When venturing into the task of selecting carbon fiber tube for drone arms, it’s essential to focus on performance and customization to meet specific needs. This guide explores the advantages of carbon fiber tubing and how bespoke solutions can cater to diverse applications.

Product Performance and Technical Advantages

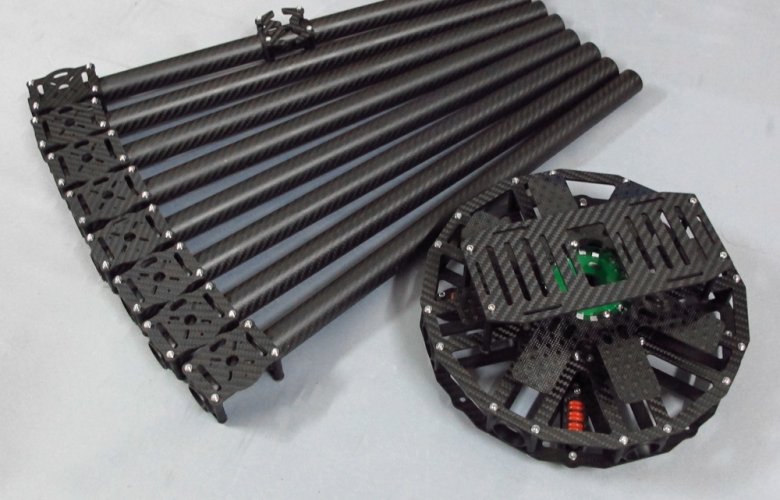

Durability and Strength

Carbon fiber tubing stands out due to its remarkable strength-to-weight ratio. This material is known for its high tensile strength, allowing it to endure substantial loads without bending or breaking. For drone arms, this strength translates into the ability to carry heavier payloads while maintaining structural integrity.

Impact Resistance

In addition to strength, carbon fiber tubing offers excellent impact resistance. Drones often face rough conditions, including hard landings or collisions. Tubes made from carbon fiber absorb shocks and reduce the risk of permanent damage, enhancing the lifespan of the drone components.

Wear Resistance

Wear resistance is another critical factor. Carbon fiber tubing exhibits low wear over time, making it ideal for drone arms that undergo frequent use. This quality ensures that the arms retain their shape and performance, even after prolonged exposure to environmental stressors.

Ease of Installation

Installation of carbon fiber tubing is relatively straightforward. The material can be easily cut and assembled using basic tools, which simplifies the process of building or repairing drone arms. Its lightweight nature further facilitates handling and assembly, making it a preferred choice for hobbyists and professionals alike.

Low Maintenance Costs

Maintenance is a significant consideration for any drone enthusiast or operator. Carbon fiber tubing requires minimal upkeep due to its resistance to corrosion and wear. This characteristic results in lower maintenance costs over the life of the drone, offering a cost-effective solution for long-term use.

Customized Solutions

Tailored Designs for Specific Needs

Different drones serve various purposes, from aerial photography to industrial inspections. As such, the requirements for drone arms can vary widely. Customized carbon fiber tubing solutions allow for specific designs that cater to the unique demands of each application. Whether it’s a particular length, diameter, or wall thickness, custom tubing can be crafted to fit exact specifications.

Industry-Specific Applications

Customized carbon fiber tubing finds its application across numerous industries. For instance, in agriculture, drones equipped with specialized arms can carry sensors for monitoring crops. In the film industry, lightweight and durable arms support high-quality cameras for aerial shots. These examples highlight the versatility of carbon fiber tubing in adapting to diverse operational needs.

Case Studies

Consider a commercial drone manufacturer that required lightweight yet strong arms for a new model designed for search and rescue operations. By opting for customized carbon fiber tubing, they achieved a balance between strength and weight, enabling the drone to carry necessary equipment while maintaining agility. This solution not only met their design criteria but also improved the drone’s overall performance.

Another case involves a drone used for environmental monitoring in harsh conditions. Custom carbon fiber tubing provided the necessary durability to withstand extreme temperatures and humidity, ensuring reliable performance throughout prolonged missions.

結論

Choosing the right carbon fiber tubing for drone arms involves understanding the performance benefits and exploring customized options. By focusing on durability, impact resistance, and ease of installation, users can enhance their drone’s functionality. Additionally, custom solutions ensure that the tubing meets specific operational needs, making carbon fiber an ideal material for a variety of applications. Whether for hobbyist projects or professional endeavors, carbon fiber tubing offers a robust, versatile, and cost-effective solution.