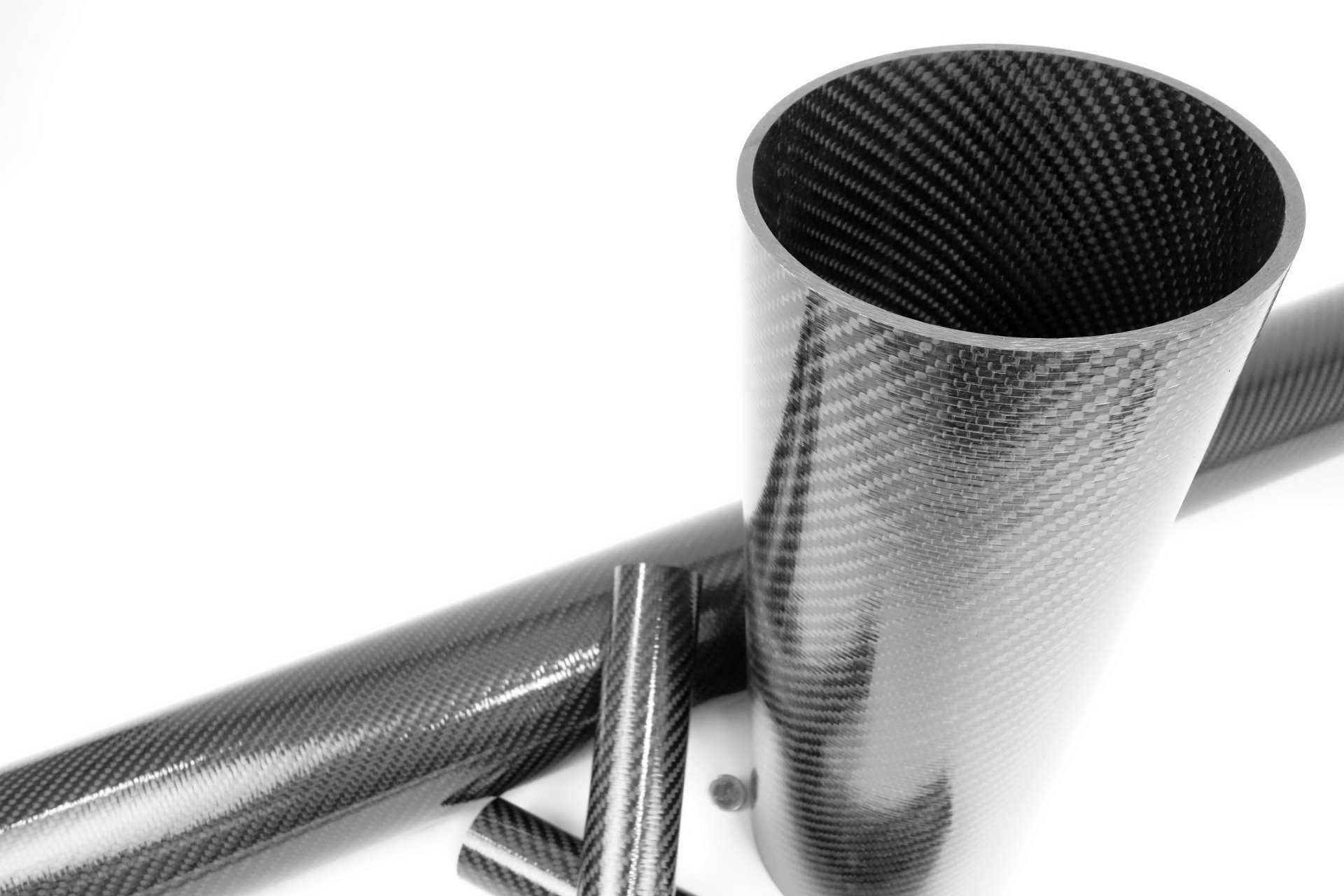

When working with large diameter carbon fiber tubes, achieving a smooth, flawless surface is crucial. Whether you’re crafting a carbon fiber air intake tube or constructing a carbon fiber tube frame, the final product must not only be strong but also visually appealing. Surface imperfections can hinder both performance and aesthetics, especially for industries relying on high-quality components like aerospace, automotive, or even sports equipment. Here’s a guide on how to improve the surface quality of these tubes.

