Breaking the Mold: Carbon Fiber Panel Sheet Repair Explained

The question comes up often: can a carbon fiber panel sheet be repaired? If you’re working with 3mm carbon fiber sheets or larger 4×8 carbon fiber sheet formats, damage happens. From impact cracks to delamination, these high-performance materials aren’t invincible. But assuming replacement is your only option? That’s where misinformation starts.

Common Types of 3mm Carbon Fiber Sheet Damage

Not all carbon fiber panel damage looks the same. Here’s what you might run into:

Cracks or fractures from impact or high stress zones

Delamination from UV exposure or faulty bonding

Surface wear or abrasion, often in high-contact applications

Hole damage from improper drilling or mounting

These issues affect 3mm carbon fiber sheets, carbon fiber sandwich panels, and even carbon fiber honeycomb panels. Knowing what you’re dealing with helps you decide: fix it or ditch it?

The Carbon Fiber Repair Process: What to Expect

Professional carbon fiber panel sheet repair isn’t guesswork. Here’s how it typically unfolds:

Assessment – Identify fiber breakage, delamination, and resin cracking.

Surface Prep – Strip damaged resin, taper sand around break.

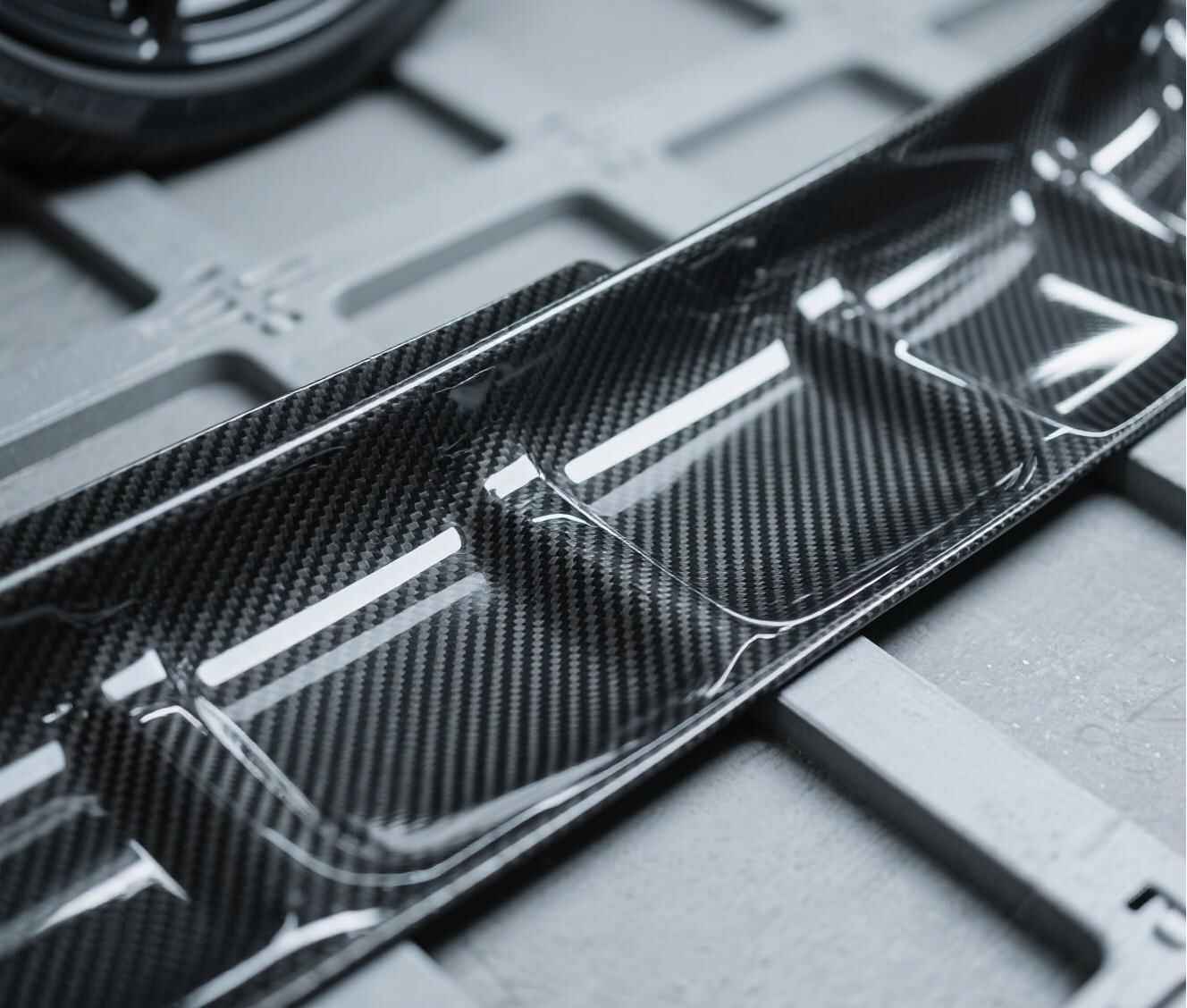

Layup – Apply compatible carbon weave patches with correct fiber direction.

