Feuilles de fibre de carbone (feuilles de fibre de carbone pour la vente) sont largement utilisés dans l'aérospatiale, l'automobile et les équipements sportifs en raison de leur légèreté, de leur grande résistance et de leur durabilité. Qu'il s'agisse d'un Feuille de fibre de carbone de 3 mm ou une norme Feuille de fibre de carbone 4×8Leur processus de fabrication est contrôlé avec précision. Cet article explique la production des feuilles de fibre de carbone et répond aux questions les plus courantes telles que comment couper des feuilles de fibre de carbone et Où puis-je acheter des feuilles de fibre de carbone ?.

Méthode 1 : Processus de fabrication des feuilles de fibres de carbone

1. Préparation des précurseurs

Le processus commence par un précurseur (par exemple, le polyacrylonitrile PAN), qui est carbonisé pour former des fibres de carbone.

2. Alignement des fibres

Les fibres sont alignées par pultrusion afin d'assurer l'homogénéité du produit. Matériau de la feuille de fibre de carbone a une grande résistance.

3. Tissage du tissu en fibre de carbone

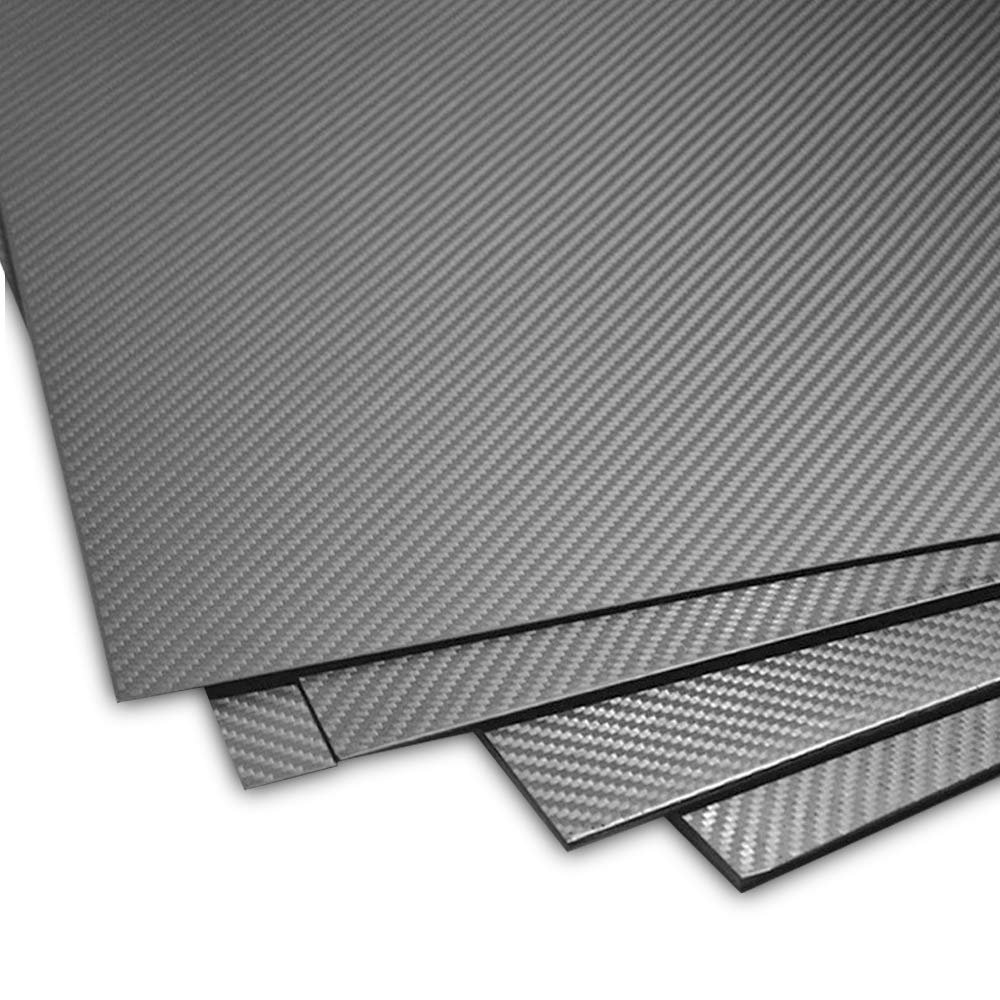

Les fibres sont tissées en tissu (feuilles de fibre de carbone) et le faire durcir à chaud pour obtenir une surface lisse.

