Lastre in fibra di carbonio (fogli in fibra di carbonio in vendita) sono ampiamente utilizzati nel settore aerospaziale, automobilistico e delle attrezzature sportive grazie alla loro leggerezza, elevata resistenza e durata. Che si tratti di un Foglio di fibra di carbonio da 3 mm o uno standard Foglio in fibra di carbonio 4×8Il loro processo di produzione è controllato con precisione. Questo articolo spiega la produzione delle lastre in fibra di carbonio e risponde a domande comuni quali Come tagliare i fogli di fibra di carbonio e dove posso acquistare fogli in fibra di carbonio.

Metodo 1: Processo di produzione delle lastre in fibra di carbonio

1. Preparazione dei precursori

Il processo inizia con un precursore (ad esempio, poliacrilonitrile PAN), che viene carbonizzato per formare fibre di carbonio.

2. Allineamento delle fibre

Le fibre vengono allineate mediante pultrusione per garantire la materiale in fibra di carbonio ha un'elevata resistenza.

3. Tessitura in tessuto di fibra di carbonio

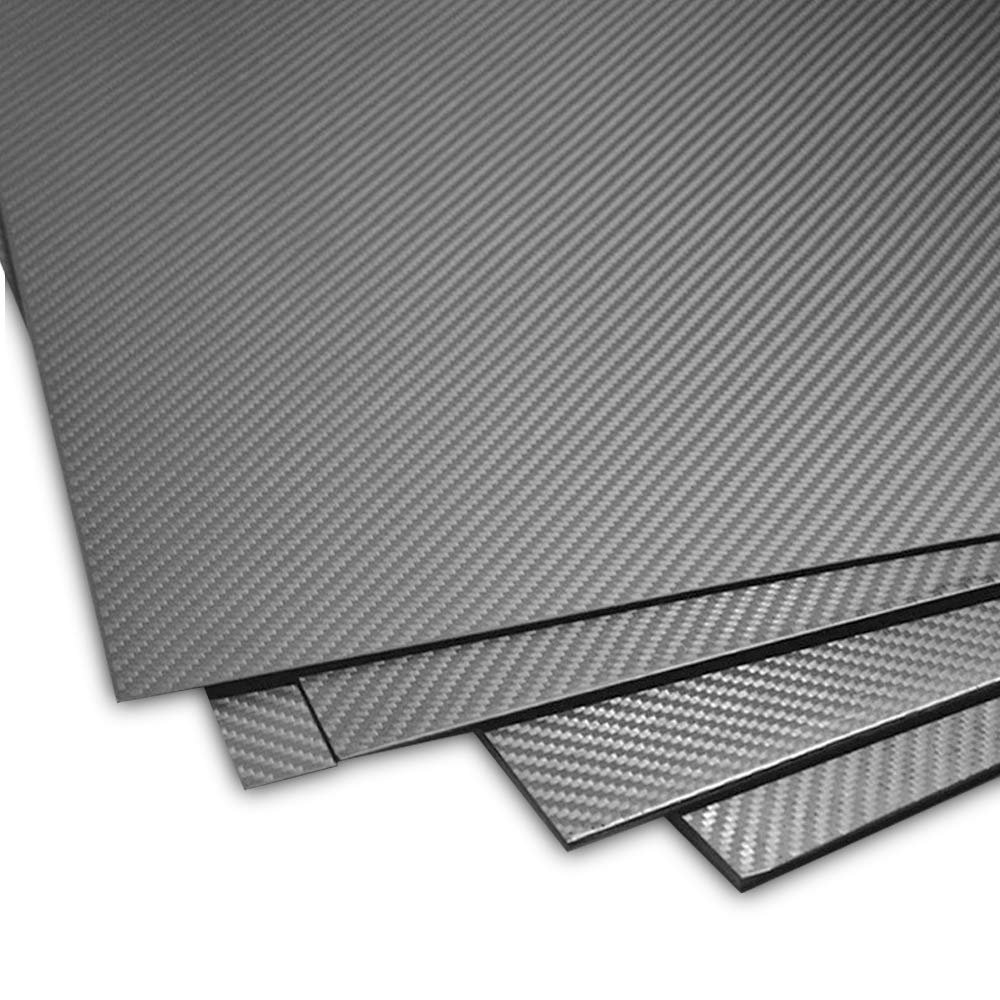

Le fibre vengono tessute in un tessuto (fogli di fibra di carbonio) e termofissare per ottenere una superficie liscia.

