов: Сохраняют центровку при интенсивной эксплуатации.

9. Пользовательские и исследовательские приложения

Лабораторные опорные рамы: Идеально подходит для электронных микроскопов и научных приборов.

Прототипы космических аппаратов: Проверка легких аэрокосмических конструкций.

Подводная робототехника: Коррозионно-стойкие конструктивные элементы.

Заготовки для стержней из углеродного волокна: Идеально подходит для изготовления на заказ и точного машиностроения.

10. Шатуны из углеродного волокна для хоббийных моделей и DIY инноваций

Шасси для RC автомобилей: Сила без излишеств.

Укрепление инструментов: Гитарные шейки, валы для гравировальных инструментов.

Креативные инженерные проекты: Легко поддается формовке, склеиванию и сверлению.

Почему Стержни из углеродного волокна Доминирование в высокопроизводительных приложениях

Легкий вес: Плотность стали 25%, алюминия 66%.

Сила: Прочность на разрыв превышает 3 000 МПа.

Устойчивость к усталости: Сохраняет целостность при многократных нагрузках.

Устойчивость к коррозии: Не подвержен воздействию влаги, химикатов и ультрафиолетового излучения.

Устойчивость размеров: Низкое тепловое расширение предотвращает структурные сдвиги.

Настраиваемый: Адаптируемые диаметры, длина и обработка поверхности.

Стержни из углеродного волокна: Будущее строительства и не только

Для отраслей промышленности, где требуются экстремальная прочность, точность и долговечность, твердосплавные стержни из углеродного волокна являются идеальным решением. Их способность заменять традиционные металлы в сложных условиях создает безграничные возможности в машиностроении, инфраструктуре и дизайне. Будь то укрепление высокопроизводительных машин, новаторские аэрокосмические приложения или оптимизация повседневных структурных элементов, эти стержни по-новому определяют современные материалы. Инвестиции в углеродное волокно означают внедрение инноваций, минимизацию затрат и обеспечение долговременных характеристик на десятилетия вперед.

Ссылки:

1.Выбор правильной трубки из углеродного волокна для нахлыстового удилища

2.Удилище из углеродного волокна и графита: Что лучше всего подходит для ваших нужд

3.Раскрытие возможностей трубок из углеродного волокна: Будущее легких и гибких телескопических труб

4.Понимание твердости и испытаний на сжатие трубок из углеродного волокна

5.Как выбрать подходящие трубки из углеродного волокна для вашего проекта