1. Proper Manufacturing Techniques

Creating carbon fiber tubes requires more than just the right materials. It’s essential to use the correct molding and curing processes to prevent defects. For large diameter carbon fiber tubes, the layup method (how the fibers are layered during the manufacturing process) plays a significant role. Pay attention to the number of layers and the direction of the fibers. Incorrect layups can lead to imperfections like voids or uneven surfaces.

For those interested in how to make carbon fiber intake tubes, you’ll need precise molding techniques to achieve the smoothness necessary for high-performance parts. A smooth outer layer ensures the tube won’t interfere with airflow, especially in applications like air intake systems. The smoother the surface, the better the functionality and aesthetics of the final product.

2. Sanding and Polishing

Sanding is a critical step in enhancing the surface finish of large carbon fiber tubes. After the tubes are cured, they may have rough spots or uneven surfaces. Start with coarse sandpaper and gradually move to finer grits. Sanding not only smooths out the surface but also helps to remove excess resin or any remaining mold release agent.

When it comes to cutting carbon fiber tube, ensure that the cutting process doesn’t create frayed edges. Using specialized saws with fine blades or a water jet cutter can minimize damage to the edges, leading to a cleaner, smoother cut.

3. Using Resin and Gel Coat Layers

After sanding, you may want to apply a gel coat or a resin finishing layer. This is often done when creating carbon fiber square tubes or other structural parts. The resin layer seals the surface, filling in any microscopic imperfections. This step not only improves the visual appeal of the tapered carbon fiber tube but also provides added protection against wear, UV damage, and scratches.

4. Applying a Clear Coat

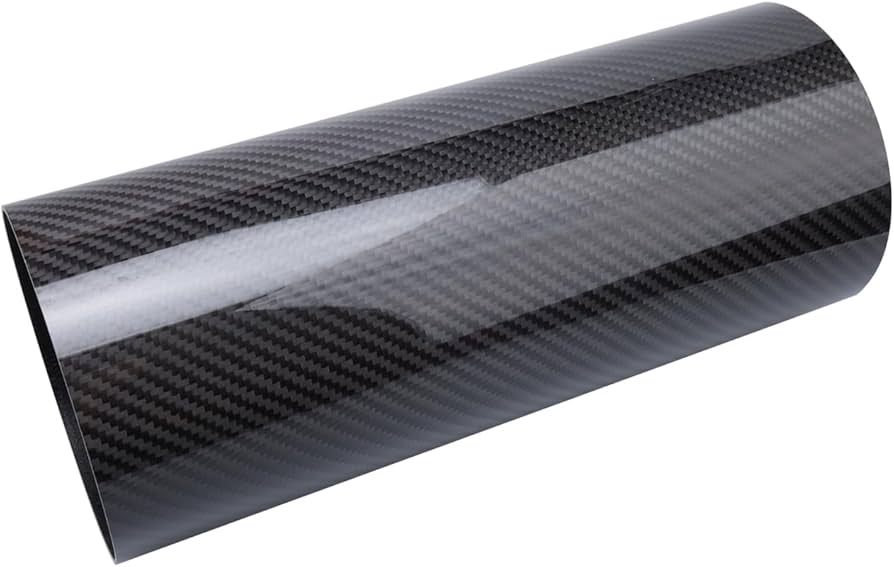

For parts that will be exposed to the elements or require an extra layer of durability, applying a clear coat after sanding and polishing is essential. This is especially crucial for 4 inch carbon fiber tubes used in automotive or aerospace applications where exposure to harsh conditions can quickly degrade unprotected surfaces.

The clear coat also helps in making the tube look more polished and professional. It adds a glossy finish that enhances the tapered carbon fiber tube’s natural texture, creating a high-quality appearance.

