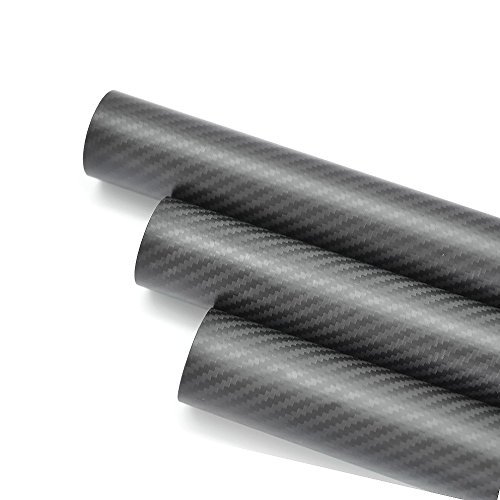

Karbon fiber borular artık sadece niş bileşenler değil. Modern yöntemler sayesinde fabrikalar artık bunları verimli bir şekilde üretiyor. Otomotiv üreticileri için bu değişim, oyunun kurallarını değiştiren avantajların kilidini açıyor. Seri üretim karbon fiber boruların neden önemli olduğunu ve gerçek dünyadaki sorunları nasıl çözdüğünü inceleyelim.

Karbon fiber borular otomotiv, havacılık ve sanayi sektörlerinde popülerliği artmıştır. Peki üreticiler üretimi verimli bir şekilde ölçeklendirebilir mi? Kesinlikle. Aşağıdaki gibi malzemelerdeki gelişmeler Toray karbon fiber ve aşağıdaki gibi süreçler hidro daldırma karbon fiber kaplamalar artık kaliteden ödün vermeden yüksek hacimli üretim yapılmasını sağlıyor. Bunun nasıl çalıştığını ve projeleriniz için neden önemli olduğunu inceleyelim.

Hafif Güç Merkezi: Performansı İleriye Taşıyor

10-22 karbon fiber gibi malzemelerle üretilen otomobiller kas kaybetmeden ağırlıktan kurtulur. Ağır çeliği, aşırı stresle başa çıkabilen tüy kadar hafif borularla değiştirdiğinizi hayal edin. Toray karbon fiber, eşsiz güç/ağırlık oranları sunarak burada baskındır. Daha az kütle, daha hızlı hızlanma ve daha keskin yol tutuşu anlamına gelir. Ayrıca, daha ince araç kütlesi yakıt verimliliğini 10%'ye kadar artırarak pompada nakit tasarrufu sağlar.