4. Impregnazione con resina

Il tessuto è combinato con la resina (fogli di fibra di carbonio e resina) per migliorare la rigidità e la durata.

5. Polimerizzazione a caldo e a pressione

Infine, le lastre vengono polimerizzate ad alta pressione, formando prodotti come foglio in fibra di carbonio 4×8che possono essere tagliati a misura.

Metodo 2: Elaborazione e applicazioni

1. Produzione di fibra di carbonio

Le materie prime vengono stirate a caldo per formare le fibre di carbonio, che costituiscono il fondamento di foglio di fibra di carbonio.

2. Miscelazione e stampaggio della resina

Le fibre di carbonio vengono mescolate con la resina e pressate in stampi per creare dimensioni standard come Foglio in fibra di carbonio 4×8.

3. Trattamento della superficie

Le lastre possono essere rivestite per garantire la resistenza all'acqua o la protezione dai graffi, a seconda delle esigenze applicative.

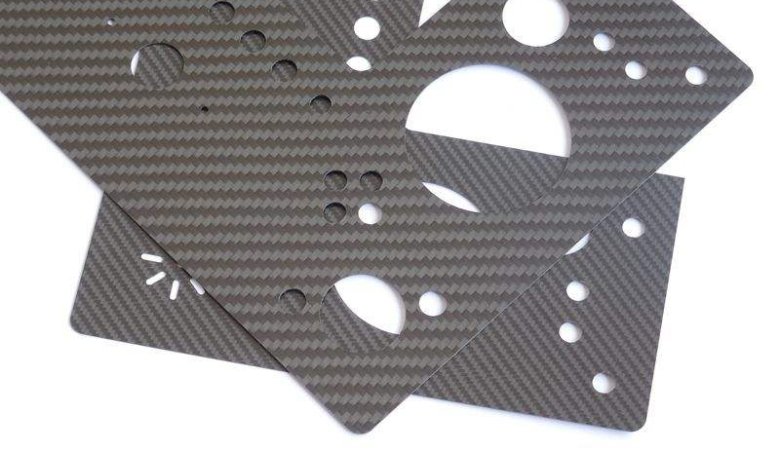

4. Taglio e finitura

Le lastre polimerizzate possono essere tagliate (Come tagliare i fogli di fibra di carbonio) per vari usi industriali o di bricolage.

Dove acquistare i fogli di fibra di carbonio?

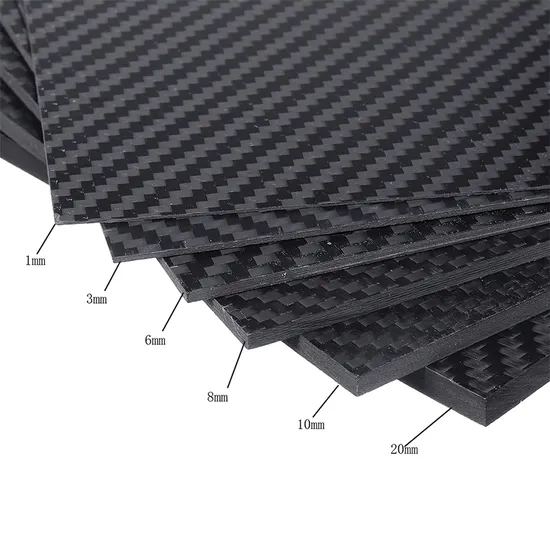

Se si vuole acquistare fogli in fibra di carbonioPer questo motivo, è necessario controllare i fornitori specializzati di compositi o i negozi online (ad esempio, i siti web dei produttori). Le opzioni più comuni includono Foglio di fibra di carbonio da 3 mm e fogli in fibra di carbonio 4×8adatto per l'industria, il fai-da-te e la produzione di prodotti di fascia alta.

Punti di forza:

Realizzato con fibre di plastica riscaldate

La resina aggiunge resistenza e rigidità

Disponibile in taglie come 3 mm e 4×8

Facile da tagliare e personalizzare

Riferimenti:

1.Quanto sono forti le piastre in fibra di carbonio?

2.Come selezionare la giusta lastra in fibra di carbonio per il vostro progetto?

3.Uso di aste e tubi in fibra di carbonio nella tecnologia dei droni

4.Come scegliere le lastre in fibra di carbonio per i droni?

5.Qual è la differenza tra lastre e piastre in fibra di carbonio?

Una risposta