Why Carbon Fiber Kevlar Sheets Matter in Racing

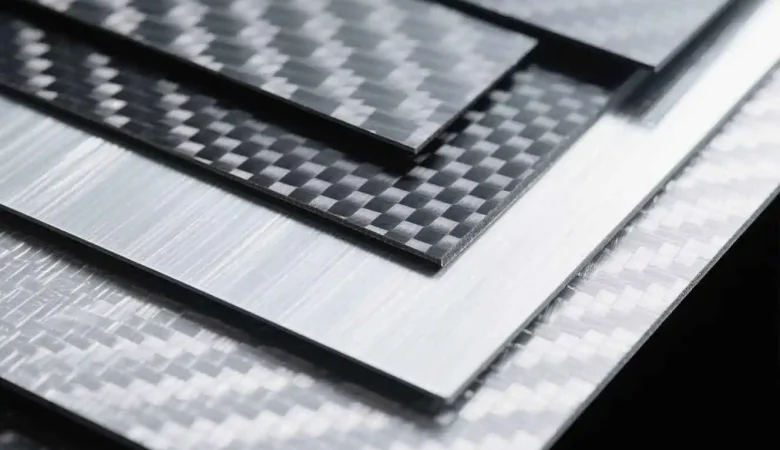

Weight ruins speed. Drag kills time. High-performance vehicles need every ounce cut and every surface optimized. That’s where carbon fiber kevlar sheets step in. Not only do they trim fat without breaking strength but they also take abuse like champs. Whether you’re tearing up a racetrack or bombing corners on a sportbike, these hybrid composite sheets serve both looks and longevity.

Why Weight Reduction Is Critical in Racing

Dead weight slows everything—braking, cornering, throttle. Less weight means quicker acceleration and tighter handling. Drop ten pounds from a race fairing or undertray and suddenly your lap time falls.

Kevlar mixed with carbon fiber offers something wild: strength under stress with flexibility where needed. Lightweight doesn’t mean fragile. No need for metal when carbon fiber composite sheets handle the hit without denting. Perfect for aggressive builds where form follows function.

Performance and Aesthetic Benefits of Carbon Fiber Kevlar Sheets

Speed is one reason. Strength is another. But don’t ignore the visual payoff. Matte finishes, glossy twill weaves, and even bold colors like red or blue carbon fiber sheet blends give vehicles a race look without spray guns.

Keeps structure rigid under heat and load

Reduces fatigue on metal parts

Doesn’t rot, rust, or crack

Works for load-bearing and cosmetic panels

Want more? Start buying carbon fiber sheets cut to spec. Don’t settle for fiberglass if performance matters.

References:

1. DIY Carbon Fiber Parts for Custom Motorcycles: A Beginner’s Journey into Lightweight Strength

2.How We Helped Our Client Solve Product Issues with Our Carbon Fiber Tubes?

3.Building Your Ultimate Lightweight Drone Frame: A Carbon Fiber Sheets Step-by-Step Guide

4.How to Improve the Surface Quality of Large Diameter Carbon Fiber Tubes

5.How to Modify Custom Carbon Fiber Parts Without Losing Its Strength

Top 5 Carbon Fiber Kevlar Sheet Upgrades

Ready for a stronger ride that looks sharp and performs sharper? Check out these five killer uses for carbon fiber kevlar sheets on performance bikes and race cars.

1. Custom Fairings and Side Panels (Motorcycles)

Motorcycle riders demand lightweight shells that won’t shatter on impact. Kevlar-reinforced panels do just that. Use carbon fiber board sheets or carbon fiber abs plastic sheet for side pieces that stay tight under speed.

Tougher than fiberglass

Shock-resistant from lowsides

Easy to refinish or wrap

Bonus: Wrap panels in carbon fiber decal sheets for low-cost visuals without sacrificing actual carbon performance underneath.

2. Aero Splitters and Diffusers (Cars)

Racecars live or die on downforce. Want that edge? Fabricate splitters using layered carbon fiber kevlar sheets. They flex just enough on contact but hold shape at 140 mph.

Better than aluminum at resisting road scrape

High impact resistance from front-end debris

Won’t snap under track heat

Add carbon fiber adhesive sheets or carbon fiber 3m sheets to dress bare metal or finish undertrays.

3. Seat Backing and Inner Structure Panels

Stop wasting weight behind the scenes. Replace steel seat brackets or composite shells with ultra-light carbon fiber acrylic sheets. Mix in Kevlar layers for crash resistance. Strong. Light. Invisible.

Some tuners even use carbon fiber kydex sheet to shape rear interior panels in stripped-out builds.

Thin but supportive

Works for both bikes and track cars

Resists tearing on bolted components

4. Reinforced Fender Liners and Inner Fenders

Gravel and race debris chew up wheel wells fast. Carbon fiber kevlar sheets reinforced with resin can form inner liners that shrug off rocks like armor. Unlike pure carbon, Kevlar won’t splinter on sharp impact.

Use carbon fiber abs sheet if you need flexibility with added thermal resistance.

5. Custom Tank Covers or Dash Inserts (Style + Function)

Want something louder than paint? Grab a blue carbon fiber sheet or dyed composite blend. These materials pop under clear coat. Even dashboards get race-ready with properly molded inserts made from heat-safe carbon fiber density sheets.

These aren’t just show mods. They withstand constant sun, shock, and vibration from aggressive rides.

Can You Bend Carbon Fiber Sheets?

Yes—but only with care. Can you bend carbon fiber sheets? Technically yes. Use heat, careful layup, or flexible variants like carbon fiber abs sheet or carbon fiber kydex sheet. Kevlar layers help reduce cracking along sharp folds.

But always test scraps before shaping final parts. Fold wrong and you’ll delaminate layers or ruin tension.

Smart Choices for Smart Builders

Whether you’re modding a street-legal track monster or cutting grams off a Ducati, carbon fiber kevlar sheets bring style with function. Want peel-and-stick ease? Try carbon fiber adhesive sheets. Need serious strength with heat shielding? Roll with carbon fiber composite sheets or carbon fiber abs plastic sheet in structural builds.

Mix Kevlar in where impact might happen. Use standard carbon weave elsewhere. Balance cost, durability, and performance smartly.

Summary: Build Light, Stay Fast, Look Sharp

Carbon fiber kevlar sheets change how racers build. Lighter panels, tougher structure, better looks. Every ounce counts. Start with seat backs. Wrap the tank. Reinforce the nose. Buy wisely, bend carefully, and beat weight with strength.

Skip steel. Leave fiberglass behind. Go fast with smarter parts today.

3 Responses