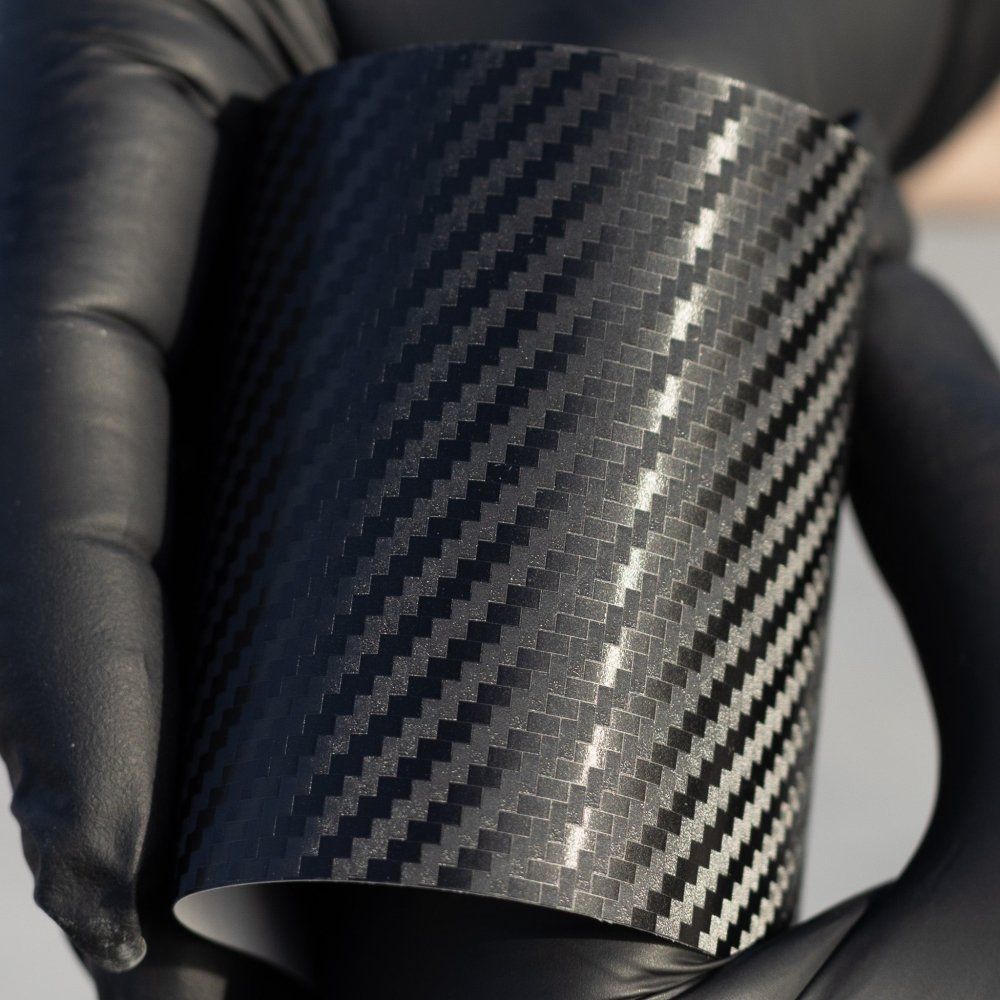

Çelik yerine karbon şasi bileşenler araç ağırlığını 50%'ye kadar azaltıyor. Daha hafif arabalar demek gelişmiş yakıt verimliliğiemisyon düzenlemeleri sıkılaştıkça en önemli öncelik haline geliyor. Birleştirmeyi hayal edin 5mm karbon fiber levhalar ile siklami TPU tüpler şok emilimi için - bu ikili yapısal bütünlüğü artırırken ağırlığı azaltır. Artı, karbon fiber doku ekstra adımlar olmadan şık bir estetik katar.

Özel Şekiller, Sonsuz Seçenekler

Otomobil üreticileri esneklik istiyor. Hidro daldırma karbon fiber teknikleri ile tüpler, yapısal tavizler vermeden gösterişli dokular veya renkler kazanır. İhtiyacınız olan 5mm karbon fiber levha kıvrımlara kalıplanmış? Sorun değil. Tedarikçiler, fibra de carbono piezaları dar şasi alanlarına rahatça sığan vahşi şekillerde sunar. Özel tubi fibra carbonio tasarımları aşağıdakilerle bile bütünleşir cyclami tpu tüpleri̇ hibrit dayanıklılık için.

Özel şekiller burada gelişir. İhtiyaç fibra de carbono piezas niş bir uygulama için? Otomatik katmanlama teknolojisi kalıpları karbon boşluklar kıvrımlara veya açılara hızlıca. Karbon paneller Lüks iç mekanlardan sağlam makinelere kadar her şeye uyum sağlar. Metallerin aksine karbon paslanmaya ve kimyasallara karşı dayanıklıdır. tubi fibra carbonio zorlu ortamlar için idealdir.

Paslanmaya Dayanıklı, Uzun Ömürlü Yapılar

Metalin aksine, karbon elyaf levha Nem ve kimyasallara karşı güler. Sert iklimlerde paneller yıllarca bozulmadan kalır ve değiştirme maliyetlerini azaltır. Fibra de carbono argentina kullananlar gibi Arjantinli otomobil markaları bu dayanıklılığa yemin ediyor. Artık aşınmış çerçeveler kârınızı azaltmayacak.

