Gücü ve Çok Yönlülüğü Karbon Fiber Plakalar: CarbonCore Dynamics'in Sunduklarına Derinlemesine Bir Bakış

At CarbonCore Dynamicsolarak, çeşitli sektörlerin ihtiyaçlarını karşılamak için özel olarak tasarlanmış çok çeşitli karbon fiber plakalar da dahil olmak üzere yüksek kaliteli karbon fiber ürünler sunma konusunda uzmanız. Olağanüstü güç-ağırlık oranıyla bilinen karbon fiber plakalar, havacılık ve otomotivden spor ve tıbbi cihazlara kadar çeşitli sektörlerde tercih edilen bir malzeme haline gelmiştir. Aşağıda, mevcut boyutlar ve bu malzemeleri tanımlamak için kullanılan diğer terimler de dahil olmak üzere karbon fiber plakaların gücünü ve çeşitli uygulamalarını inceleyeceğiz.

Karbon Fiber Plakalar Nedir?

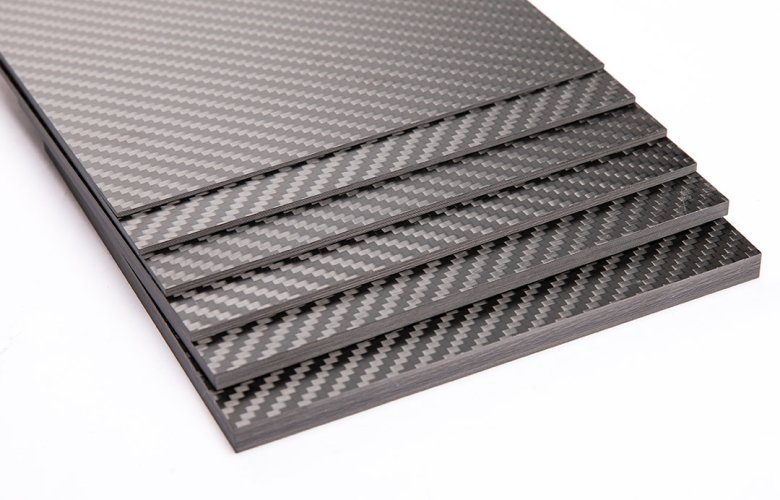

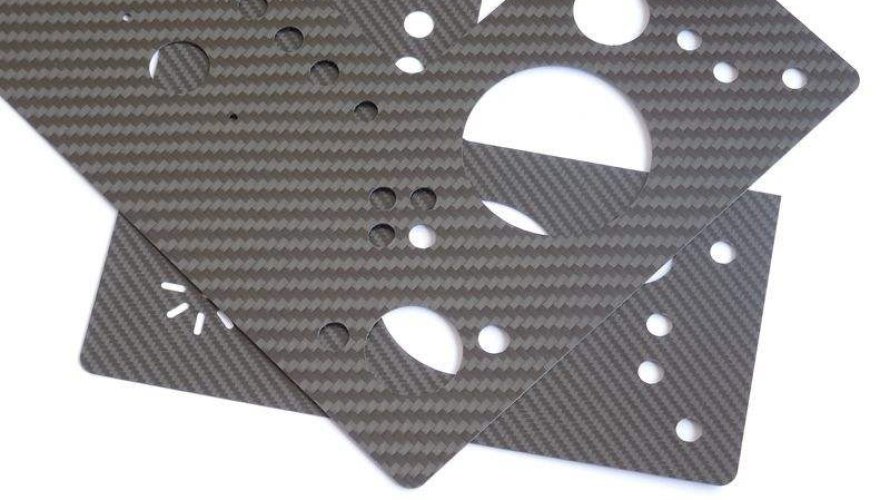

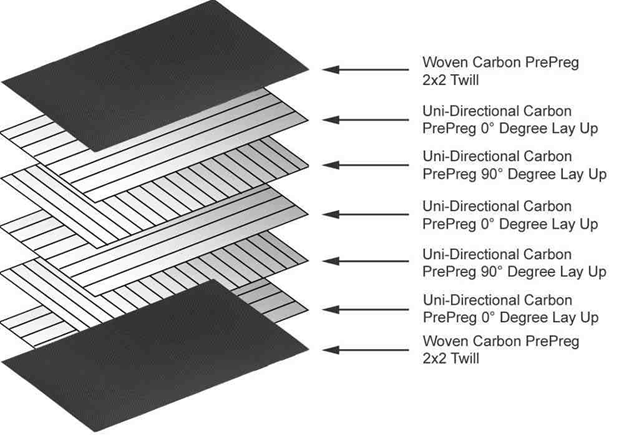

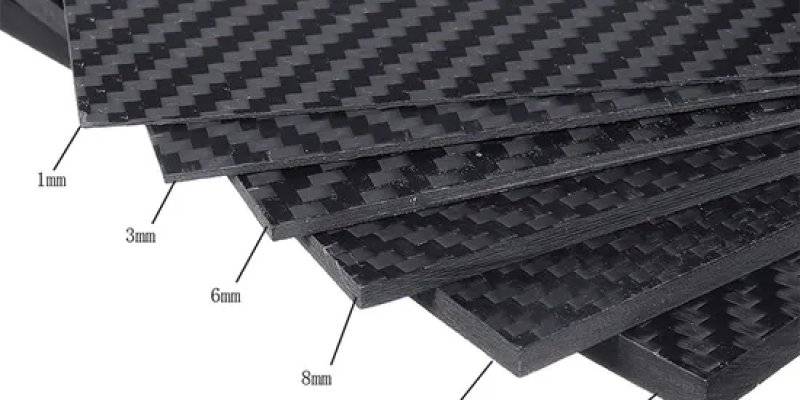

Karbon fiber plakalarveya karbon elyaf levhalarbir reçine matrisi ile birleştirilmiş karbon fiberlerden yapılmış düz, sert panellerdir. Karbon fiber levhaların serilmesi ve reçine ile emprenye edilmesi işlemi, hafif ancak inanılmaz derecede güçlü, sağlam ve dayanıklı bir malzeme oluşturur. Bu plakalar, kullanım amaçlarına bağlı olarak çeşitli kalınlıklarda, boyutlarda ve yüzeylerde gelir ve çok çeşitli uygulamalar için uygundur.

Karbon Fiber Plakaların Yaygın Boyutları

At CarbonCore Dynamicssağlıyoruz karbon fiber plakalar çeşitli standart ve özel boyutlarda, uygulamalarda esneklik sağlar. En yaygın boyutlardan bazıları şunlardır:

- Kalınlık: Mukavemet gereksinimlerine bağlı olarak 0,5 mm ila 50 mm veya daha fazla aralıklar.

- Uzunluk: Tipik olarak 1000 mm (1 metre), 2000 mm (2 metre) ve istek üzerine özel uzunluklarda mevcuttur.

