Comment choisir le meilleur tube en fibre de carbone pour une application ?

Lors de la sélection d'un carbon fibre tube, ensuring compatibility with your project’s needs is crucial. Missteps in this process can lead to inefficiencies, performance issues, or even structural failures. By understanding the different types of tubes en fibre de carbone, delving into mechanical testing, and interpreting critical results, you can make an informed decision tailored to your application. Below, we explore key factors to help you choose wisely.

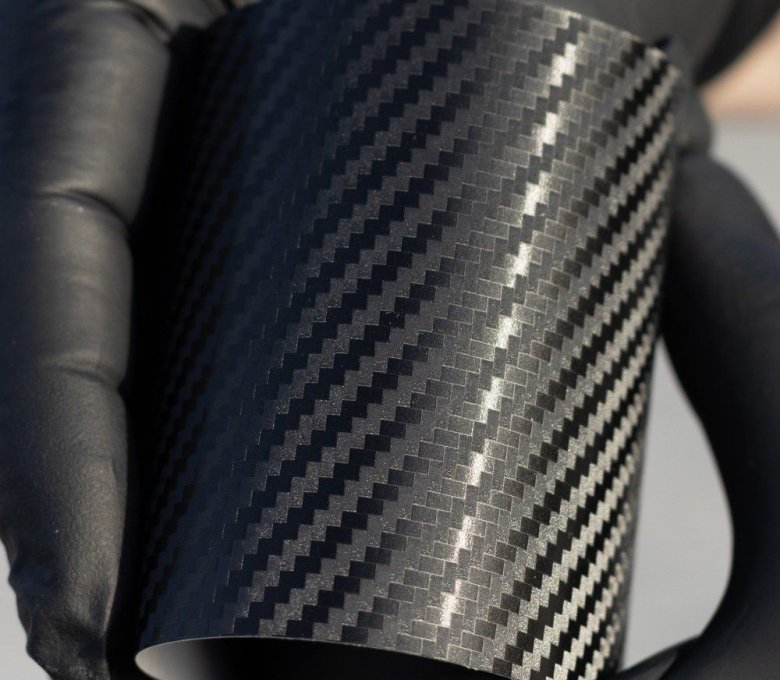

1. The Different Types of Carbon Fibre Tube

Carbon fibre tubes come in various forms, each designed for specific use cases. Pultruded tubes are ideal for applications requiring cost-efficiency but lack multi-directional strength. Filament-wound tubes are robust, offering excellent resistance to torsional loads, making them perfect for dynamic environments. Roll-wrapped tubes, on the other hand, strike a balance between lightweight construction and superior strength in multiple directions. Your choice depends on whether stiffness, flexibility, or weight savings matter most in your project.

2. Mechanical Testing Introduction

Mechanical testing is essential to evaluate a carbon fibre tube’s performance under stress. It reveals how the material will behave in real-world conditions, ensuring reliability and safety. Through testing, engineers uncover tensile strength, compressive limits, and elasticity. By comparing these attributes, you can determine which tube aligns with your requirements, ensuring confidence in the final product.

3. Tensile Strength Test

Tensile strength tests measure the ability of a carbon fibre tube to withstand stretching forces. This test applies axial tension to evaluate how much load the material can handle before breaking. Results are critical for applications in aviation or robotics, where failure under load could have dire consequences. A high tensile strength value often signifies resilience, making roll-wrapped tubes an excellent choice for demanding projects.

4. Compressive Strength Test

While tensile strength is vital, compressive strength can’t be overlooked. This test examines how well a carbon fibre tube resists squashing forces. Poor compressive performance could lead to buckling under load, particularly in structural applications. Engineers rely on this data to choose tubes capable of enduring compressive stress, ensuring long-term durability and safety.

5. Roll-Wrapped Tube Results & Considerations

Roll-wrapped tubes are celebrated for their balance of strength and versatility. These tubes exhibit impressive tensile and compressive properties, making them suitable for high-performance settings like aerospace or competitive sports equipment. However, manufacturing variations such as fibre orientation and resin quality impact their performance. Be sure to evaluate test data specific to the supplier’s roll-wrapped offerings. Opt for tubes with uniform strength distribution, particularly if your application involves dynamic forces or cyclic loading.

Réflexions finales

Selecting the best carbon fibre tube hinges on understanding your application’s demands and interpreting test results. Consider the environment, mechanical requirements, and budget to find a solution that checks all boxes. By focusing on these critical aspects, you ensure not only project success but also peace of mind in your choice.