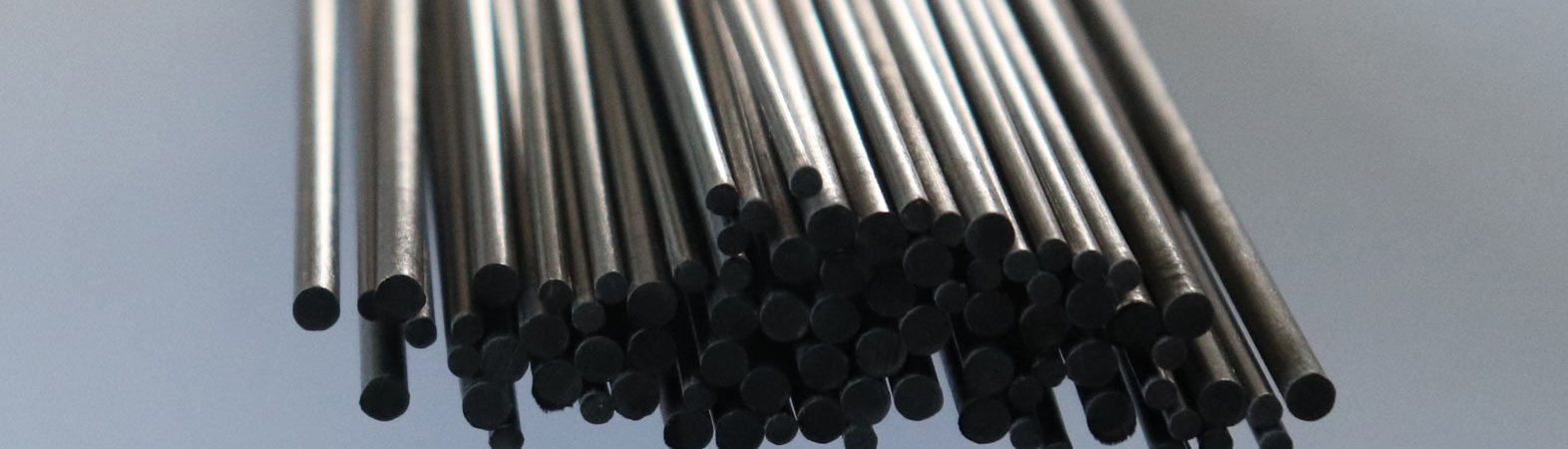

TROUVER UN FABRICANT FIABLE DE TIGES EN FIBRE DE CARBONE

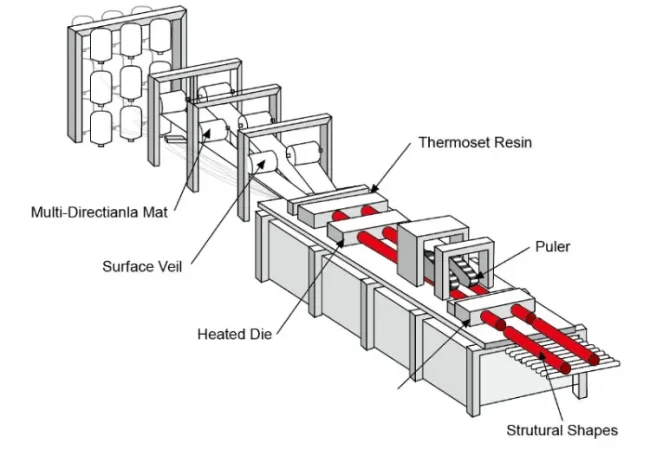

Méthode de pultrusion

Les fibres de carbone sont tirées à travers un bain de résine, assurant une imprégnation uniforme.Le mélange fibre-résine passe à travers une filière chauffée pour former la forme de tige désirée.Le durcissement continu a lieu pendant que la tige se déplace à travers la filière.

Personnalisable

Non seulement la longueur et le diamètre, mais aussi tous les autres aspects peuvent être personnalisés, y compris les câbles de fibres, les finitions de surface (mate, brillante), les qualités (T300, T700, T800) et les formes.

