اعثر على الشركة المصنعة الموثوق بها لقطع غيار ألياف الكربون باستخدام الحاسب الآلي

أعلى المواد الخام

تُصنع جميع أجزاء كاربون كور ديناميكيات ألياف الكربون باستخدام الحاسب الآلي من صفائح أو أنابيب الكربون المنتجة ذاتيًا، وبالتالي، يمكن التحكم في الجودة، كما سيتم توفير السعر للعملاء.

فريق تقني ماهر

فريق من الفنيين المهرة على مدار 12 عامًا في مجال المواد المركبة، الذين يقدمون تصميمًا ورسمًا إبداعيًا مجانًا مجانًا، ويعالجون الأجزاء النهائية باستخدام الحاسب الآلي بكفاءة واتساق.

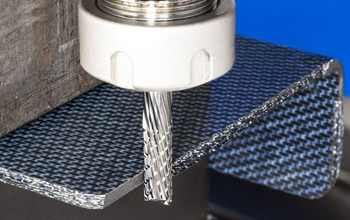

ماكينة CNC دقيقة التحكم الآلي باستخدام الحاسب الآلي

لضمان التصنيع الدقيق والموثوق للمكونات دون المساس بالجودة، فإن ماكينات التحكم الرقمي باستخدام الحاسب الآلي التي قمنا بتجهيزها دقيقة للغاية وكبيرة بما يكفي للقطع الكبيرة.

تحميل الرسم

قم بتحميل الرسم الخاص بك واترك رسالتك عبر الإنترنت أو اتصل بنا عبر البريد الإلكتروني أو الهاتف، فنحن قادرون على تحليل وإعطاء الحل المثالي وعرض الأسعار في غضون ساعتين كحد أقصى. <br> يتوفر رسم ثنائي الأبعاد وثلاثي الأبعاد.

ليس لديك الرسم بعد؟ شاركنا فكرتك، وسيقوم المتخصصون لدينا بإنشاء التصميم المثالي لمشروعك.

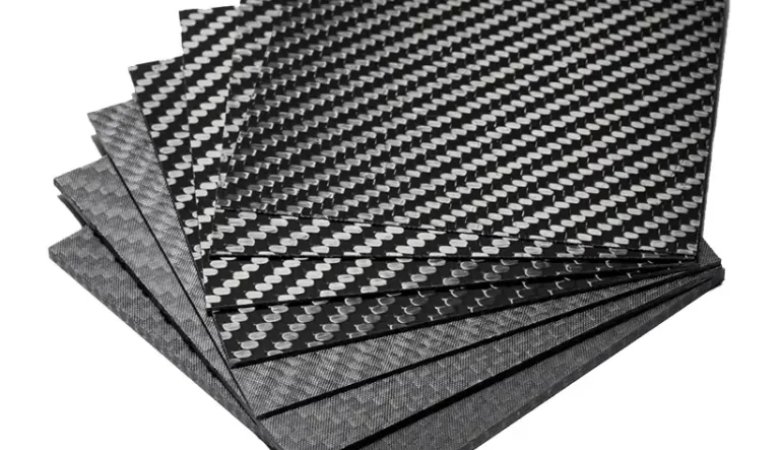

نسج

تقدم التطبيقات المتنوعة متطلبات فريدة من نوعها لألياف الكربون. ولتلبية هذه المتطلبات، تطورت تكنولوجيا نسج ألياف الكربون باستمرار، مما أدى إلى ظهور مجموعة متنوعة من أنماط النسيج.

- نسج قماش قطني طويل

- نسج عادي

- UD (أحادي الاتجاه)

تشطيب السطح

بالنسبة للتفضيلات الجمالية المختلفة واحتياجات التطبيق، يمكن تخصيص تشطيب السطح وفقًا لمتطلباتك.

- لامع

- شبه لامع

- ماتي

قاطرات ألياف الكربون

يمثل الحرف "K" ألف ويستخدم للإشارة إلى عدد الألياف في كل حزمة. كلما زاد العدد، كلما كانت الحزمة أوسع، مما يؤدي أيضًا إلى اختلافات في المظهر.

- 1K

- 3 ك (الأكثر شيوعًا)

- 6K

- 12K

درجة قوة ألياف الكربون

نحن ندرك أن التطبيقات المختلفة تتطلب مستويات مختلفة من الأداء. ولهذا السبب نقدم 3 من أكثر درجات ألياف الكربون شيوعًا لتلبية احتياجاتك الخاصة

- T300 (الأكثر شيوعاً)

- T700

- T800

ما هي قطع غيار ألياف الكربون CNC

تمثّل قطع ألياف الكربون بنظام التحكم الرقمي باستخدام الحاسب الآلي مزيجًا متطورًا من المواد المتقدمة والتصنيع الدقيق. فهي تجمع بين خواص ألياف الكربون خفيفة الوزن وفائقة القوة في نفس الوقت مع الدقة المتناهية للتصنيع باستخدام الحاسب الآلي. تلبي هذه المكونات احتياجات صناعات مثل صناعة الطيران والسيارات والمعدات الرياضية وحتى الأجهزة الطبية. ويسعى العملاء إلى الحصول على هذه الحلول بفضل نسبة القوة إلى الوزن التي لا مثيل لها والمتانة الفائقة وقابلية التخصيص.