Eleştirmenler karbon üretiminin ekosistemlere zarar verdiğini savunuyor. Oysa geri dönüşüm yöntemleri artık 70%'ye kadar atığı geri kazanıyor. Markalar fibra de carbono Arjantin hatta geri dönüştürülmüş elyafları yeni karbon panel stok, hammadde kullanımının azaltılması. Bunu daha uzun ürün ömürleri ile eşleştirdiğinizde, karbon zamanla daha çevreci bir seçim haline gelir.

Güçten Ödün Vermeden Çevre Dostu

Eleştirmenler soruyor: Karbon elyaf sürdürülebilir mi? Modern geri dönüşüm teknolojisi, hurdaları yeni parçalar için karbon boşluklara dönüştürüyor. Daha hafif arabalar da daha az yakıt tüketerek emisyonları azaltıyor. Üretim mükemmel olmasa da, yeşil üretimdeki adımlar panel de carbono'yu eko-rekabetçi kılıyor.

Maliyet bir engel olmaya devam etmektedir. Ham 10 22 karbon fiber ucuz değil, ancak toplu satın alma ve yerel merkezler (Güney Amerikalı tedarikçiler gibi) yardımcı oluyor. Otomatik kürleme fırınları da işçilik süresini kısaltır. Daha küçük partiler için, hidro daldırma yüzeyler fabrikaların kişiselleştirmesine izin verir karbon elyaf levhalar hızlı bir şekilde, maliyetli yeniden üretimden kaçınarak.

Maliyet Zorlukları mı? Çözümler Mevcut

Evet, hammaddeler bütçeleri sarsabilir. Ancak Toray karbon elyafı toplu olarak satın almak veya daha ince 5 mm levhalar masrafları azaltır. Bazı markalar karbon şasi bölümlerini daha ucuz metallerle harmanlayarak maliyet ve performansı dengeliyor. Küçük üretimler için modüler tasarımlar, fabrikaların kalıpları yeniden kullanmasına izin vererek ön yatırımları azaltır.

Karbon çözümlerini benimsemek sadece moda değil, aynı zamanda stratejiktir. Bu konuda uzmanlaşmış yenilikçilerle ortaklık kurmak karbon fiber doku veya siklami TPU tüpler Değişen pazar taleplerine karşı tasarımları geleceğe hazırlar. Stoklama 5mm karbon fiber levha envanter? Aynı anda daha fazla müşteri ihtiyacını karşılamak için kalınlık seçeneklerini çeşitlendirin.

Son Karar: Hız Ölçekle Buluşuyor

Seri üretim karbon fiber tüpler bilim kurgu değil, artık burada. Şık karbon fiber dokulardan sağlam karbon panellere kadar, otomobil üreticileri daha akıllı üretim yapmak için araçlar kazanıyor. İster hız ister sürdürülebilirlik peşinde olun, bu borular bunu sağlıyor. Hattınızı yükseltmeye hazır mısınız? Otomobillerin yuvarlanma şeklini yeniden şekillendiren teknolojiye dalın.

Referanslar:

1.Karbon Fiber Tüplerin Üretim Süreci: Filament Sarma ve Pultrüzyon Arasındaki Farklar

2.Karbon Fiber Tüplerimizle Müşterimizin Ürün Sorunlarını Çözmesine Nasıl Yardımcı Olduk?

3.Drone Teknolojisinde Karbon Fiber Çubuk ve Tüplerin Kullanımı

4.Büyük Çaplı Karbon Fiber Boruların Yüzey Kalitesi Nasıl İyileştirilir?

5.Karbon Fiber Tüp 50mm OD 47mm ID Neden Bu Kadar Popüler?

3 Yanıtları