- Genişlik: Standart genişlikler 500 mm, 1000 mm ve 1250 mm'dir, ancak proje özelliklerine göre özel genişlikler üretilebilir.

Karbon Fiber Plakalar için Diğer Terimler

Sektörde, karbon fiber plakalar uygulamaya veya bağlama bağlı olarak birkaç farklı terimle de ifade edilebilir:

- Karbon Fiber Levhalar - Karbon fiber plakaların daha ince bir formu olup, genellikle yüksek esneklik ve daha düşük kalınlık gerektiren uygulamalarda kullanılır.

- Karbon Fiber Laminatlar - Bir plaka oluşturan karbon fiber tabakaların istiflenmiş veya katmanlı bir konfigürasyonu. Laminatlar ek güç ve sertlik sunar.

- Karbon Fiber Paneller - Tipik olarak daha büyük veya daha sert karbon fiber yapılara atıfta bulunan plakalarla birbirinin yerine kullanılır.

- Karbon Fiber Kompozitler - Genel olarak, kompozit bir yapı oluşturmak için elyafları reçine ile birleştiren plakalar da dahil olmak üzere karbon elyaf takviyeli malzemeleri ifade eder.

Bu malzemeler piyasada birbirinin yerine kullanılmaktadır ancak karbon elyafın nasıl işlendiği veya son ürünlerde nasıl kullanıldığı konusunda farklılıklar göstermektedir.

Karbon Fiber Plakaların Uygulamaları

Otomotiv Endüstrisi

Otomotiv endüstrisinde, CarbonCore Dynamics gövde panelleri, kapı çerçeveleri ve yapısal takviyeler gibi otomobil parçalarında kullanılmak üzere karbon fiber plakalar sunmaktadır. Otomotiv üreticileri gücü korurken ağırlığı azaltmayı hedeflediklerinden, karbon fiber açık bir avantaj sağlar. Karbon fiberden yapılan parçalar sadece daha hafif olmakla kalmaz, aynı zamanda deformasyona karşı daha dayanıklıdır, bu da onları spor arabalar, lüks araçlar ve yarış arabaları için ideal hale getirir.