Solution à guichet unique

Avec notre machine CNC, une fois que la tige de fibre de carbone pultrudée est passée par les zones de façonnage et de refroidissement, elle est coupée à la longueur souhaitée à l'aide d'une scie ou d'un autre outil de coupe.

Longueur et diamètre

Le longueur et diamètre d'un tige en fibre de carbone peut être personnalisé en fonction des besoins de l'application. En voici un aperçu :

1. Longueur

- Les longueurs standard sont généralement comprises entre 500mm à 3000mm (0.5m à 3m).

- Des longueurs personnalisées peuvent être produites selon les besoins.

- Certains fabricants proposent des longueurs continues pour des applications spéciales.

2. Diamètre

- Les diamètres courants vont de 0,5 mm à 50 mm ou plus.

- Des microtiges (d'un diamètre inférieur à 1 mm) sont disponibles pour les applications de précision.

- Des tiges de grand diamètre (plus de 50 mm) peuvent être fabriquées pour les applications à forte charge.

Les tiges en fibre de carbone étant personnalisableLa longueur et le diamètre exacts peuvent être adaptés en fonction de la résistance, du poids et des performances requises. N'hésitez pas à me contacter si vous avez besoin de plus de détails !

Tissage

Vous pouvez choisir parmi plusieurs options de tissage pour la couche extérieure afin de répondre à vos exigences mécaniques tout en donnant aux tubes en fibre de carbone un aspect attrayant.

- Tissu sergé

- Tissu uni

- UD (Unidirectionnel)

Finition de surface

Elle est également disponible dans différentes finitions, notamment brillante et mate. La fibre de carbone brillante présente une surface lisse et réfléchissante, ce qui lui confère un aspect élégant et brillant. La fibre de carbone mate présente une surface non réfléchissante et une finition plus douce et plus discrète.

- Brillant

- Semi-mat

- Mat

Traits en fibre de carbone

"K" représente mille et est utilisé pour indiquer le nombre de fibres dans chaque faisceau. Plus le chiffre est élevé, plus le faisceau est large, ce qui se traduit également par des différences d'aspect.

- 1K

- 3K (le plus courant)

- 6K

- 12K

Grade de résistance de la fibre de carbone

Nous comprenons que des applications différentes exigent des niveaux de performance différents. C'est pourquoi nous proposons 3 grades de fibre de carbone parmi les plus populaires pour répondre à vos besoins spécifiques

- T300 (le plus courant)

- T700

- T800

Qu'est-ce qu'une tige en fibre de carbone ?

Les tiges en fibre de carbone comptent parmi les matériaux composites les plus recherchés dans les domaines de l'ingénierie, de la fabrication et des applications axées sur la performance. Plus solides que l'acier, plus légères que l'aluminium et résistantes à l'usure, ces tiges de pointe permettent de relever des défis pour lesquels les matériaux traditionnels ne suffisent pas. Mais qu'est-ce qui les rend uniques ? Comment surpassent-elles les autres matériaux ? Décortiquons les détails d'une manière qui importe à ceux qui recherchent la durabilité, la précision et l'efficacité.

Une tige en fibre de carbone est constituée de filaments de carbone très serrés infusés dans une matrice polymère. Cette fusion crée une résistance à la traction inégalée, une rigidité extraordinaire et une résistance à la fatigue impressionnante. Contrairement au métal ou au bois, les tiges composites résistent à la corrosion, à l'humidité et à la dégradation de l'environnement. Les applications vont de l'aérospatiale aux équipements sportifs, en passant par l'automatisation industrielle et le renforcement des structures.

Pourquoi choisir les barres en fibre de carbone plutôt que d'autres matériaux ?

Léger mais solide - Poids pour poids, ces tiges surpassent l'acier en termes de résistance tout en pesant une fraction du poids.

Résistant à la corrosion - Contrairement aux métaux, la fibre de carbone ne rouille pas, ne se déforme pas et ne s'affaiblit pas dans les environnements humides, salés ou chimiques.

