Een 3 mm koolstofvezelplaat often feels simple at first glance. Dark weave. Smooth face. Light weight. However problems appear fast after cutting drilling or loading. Many buyers later discover a plastic laminate fiberglass board or decorative carbon wrap hiding underneath. Therefore learning clear ways for identifying genuine carbon fiber sheet saves money time and failed projects. This guide focuses on visual checks touch tests weight clues and small home experiments that real customers can perform without lab tools. Each method favors simple logic over marketing claims. Meanwhile solutions remain practical rather than technical jargon.

Carbon fiber sheet demand keeps rising across furniture drones robotics automotive panels and hobby builds. Consequently fake look-alikes spread quickly through marketplaces. Some copies look convincing online yet behave poorly in real use. Cracks appear. Edges fray. Strength feels wrong. Therefore early detection matters more than brand names. This article breaks down reliable signs so buyers choose correctly before orders ship.

Referenties:

1. De ideale koolstofvezel voor drones: Bladen Materialen en Opties

2. Hoe koolstofvezelbuis snijden?

3. Inzicht in hardheids- en samendrukkingsproeven van koolstofvezelbuizen

4. Koolstofvezel vs. grafieten hengel: Welke past het beste bij jouw behoeften

5. 8 fouten die ingenieurs maken bij het kiezen van koolstofvezelbuis en hoe ze deze kunnen vermijden

Visual Identification Guide for Genuine 3mm Carbon Fiber Sheet

Visual inspection gives first warnings when checking a 3 mm koolstofvezelplaat. Although photos mislead screens never show depth correctly. Real carbon weave shows order yet never perfect symmetry.

Carbon Fiber Weave Pattern Consistency Check

First observe weave alignment under angled light. Genuine carbon fiber cloth follows predictable twill or plain patterns. Lines run clean yet small distortions appear near edges. Fake sheets often show printed graphics repeating too evenly. Therefore look for tiny inconsistencies that machines rarely fake well.

Additionally real carbon fiber weave shifts slightly when light moves. Printed film stays flat visually. That light response offers a fast tell even before touching surface.

Surface Depth and Resin Reflection Test

Next watch reflection behavior. Real carbon fiber resin creates layered depth. Shine a phone light across panel face. You should see subtle shadowing between fiber bundles. Plastic laminates reflect like mirrors without depth variation.

Furthermore resin thickness feels uneven microscopically. Perfect glass-like flatness often signals imitation.

Touch and Tap Tests for 3mm Carbon Fiber Sheet Authenticity

Hands reveal truth faster than spec sheets. Touch tests expose hidden structure quickly.

Temperature Response and Feel

Carbon fiber conducts heat differently than plastic. Place palm flat for several seconds. Genuine carbon fiber sheet pulls warmth away faster. Plastic stays neutral longer. Therefore temperature response matters more than finish gloss.

Additionally carbon fiber surface feels dry not waxy. Laminated films often feel slick.

Tap Sound and Vibration Behavior

Tap panel edge using knuckle or coin. Authentic carbon fiber emits sharp crisp tone. Plastic boards sound dull or hollow. Meanwhile fiberglass sheets produce softer muted resonance.

Try tapping near corners and center. Real carbon fiber stays consistent across panel. Fake layers often vary sound location by location.

Weight Edge and Underside Inspection for Carbon Fiber Sheets

Weight never lies. Marketing exaggerates. Scales stay honest.

Density Comparison for 3mm Carbon Fiber Sheet

Weigh known dimensions using kitchen scale. Genuine 3 mm koolstofvezelplaat weighs noticeably less than fiberglass panels of equal size. Plastic laminate cores feel heavier than expected for thickness.

Therefore compare weight against supplier specs. Large deviation often signals fake core materials.

