Introduction: Choosing the Right Carbon Fiber Tube

Selecting a carbon fiber tube for engineering or product design feels simple at first glance, yet the choice between pultruded and roll-wrapped can make or break a project. Engineers weighing a carbon fiber round tube, a carbon fiber rectangular tube, or even a square carbon fiber tube often ask one central question: which process delivers the right balance of strength, geometry, and cost? Understanding the differences in how these tubes are created will help you avoid mismatches that lead to wasted budget or underperforming parts.

What Pultruded and Roll-Wrapped Processes Actually Are

Pultrusion resembles extrusion in concept. Continuous fibers get pulled through a resin bath then drawn into a heated die, forming a consistent profile like a 1 carbon fiber tube or even long beams. This method creates uniformity across the length, making it efficient for high-volume runs.

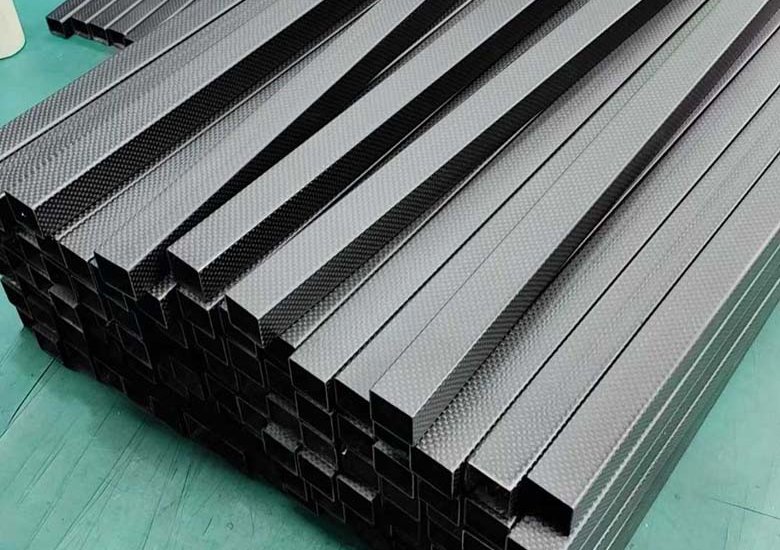

Roll-wrapping works differently. Sheets of pre-impregnated carbon fiber fabric are wrapped around a mandrel, compacted under pressure, then cured. The method offers more freedom with fiber orientation, allowing precise tuning of stiffness and strength. This versatility explains why high-performance industries lean toward roll-wrapped parts.

How Pultruded and Roll-Wrapped Carbon Fiber Differ Mechanically

Mechanically, pultruded tubes shine in straight axial strength. Fibers running parallel through the length deliver incredible rigidity under tension or compression. However, lateral impact or twisting motion exposes their weak side.

Roll-wrapped tubes behave more like engineered composites. Because the fibers can be laid at varied angles, they absorb torque, bending, and cross-loading more gracefully. This makes them popular for applications where loads are multidirectional, like in drones or automotive suspension.

Pultruded Carbon Fiber vs Roll-Wrapped: Cost and Volume

Pultrusion dominates cost-sensitive, high-volume production. A pultruded carbon fiber tube can be made quickly, consistently, and with little scrap. For industries producing thousands of identical shafts or beams, this advantage is huge.

Roll-wrapped tubes demand more labor and time. Although slower, they produce premium-quality results, often required where performance metrics justify the extra spend. For prototypes or low-run specialty builds, the added cost is usually worth the tradeoff.

References:

1. The Ideal Carbon Fibre for Drones: Sheets Materials and Options

2. How to Cut Carbon Fiber Tube?

3. Understanding the Hardness and Compression Testing of Carbon Fiber Tubes

4. Carbon Fiber vs. Graphite Rod: Which One Fits Your Needs Best

5. 8 Mistakes Engineers Make When Choosing Carbon Fiber Tube and How to Avoid Them

Performance and Quality: Where Roll-Wrapping Wins

Roll-wrapped tubes deliver superior mechanical balance. A 1.5 inch carbon fiber tube produced this way will resist torsion better than its pultruded twin. Even large-format components, such as a 4 inch carbon fiber tube, can achieve high performance thanks to fiber angle flexibility.

Engineers chasing lightweight precision often pick roll-wrapped geometry. Bicycles, aerospace braces, and robotics arms frequently rely on this process since performance failures would cost more than material expense.

Geometry Limits and Design Freedom

Roll-wrapping limits shape variety. Straight, uniform profiles like round tubes work well. Yet, once you ask for a carbon fiber rectangular tube or complex taper, roll-wrapping quickly shows its boundaries.

Pultrusion allows variable thickness, or odd-shaped geometries. This freedom enables a square carbon fiber tube with angled plies for specialized mechanical behavior, something roll-wrapping cannot easily replicate.

Typical Use Cases and Decision Rules

Pultruded carbon fiber: ideal for structural beams, spars, or simple shafts where cost matters more than complex load management.

Roll-wrapped carbon fiber: preferred for sports gear, aerospace braces, UAV arms, and automotive components where multidirectional forces act.

Carbon fiber round: often comes in both forms, selected based on whether torsional resistance or raw axial strength is the priority.

As a simple rule, choose pultrusion when repeatability and price dominate. Pick roll-wraps when mechanical nuance and durability matter more.

Practical Compromises and Hybrid Approaches

Not every project needs to pick only one. Some manufacturers combine pultruded cores with roll-wrapped outer layers, giving strength in one axis while protecting against torsion. This hybrid approach can cut cost while delivering better performance than pultrusion alone.

For instance, a 1 carbon fiber tube with pultruded strength and a roll-wrapped surface layer may hit a sweet spot in drone manufacturing. The balance reduces material waste and offers engineers flexibility without breaking budgets.

Testing and Specification Tips

Customers often overlook proper testing. Specifying only dimensions like “1.5 inch carbon fiber tube” does not guarantee performance fit. Always check datasheets for tensile modulus, torsional stiffness, and impact strength. Small test samples reveal how a 4 inch carbon fiber tube will behave before scaling into full production.

Including standardized testing in sourcing helps avoid costly surprises later. When in doubt, request prototype samples and compare real-world performance before committing to volume.

Final Recommendation: Which Carbon Fiber is Better?

So, which carbon fiber option deserves your pick?

- If your project needs thousands of uniform shafts where price leads the decision, go pultruded.

- If your system faces twisting loads, vibration, roll-wrapped makes more sense.

Engineers often find themselves balancing budget, mechanical demand, and timeline. The smart move is to align the tube form—pultruded or roll-wrapped—with the true stress conditions. That alignment ensures your carbon fiber tube not only fits but thrives in its role.