4. Imprégnation à la résine

Le tissu est combiné avec de la résine (feuilles de fibres de carbone et résine) pour améliorer la rigidité et la durabilité.

5. Durcissement à la chaleur et à la pression

Enfin, les feuilles sont durcies sous haute pression, formant ainsi des produits tels que Feuille de fibre de carbone 4×8qui peuvent être coupés sur mesure.

Méthode 2 : Traitement et applications

1. Production de fibres de carbone

Les matières premières sont étirées sous l'effet de la chaleur pour former des fibres de carbone, qui sont à la base de la technologie de l'énergie solaire. feuille de fibre de carbone.

2. Mélange de résine et moulage

Les fibres de carbone sont mélangées à de la résine et pressées dans des moules pour créer des tailles standard telles que Feuille de fibre de carbone 4×8.

3. Traitement de surface

Les feuilles peuvent être enduites pour résister à l'eau ou pour protéger contre les rayures, selon les besoins de l'application.

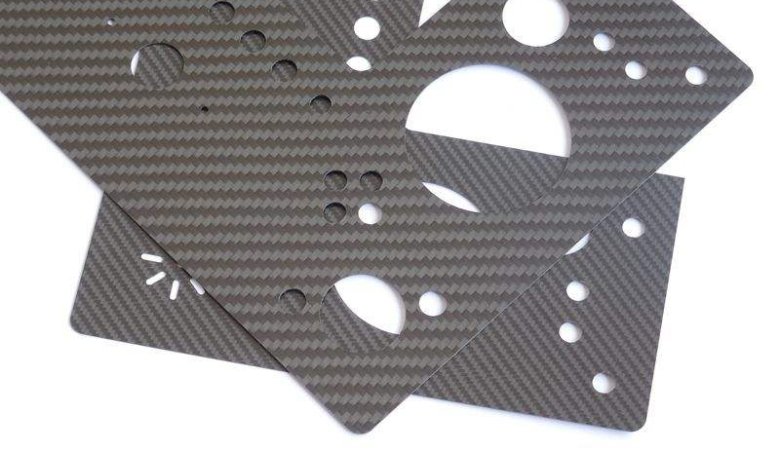

4. Coupe et finition

Les feuilles durcies peuvent être coupées (comment couper des feuilles de fibre de carbone) pour diverses utilisations industrielles ou de bricolage.

Où acheter des feuilles de fibre de carbone ?

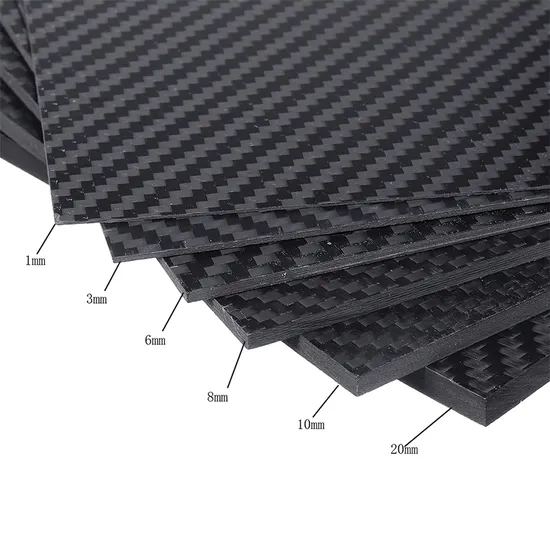

Si vous voulez acheter des feuilles de fibre de carbonePour plus d'informations, consultez les fournisseurs de matériaux composites spécialisés ou les magasins en ligne (par exemple, les sites web des fabricants). Les options les plus courantes sont les suivantes Feuille de fibre de carbone de 3 mm et feuilles de fibre de carbone 4×8L'appareil est adapté à la fabrication de produits industriels, de bricolage et de produits haut de gamme.

Principaux enseignements :

✔ Fabriqué à partir de fibres plastiques chauffées

✔ La résine ajoute de la résistance et de la rigidité

✔ Disponible dans des tailles comme 3mm et 4×8

Facile à découper et à personnaliser

Références :

1.Quelle est la solidité des plaques en fibre de carbone ?

2.Comment choisir la bonne feuille de fibre de carbone pour votre projet ?

3.Utilisation de tiges et de tubes en fibre de carbone dans la technologie des drones

4.Comment choisir les feuilles de fibre de carbone pour les drones ?

5.Quelle est la différence entre les feuilles de fibre de carbone et les plaques de fibre de carbone ?

Une réponse