Jak listy z uhlíkových vláken mění průmysl dronů

The world of drones is rapidly evolving, and the choice of materials plays a pivotal role in this transformation. Among the various materials utilized, listy z uhlíkových vláken have emerged as a game-changer. They offer unparalleled advantages in weight, strength, and versatility, making them the go-to solution for both drone enthusiasts and commercial operators. Let’s dive into how listy z uhlíkových vláken are reshaping the drone landscape and solving critical challenges faced by users.

Why Weight Matters in Drones

In the drone industry, weight isn’t just a technical specification; it defines performance. Lightweight drones are more agile, consume less power, and deliver longer flight times. Heavier drones demand more from their motors and batteries, leading to shorter operational durations and increased wear on components. For hobbyists, this could mean interrupted fun. For professionals, it might mean compromised missions or higher operational costs.

Listy z uhlíkových vláken solve this weight dilemma. These materials are remarkably lightweight yet robust enough to withstand the stresses of flight. Compared to traditional metals like aluminum, carbon fiber weighs significantly less while offering comparable, if not superior, strength. This weight reduction translates directly into improved efficiency, extended range, and better payload capacity, meeting the diverse needs of drone users.

Drone Construction Materials: Limitations of the Old vs. Benefits of the New

The early days of drone manufacturing saw the use of materials like plastic, aluminum, and wood. Plastic is affordable and easy to mold but lacks durability. Aluminum offers strength and rigidity but adds unnecessary heft. Wood, while lightweight, cannot handle the rigors of modern drone applications. These materials served their purpose but fell short as the demand for high-performance drones grew.

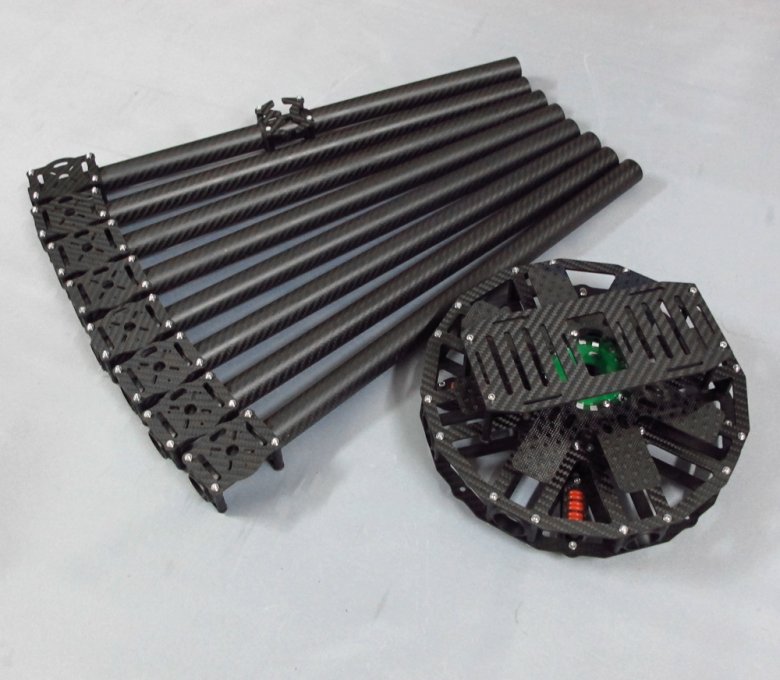

Enter carbon fiber. This advanced material combines the best traits of its predecessors while eliminating their shortcomings. Listy z uhlíkových vláken are resistant to corrosion, tolerate extreme temperatures, and are remarkably strong. Unlike plastic, they won’t crack under pressure. or aluminum, they don’t weigh drones down. Or wood, they offer unmatched consistency and precision for intricate designs. Whether crafting a lightweight racing drone or a heavy-duty industrial UAV, carbon fiber emerges as the ideal choice.

Carbon Fiber for Drone Services: Meeting Real-World Needs

Drone services range from photography and videography to surveying and delivery. Each application places unique demands on drone structures, from carrying delicate cameras to enduring harsh environmental conditions. Listy z uhlíkových vláken rise to the challenge by providing solutions tailored to these diverse needs.

For aerial photography, where stability is crucial, carbon fiber reduces vibrations that can ruin a shot. Surveying drones often operate in challenging terrains. The durability of carbon fiber ensures they survive rough landings or collisions. Delivery drones, which must carry heavier payloads, benefit from the material’s strength-to-weight ratio, allowing them to transport goods efficiently without compromising flight performance.

The Future: Drones Empowered by Carbon Fiber

As the drone industry continues to grow, the reliance on listy z uhlíkových vláken will only increase. This material is not just a component; it’s a cornerstone for innovation. With its ability to address weight, durability, and performance issues, carbon fiber enables drones to achieve new heights, quite literally.

From amateur pilots seeking longer flight times to professionals demanding robust performance under tough conditions, carbon fiber delivers solutions that matter. It transforms limitations into opportunities and enhances what drones can achieve. For anyone involved in the drone ecosystem, embracing carbon fiber is not just an option; it’s the path forward.

Moreover, carbon fiber’s adaptability in design allows manufacturers to create customized solutions. Drone frames, propellers, and mounting brackets crafted from carbon fiber are lightweight and incredibly strong, ensuring reliability in every flight. This material’s capacity for precision engineering also supports the development of cutting-edge drone technologies, from foldable designs to aerodynamic enhancements.