5. Carbon Fiber Tube Repair Kits

Even with careful handling, accidents happen. Cracks, chips, or other imperfections can still occur. Fortunately, you can use a carbon fiber tube repair kit to fix these issues without compromising the tube’s integrity. These kits usually include resin, hardener, and patches, allowing you to mend small areas of damage quickly.

When repairing a tube, ensure the repair is smooth and properly sanded after the resin cures. A well-repaired tube will maintain both the strength and surface quality needed for high-performance applications.

6. Advanced Finishing Techniques

For high-end applications, such as carbon fiber tube connectors in engineering projects, additional finishing techniques like vacuum bagging or autoclave curing can be used. These techniques help remove air bubbles and ensure an even distribution of resin, which results in a much smoother surface.

7. Buying Quality Carbon Fiber Tubes

For those not manufacturing their own large diameter carbon fiber tubes, selecting the right supplier can make a big difference. When buying carbon fiber tubes, look for reputable suppliers that offer high-quality products with well-controlled manufacturing processes. This ensures that you’re starting with a tube that already has a better surface finish and fewer imperfections to fix.

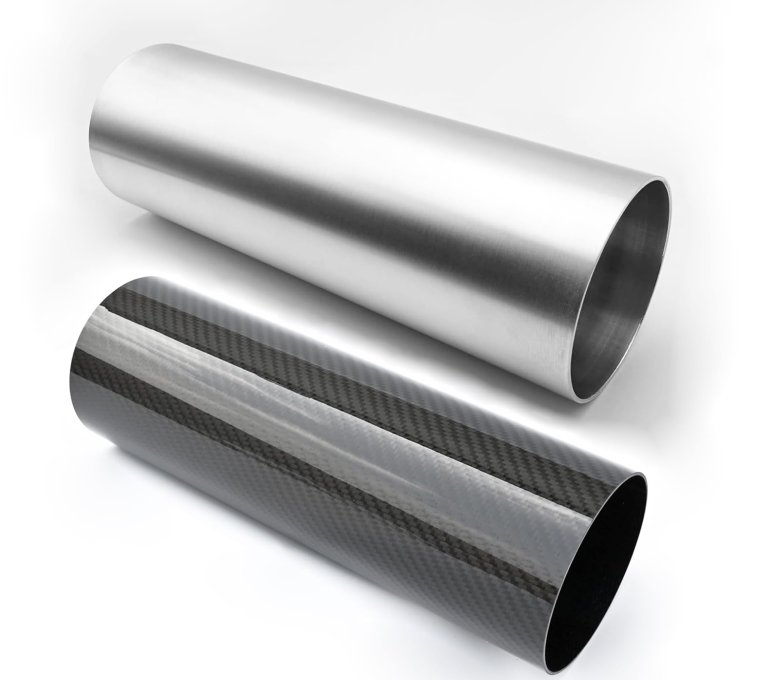

8. Are Carbon Fiber Tubes Much Lighter Than Aluminum?

Yes, tapered carbon fiber tube are significantly lighter than aluminum. This characteristic makes them ideal for industries like aerospace and automotive, where weight reduction is critical. In terms of strength-to-weight ratio, carbon fiber far exceeds aluminum, offering better performance without sacrificing durability.

Conclusion

Improving the surface quality of large diameter carbon fiber tubes isn’t just about aesthetic appeal; it directly impacts performance. Whether you’re cutting carbon fiber tubes for a specific application, making carbon fiber square tubes, or crafting something as specialized as a carbon fiber air intake tube, focusing on quality control during manufacturing and post-production processes ensures the final product meets the highest standards. Remember, from using the right techniques to choosing the best tools and materials, achieving a perfect surface quality is more than possible—it’s essential for creating top-tier components.

References:

1.The Manufacturing Process of Carbon Fiber Tubes: Differences Between Filament Winding and Pultrusion

2.How We Helped Our Client Solve Product Issues with Our Carbon Fiber Tubes?

3.Unlocking the Power of Carbon Fiber Tubing: The Future of Lightweight and Flexible Telescopic Tubes

4.Understanding the Hardness and Compression Testing of Carbon Fiber Tubes

5.Why Is the Carbon Fiber Tube 50mm OD 47mm ID So Popular?

6 Responses