Havacılık ve Uzay Endüstrisi

Havacılık ve uzay sektörü, mükemmel mukavemet/ağırlık oranı nedeniyle karbon fiber plakaları uzun süredir benimsemiştir. Karbon fiber paneller uçak gövdesi bölümlerinin, kanat sparlarının ve iç bileşenlerin yapımında kullanılır. At CarbonCore Dynamicskarbon fiber plakalarımız kritik havacılık uygulamaları için özel olarak tasarlanmıştır ve yakıt verimliliği ve performansın anahtarı olan ağırlığı azaltırken üstün dayanıklılık sağlar.

Spor ve Tıbbi Ekipmanlar

Karbon fiber plakalardan yararlanan bir diğer önemli sektör de spor ekipmanlarıdır. CarbonCore Dynamics, hem güç hem de düşük ağırlık ihtiyacının çok önemli olduğu bisikletlerde, kaykaylarda ve snowboardlarda kullanılan karbon fiber plakalar sağlar. Ayrıca, ortez destekleri ve protezler gibi tıbbi cihazlar da gereksiz ağırlık eklemeden güç ve esneklik sağladıkları için karbon fiber plakaları kullanmaktadır.

Karbon Fiber Plakalar Ne Kadar Güçlüdür?

Karbon fiber plakaların mukavemeti birkaç temel özellik kullanılarak ölçülebilir:

- Elastisite Modülü - Bu, malzemenin sertliğini ifade eder ve elastik bölgesindeki gerilme ve gerinim arasındaki ilişkiyi gösterir.

- Nihai Çekme Dayanımı - Bu, malzemenin kırılmadan önce dayanabileceği maksimum gerilimi gösterir.

- Yoğunluk - Birim hacim başına kütlenin bir ölçüsü olan karbon fiberin çelik gibi malzemelere kıyasla daha düşük yoğunluğu, onu hafif bileşenler gerektiren uygulamalar için ideal hale getirir.

- Spesifik Sertlik ve Spesifik Çekme Dayanımı - Bu iki özellik, farklı yoğunluklara sahip malzemeleri karşılaştırırken çok önemlidir. Karbon fiber, birim kütle başına hem sertlik hem de gerilme mukavemeti açısından alüminyum ve çelik gibi metallerden tipik olarak daha iyi performans gösterir.

Karbon fiber plakalar şu özellikleriyle bilinir yüksek mukavemet/ağırlık oranıBu da alüminyumun neredeyse 4 katıdır. Bu da karbon elyafı, hem mukavemetin hem de ağırlığın kritik olduğu havacılık, otomotiv yarışları ve yüksek performanslı mühendislik gibi alanlarda ideal bir malzeme haline getirmektedir.

Karbon Fiberin Çelik ve Alüminyum ile Karşılaştırılması

Karbon fiber özellikle hem çelik hem de alüminyumdan daha güçlü ve daha hafif:

- Çelik hakkında 5 kat daha yoğun karbon fiberden daha ağırdır, bu da aynı hacim için çok daha ağır olmasını sağlar. Çelik güçlü olsa da, ağırlık söz konusu olduğunda çok daha az verimlidir.

- Alüminyum çelikten daha hafiftir, ancak karbon elyafın güç/ağırlık oranı hala alüminyumun neredeyse iki katıdırBu da onu performansın öncelikli olduğu durumlarda üstün bir malzeme haline getirir.

Sonuç

Sonuç olarak, CarbonCore Dynamics çeşitli sektörlerin ihtiyaçlarını karşılamak üzere tasarlanmış çok çeşitli yüksek kaliteli karbon fiber plakalar sunmaktan gurur duyar. İster otomotiv, havacılık, medikal veya spor malzemeleri sektöründe olun, karbon fiber plakalarımız güç, dayanıklılık ve hafif performansın mükemmel kombinasyonunu sağlar. Özel boyutlar ve kalınlıklar ile özel gereksinimlerinizi karşılayabilir ve projeniz için doğru malzemeyi almanızı sağlayabiliriz.

Bugün karbon fiber ürün yelpazemizi keşfedin ve mevcut en güçlü, en hafif malzemelerden biriyle çalışmanın avantajlarını keşfedin.

Bir Yanıt