Carbon fiber stands out as a versatile material, prized for its strength-to-weight ratio, rigidity, and modern aesthetics. Despite its advantages, the price of carbon fiber often leaves potential buyers hesitating. Understanding the cost factors can help consumers make informed decisions while finding solutions tailored to their needs. So, what drives carbon fiber’s price, and how can customers navigate the market wisely?

Raw Materials: A Pricey Foundation

Carbon fiber begins its journey with precursor materials, primarily polyacrylonitrile (PAN) or pitch. These materials undergo intricate processes to transform into high-strength fibers. PAN accounts for a significant portion of production costs because of its purity and limited global supply. Customers seeking budget-friendly options might explore alternative fiber types, such as basalt or glass composites, although these lack the same performance qualities.

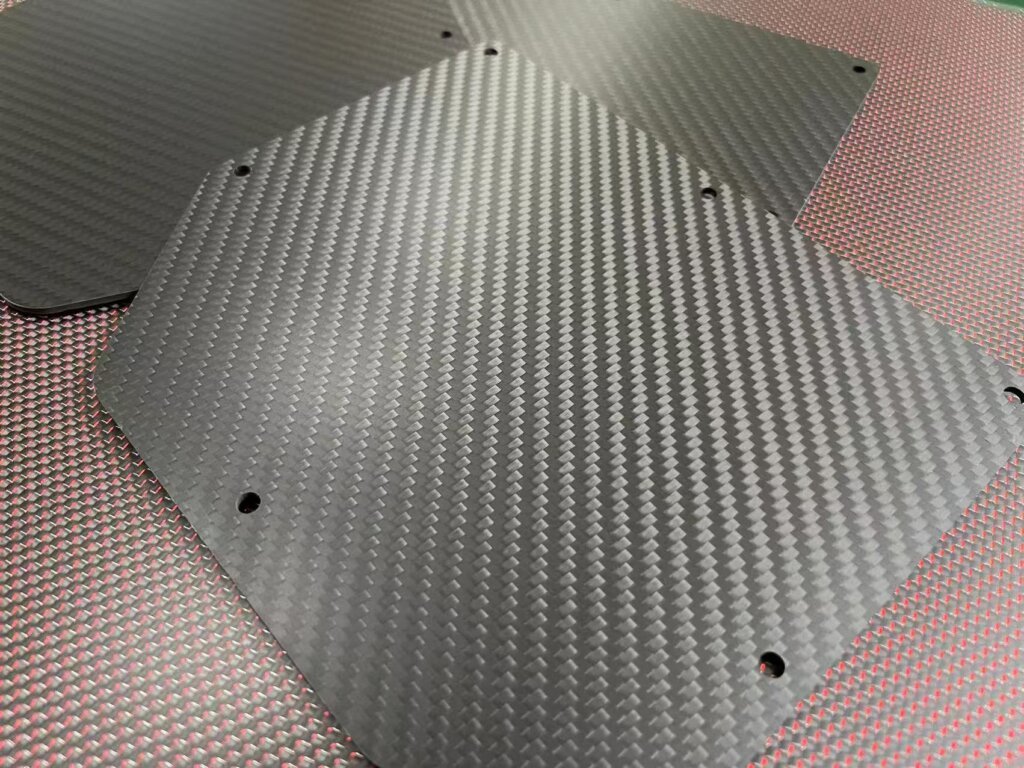

Carbon fiber sheet for car modifications

Production Processes: Precision Comes at a Premium

Manufacturing carbon fiber demands high energy input and advanced technology. The fibers must endure oxidation, stabilization, and carbonization—a series of steps requiring precision engineering and significant time. Factories that optimize these processes with automation can reduce overhead, leading to more competitive pricing for end consumers. Buyers can seek suppliers utilizing such efficiency-focused techniques.

High-strength carbon fiber sheet supplier

Quality Grades and Customization

Not all carbon fiber is created equal. Aerospace-grade fibers, with unmatched strength and lightweight properties, command higher prices compared to standard-grade products used in automotive or recreational equipment. Additionally, customization—whether for unique weaves, finishes, or dimensions—raises costs. Customers should consider their application needs carefully, balancing quality with affordability.

Custom-sized carbon fiber sheet for sale

Supply Chain Challenges

Logistics play a major role in pricing. Sourcing carbon fiber from distant regions or during global supply chain disruptions can inflate costs. By choosing local suppliers or planning orders well in advance, customers can sidestep many unexpected price hikes.

Market Demand and Scalability

Industries like aerospace, automotive, and renewable energy heavily influence carbon fiber prices. When demand spikes, especially for large-scale projects like wind turbine blades, prices soar due to competition for limited supply. Individuals or small businesses can find value by partnering with suppliers who offer batch discounts or stock surplus materials.

Flexible carbon fiber sheet for DIY projects

Environmental Regulations and Innovations

Sustainability efforts introduce both challenges and opportunities. Stricter environmental rules can increase costs, while advancements in recycling technology promise more affordable options in the long run. Customers keen on eco-friendly solutions can explore recycled carbon fiber products, which offer a cost-effective and sustainable alternative.

Lightweight carbon fiber sheet for drones

How Customers Can Save

- Compare Suppliers: Request quotes from multiple vendors to ensure competitive pricing.

- Leverage Bulk Orders: Larger orders often come with per-unit savings.

- Consider Pre-Preg Options: Pre-impregnated fibers streamline manufacturing, which can reduce project costs.

- Explore Hybrid Composites: Combining carbon fiber with less costly materials can provide a balanced solution for specific applications.

Looking Ahead

As technology evolves and production scales, carbon fiber’s cost may decrease, making it accessible for a broader audience. Customers who stay informed about trends, advancements, and market dynamics stand to benefit most from this exceptional material. By understanding the factors influencing price and exploring creative solutions, buyers can achieve the perfect balance between performance and budget.

Do you want know more about carbon fiber ?

Carbon fiber sheet with matte finish?

Heat-resistant carbon fiber sheet panels?

Pre-cut carbon fiber sheet for RC models?

Carbon fiber sheet for industrial applications?

Affordable carbon fiber sheet online?