الفوائد الرئيسية لقطع غيار ألياف الكربون بنظام التحكم الرقمي

خفيفة الوزن لكنها متينة: ألياف الكربون أخف بكثير من المعدن لكنها قوية بشكل لا يصدق. تقلل هذه الميزة من استهلاك الطاقة في المركبات أو الآلات مع الحفاظ على الأداء.

متانة محسّنة: مقاومة للتآكل، والإجهاد، والعوامل البيئية، تضمن قطع ألياف الكربون CNC المقاومة للتآكل، والإجهاد، والعوامل البيئية طول العمر حتى في ظل الظروف القاسية.

دقة استثنائية: يضمن التصنيع الآلي باستخدام الحاسب الآلي أبعادًا دقيقة، مما يتيح تفاوتات دقيقة ضرورية للتطبيقات عالية الأداء.

الجاذبية الجمالية: يضفي المظهر الأنيق والعصري لألياف الكربون مظهراً أنيقاً وعصرياً على المنتجات مما يجعلها تبرز بصرياً.

حلول لتحديات العملاء

أهداف تخفيض الوزن: سيجد العملاء الذين يتطلعون إلى تقليل الوزن دون التضحية بالقوة أن قطع ألياف الكربون CNC مثالية. على سبيل المثال، غالبًا ما يستبدل عشاق السباقات الأجزاء المعدنية لتقليل الوزن الحيوي.

الأداء تحت الضغط: في البيئات الصعبة مثل الفضاء الجوي أو رياضة السيارات، تضمن مقاومة هذه المكونات لدرجات الحرارة العالية والصلابة الموثوقية في البيئات الصعبة مثل الفضاء الجوي أو رياضة السيارات.

احتياجات التخصيص: تقدّر الشركات التي تحتاج إلى قطع مصممة خصيصًا قدرة الماكينات بنظام التحكم الرقمي على التكيف، والتي تدعم التصميمات الفريدة والأشكال الهندسية المعقدة.

اعتبارات التكلفة: على الرغم من أنها في البداية أكثر تكلفة من المواد التقليدية، إلا أن طول عمر الأجزاء المصنوعة من ألياف الكربون وأدائها يبرر الاستثمار. ويجد العملاء أيضاً وفورات محتملة في انخفاض تكاليف الصيانة والتشغيل.

اختيار الشركة المصنعة لقطع غيار ألياف الكربون CNC المناسبة

مسائل الخبرة: ابحث عن الشركات المصنعة ذات الخبرة المثبتة في ألياف الكربون والتصنيع باستخدام الحاسب الآلي. تحقق من الملفات الشخصية ومراجعات العملاء للتحقق من مصداقيتهم.

أحدث ما توصلت إليه التكنولوجيا: سيقدم المصنعون المجهزون بآلات التحكم الرقمي باستخدام الحاسب الآلي المتقدمة وتقنيات القطع المتطورة نتائج دقيقة.

ضمان جودة المواد: تأكد من أن الشركة المصنعة تستخدم ألياف الكربون عالية الجودة وتتبع معايير صارمة لمراقبة الجودة لضمان نتائج متسقة.

حلول مخصصة: يجب أن تقدم الشركة المصنعة الموثوق بها خدمات مخصصة تلبي متطلبات العملاء الفريدة.

التواصل المتجاوب: يشير التواصل الشفاف والسريع إلى تفاني الشركة المصنعة في إرضاء العملاء.

تفتح قطع التصنيع باستخدام الحاسب الآلي المصنوعة من ألياف الكربون إمكانيات لا حصر لها للعملاء الذين يبحثون عن حلول خفيفة الوزن ومتينة وعالية الأداء. من تقليل استهلاك الطاقة إلى تحسين جماليات المنتج، فإن الفوائد التي تعود على العملاء هي فوائد تحويلية. يمكن للعملاء الاستفادة من هذه الابتكارات للارتقاء بمشاريعهم من خلال مواجهة التحديات بحلول مصممة خصيصًا والشراكة مع مصنعين ماهرين. هل أنت مستعد لتجربة ثورة ألياف الكربون؟ تواصل مع مورد موثوق به اليوم.