Rigidité exceptionnelle - Leur grande rigidité garantit une précision et une déviation minimale, ce qui les rend idéales pour la robotique, l'automatisation et les outils de précision.

Durabilité dans des conditions extrêmes - La chaleur, le froid et les fluctuations de pression n'affectent pratiquement pas leur intégrité.

Dilatation thermique minimale - Ces tiges conservent leur forme et leur résistance même en cas de fluctuations de température.

Utilisations concrètes des tiges en fibre de carbone

Qu'il s'agisse d'industries de pointe ou d'applications quotidiennes, ces tiges composites offrent des performances inégalées. Voici quelques exemples clés :

Aérospatiale - Supports structurels, structures légères, composants de drones.

Automobile - Renforcements du châssis, modifications pour la course, améliorations visant à réduire le poids.

Sports et loisirs - Cannes à pêche, cerfs-volants, matériel de tir à l'arc, vélos d'appartement.

Construction et architecture - Renforcement du béton, poutres structurelles, supports de pont.

Médical et prothèses - Orthèses légères, aides à la rééducation, instruments chirurgicaux.

Choisir la bonne tige en fibre de carbone

Avec différentes tailles, orientations de fibres et systèmes de résine disponibles, le choix de la tige idéale nécessite une bonne compréhension des besoins du projet. Tenez compte de ces facteurs essentiels :

1. L'orientation des fibres est importante

Barres unidirectionnelles - Rigidité maximale le long d'un seul axe, parfaite pour les applications structurelles nécessitant une résistance élevée à la traction.

Tiges en fibre de carbone pultrudée - L'alignement cohérent des fibres garantit des propriétés mécaniques de premier ordre, ce qui les rend utiles pour les applications de support de charge.

Tissé ou tressé - Souplesse accrue et résistance aux chocs, souvent choisies pour les mouvements dynamiques ou les équipements sportifs.

2. Le système de résine définit les performances

A base d'époxy - Offre une résistance et une longévité supérieures, souvent utilisé dans des applications de haute performance.

Ester vinylique - Plus abordable et offrant une bonne résistance aux facteurs environnementaux.

Phénolique - Résistant à la chaleur et adapté aux applications de sécurité incendie.

3. Le diamètre et l'épaisseur de la paroi déterminent la résistance

Les tiges plus épaisses supportent des charges plus élevées, mais le poids inutile peut réduire l'efficacité. Les ingénieurs optimisent l'épaisseur pour obtenir une résistance maximale avec un poids minimal.

Problèmes courants et solutions apportées par les tiges en fibre de carbone

Problème : Contraintes de poids

Les matériaux traditionnels comme l'acier et l'aluminium augmentent le poids du système, ce qui réduit l'efficacité. Solution : Les tiges en fibre de carbone conservent leur résistance sans masse excessive, ce qui permet d'améliorer les économies d'énergie et les performances.

Problème : Corrosion et dégradation

Le métal s'affaiblit avec le temps en raison de la rouille, de l'exposition et de l'usure. Solution : Les tiges en composite résistent aux conditions difficiles sans se détériorer, ce qui garantit une fiabilité à long terme.

Problème : Flexibilité et instabilité structurelle

Le bois ou le plastique peuvent se déformer de manière imprévisible sous l'effet d'une charge, ce qui peut entraîner une défaillance. Solution : Les tiges en fibre de carbone offrent une rigidité prévisible et des performances constantes.

Pour choisir la bonne tige en fibre de carbone, il faut tenir compte de l'orientation des fibres, du type de résine et du diamètre en fonction du travail à effectuer. Qu'il s'agisse de renforcer un véhicule à grande vitesse, de concevoir un bras robotique léger ou de fabriquer des équipements sportifs de haute performance, les tiges en fibre de carbone s'imposent comme le matériau ultime. Elles remplacent des solutions obsolètes, résolvent des problèmes d'ingénierie critiques et poussent les industries à trouver des solutions plus solides et plus efficaces.

Explorez les options disponibles, adaptez les spécifications aux besoins du projet et découvrez les avantages des matériaux composites de pointe.