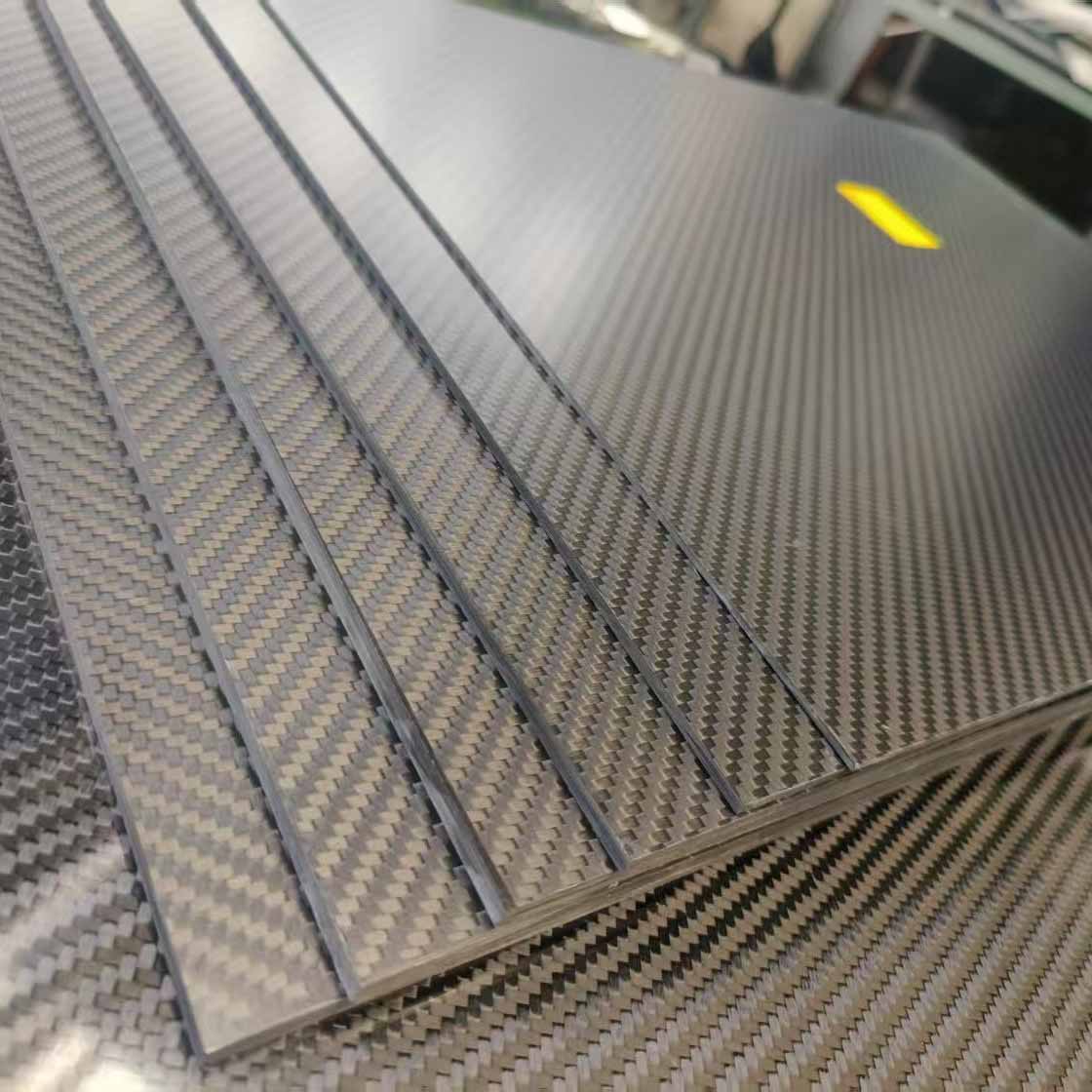

Edge Fiber Exposure Test

Inspect cut edge closely. Real carbon fiber reveals dark layered fibers embedded through entire thickness. Fake boards show thin decorative layer bonded over lighter substrate.

Run fingernail across edge. If fiber stops after top skin thickness suspicion rises immediately.

Underside Surface Matching

Flip sheet over. Real carbon fiber often shows similar weave pattern on backside unless surface treatment differs. Decorative carbon film typically appears only one side.

Backside color variation also matters. Pure resin underside looks consistent not chalky.

DIY Scientific Checks for Genuine Carbon Fiber Sheet at Home

No lab required. Simple physics helps.

Water Drop Absorption Behavior

Place single water drop on surface. Genuine cured resin repels water strongly. Drop beads tightly. Fake laminate may spread slightly over time.

Wipe drop after thirty seconds. Residue rings indicate surface coatings rather than structural resin.

UV Light Reaction Test

Shine UV flashlight if available. Carbon fiber resin shows minimal fluorescence. Many plastics glow faint blue or green. Although not perfect this method adds confidence when combined with others.

Flex Resistance Comparison

Apply light bending force across unsupported span. Real carbon fiber resists flex strongly even thin panels. Plastic cores flex easily before rebound.

Do not overbend. Gentle pressure reveals stiffness difference safely.

Common Fake Carbon Fiber Look-Alikes and How to Spot Them

Understanding impostors speeds detection.

Carbon Fiber Vinyl Wrapped Panels

Vinyl wrap fools cameras not hands. Surface feels rubbery. Edges peel under pressure. Weight feels wrong. Sound remains dull.

These products serve decoration not structure.

Fiberglass Sheets with Carbon Print

Fiberglass shares some stiffness yet heavier feel. Edges show white glass strands. Tap sound softer. Weight test exposes difference quickly.

Many sellers label fiberglass boards loosely using carbon buzzwords.

ABS Plastic Carbon Pattern Boards

ABS panels feature molded carbon texture. Pattern repeats exactly. Heat sensitivity appears faster. Structural strength remains low.

Cut edge melts slightly under friction. Carbon fiber never melts.

When Professional Verification Makes Sense

Some projects demand certainty beyond home checks.

Aerospace Drone and Structural Applications

Critical loads require verified material. Request supplier certifications including fiber type resin system cure method and thickness tolerance.

Trusted manufacturers provide data sheets without hesitation.

CNC Machining and Tight Tolerance Builds

CNC cutting reveals internal truth quickly. Fake cores gum cutters. Carbon fiber machines clean with dust not chips.

If machining planned professional confirmation avoids tool damage.

Long-Term Outdoor Use Concerns

UV resistance moisture resistance and fatigue behavior vary widely among composites. Professional testing ensures durability expectations align with application demands.

Buyer Solutions for Avoiding Fake 3mm Carbon Fiber Sheet

Practical steps reduce risk immediately.

Buy from manufacturers not resellers

Ask for raw material photos before finishing

Request cut edge images

Compare listed density values

Avoid vague product descriptions

Additionally build relationship with suppliers who specialize in carbon fiber sheets rather than mixed materials catalogs.

Why Genuine 3mm Carbon Fiber Sheet Costs More Yet Saves Money

Cheap panels fail faster. Cracks warp and delaminate under load. Replacement costs exceed upfront savings. Genuine carbon fiber delivers predictable stiffness fatigue resistance and machining stability.

Therefore investment pays back through performance reliability and reduced rework.

Summary: Simple Checks Prevent Costly Carbon Fiber Mistakes

Identifying real 3 mm koolstofvezelplaat never relies on single test. Visual depth touch sound weight edges and small experiments combine into reliable judgment. Fake look-alikes exploit appearance not structure. Meanwhile real carbon fiber behaves consistently across every test.

Smart buyers trust hands eyes and logic more than labels.