Vacuum Bagging or Pressure Cure – Compress layers to remove air voids.

Curing – Use heat or time, depending on resin system.

Finish Sanding + Seal Coat – Rebuild gloss or matte surface texture.

The result? Your carbon fiber panel sheet regains its shape and performance. Done right, it’s nearly invisible.

References:

1. Top 5 Carbon Fiber Kevlar Sheet Upgrades for Racing Performance

2.How We Helped Our Client Solve Product Issues with Our Carbon Fiber Tubes?

3.Building Your Ultimate Lightweight Drone Frame: A Carbon Fiber Sheets Step-by-Step Guide

4.How to Improve the Surface Quality of Large Diameter Carbon Fiber Tubes

5.How to Modify Custom Carbon Fiber Parts Without Losing Its Strength

Myth #1: Repaired Carbon Fiber Is Weaker Than the Original

This myth spreads fast. Many believe once a carbon fiber panel sheet breaks, its strength vanishes for good. False.

If repaired correctly using matching carbon fiber fabric and high-performance resin systems, a damaged area can recover over 90% of its original strength. That’s not guesswork—it’s backed by aerospace-level testing. For example, properly patched 4×8 carbon fiber sheets used in racing often re-enter competition after localized repair.

Myth #2: Carbon Fiber Cannot Be Repaired

This is flat-out wrong. Carbon fiber repairs have existed for decades. From commercial aviation to sports cars to drones using 3mm carbon fiber sheets, repairs happen daily.

While it’s true that repairs require precision, the idea that carbon fiber is unfixable couldn’t be further from reality. In fact, carbon fiber panels are often easier to fix than some metals because the damage doesn’t propagate as wildly.

Myth #3: DIY Carbon Fiber Repairs Are Just as Good

Not all repairs are created equal. DIY patch jobs may work short-term—but they rarely match the strength, alignment, or resin compatibility of professional work.

Unless you’ve got the right prep tools, vacuum bagging gear, and matched epoxy, a garage fix on your 3mm carbon fiber sheet might peel back under stress. Especially if you’re dealing with structural carbon fiber honeycomb panel components, go pro.

Myth #4: Any Carbon Fiber Damage Requires Full Replacement

This one hurts your wallet more than your project. Many suppliers push full replacements when only a corner or edge of your carbon fiber panel sheet took a hit.

Truth is, if the damage doesn’t extend across multiple fiber directions or affect load-bearing geometry, a partial repair is often possible. Carbon fiber sandwich panel skins or localized fractures in carbon fiber sheets 4×8 can usually be fixed with strategic reinforcement.

Myth #5: Composites Are Too Tricky to Work With

Composites might seem exotic, but carbon fiber repair techniques are getting faster, cheaper, and more user-friendly. Especially with new fast-cure epoxies, repair times are dropping.

Yes, fiber orientation matters. Sure, you’ll need to understand resin compatibility. But with proper guidance, even hobbyists using 3mm carbon fiber sheet can manage minor fixes with confidence.

When Should Carbon Fiber Be Repaired vs. Replaced?

Not every damaged panel can be salvaged. Use these guidelines:

Choose Repair when:

Damage is superficial or limited to one layer

You see no core crush in sandwich panels

Structure still holds shape

Choose Replacement when:

Multiple layers or weaves are torn

Core delamination spreads across a large area

Heat or chemical exposure ruins resin matrix

Carbon fiber honeycomb panels and 4×8 carbon fiber sheets used in aerospace or structural frames often demand tighter tolerances, so use caution when evaluating.

Environmental Benefits of Repairing Carbon Fiber

Carbon fiber doesn’t recycle easily. Landfills hate it. Manufacturing virgin carbon fiber panel sheets takes energy—lots of it.

Repairing instead of replacing cuts emissions, conserves resources, and slashes waste. For companies using 3mm carbon fiber sheets in volume, repair practices can align with sustainability goals while saving serious cash.

The Future of Carbon Fiber Repair Technologies

Repair tech isn’t standing still. Self-healing polymers, rapid-curing epoxy systems, and portable laser scanners are changing the game.

Imagine scanning your carbon fiber panel damage with a phone, receiving repair plans via AI, then curing a patch with a hand-held UV light. Not science fiction—just next-gen repair.

Companies producing 4×8 carbon fiber sheets and carbon fiber sandwich panels are already investing in advanced diagnostics and nano-repair gels. Expect faster turnaround and fewer throwaways.

Final Thought: Don’t Ditch Your Carbon Fiber Panel Sheet Yet

Too many carbon fiber sheets 4×8 get junked over fear, myths, or plain bad info. Understanding repair options gives you power.

If your 3mm carbon fiber sheet cracked during transit or your carbon fiber honeycomb panel saw a corner delaminate, think before tossing. There might be life left—strong, safe, and sustainable.

One Response